Pond Plastic Pipe Fittings - PP-R Concealed Porcelain Core Valve with SPT Brand

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Picture:

Product Applications:

Distribution for cool and hot water

Duct for drinkable water system

Pipes for kinds of high-temperature and low-temperature heating system

Pipes for heating and coolling settings in solar energy system

Connecting pipe for air conditioners

Product Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving.

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be30-45days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

Q4:What Is Our Normal Payments Terms?

A4:Our normal payment terms now is: T/T, L/C or western union,paypal

- Q: Can plastic pipe fittings be used for swimming pool installations?

- Yes, plastic pipe fittings can be used for swimming pool installations. They are often preferred for their durability, resistance to corrosion, and affordability. However, it is important to ensure that the fittings are specifically designed for swimming pool use and are compatible with the type of piping and chemicals used in the pool system.

- Q: Are plastic pipe fittings suitable for pharmaceutical manufacturing processes?

- No, plastic pipe fittings are not generally suitable for pharmaceutical manufacturing processes. This is because plastic materials can potentially leach chemicals into the pharmaceutical products, leading to contamination and compromising the quality and safety of the medications. In pharmaceutical manufacturing, it is crucial to maintain strict hygiene standards and use materials that are chemically inert, such as stainless steel or other approved materials, to ensure the integrity of the products.

- Q: How do plastic pipe fittings compare to CPVC fittings?

- Plastic pipe fittings and CPVC fittings have their own advantages and considerations. Plastic pipe fittings, made from various types of plastic such as PVC or ABS, are generally cheaper, easier to install, and resistant to corrosion. However, they may not be suitable for high-temperature applications or where chemical resistance is crucial. On the other hand, CPVC fittings, made from chlorinated polyvinyl chloride, offer increased heat resistance and chemical compatibility, making them suitable for hot water systems and industrial applications. Ultimately, the choice between plastic pipe fittings and CPVC fittings depends on the specific needs and requirements of the project.

- Q: Are plastic pipe fittings suitable for radiant floor heating installations?

- Yes, plastic pipe fittings are suitable for radiant floor heating installations. They are commonly used in such systems due to their flexibility, durability, and resistance to corrosion. Plastic fittings are also easier to install and less expensive compared to metal alternatives.

- Q: Can plastic pipe fittings be used for swimming pool plumbing systems?

- Yes, plastic pipe fittings can be used for swimming pool plumbing systems. Plastic pipe fittings, such as PVC or CPVC, are commonly used in swimming pool plumbing due to their durability, resistance to corrosion, and ease of installation. They are able to handle the high water pressure and temperature variations associated with pool systems. Additionally, plastic pipe fittings are cost-effective and require minimal maintenance, making them a popular choice for swimming pool plumbing.

- Q: What are the different types of connections available for plastic pipe fittings?

- Plastic pipe fittings can be connected using various methods, including solvent welding, compression fittings, threaded connections, push-to-connect fittings, and heat fusion.

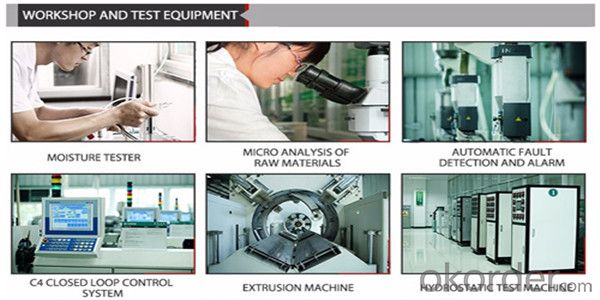

- Q: What are the common testing methods for plastic pipe fittings?

- Common testing methods for plastic pipe fittings include hydrostatic pressure testing, burst testing, tensile testing, impact testing, and dimensional testing. These tests are conducted to ensure the quality, strength, durability, and overall performance of the fittings.

- Q: Can plastic pipe fittings be used for cooling systems in industrial plants?

- Yes, plastic pipe fittings can be used for cooling systems in industrial plants. However, it is important to choose the right type of plastic that can withstand the temperature and pressure requirements of the cooling system. Additionally, using high-quality plastic fittings and ensuring proper installation is crucial to ensure the efficient and safe operation of the cooling system.

- Q: Can plastic pipe fittings be used in fire hydrant systems?

- No, plastic pipe fittings are not suitable for use in fire hydrant systems due to their inability to withstand high pressure and heat.

- Q: Can plastic pipe fittings be used for chemical dosing in water treatment?

- Yes, plastic pipe fittings can be used for chemical dosing in water treatment. Plastic fittings are commonly made from materials like PVC, CPVC, or polypropylene, which are resistant to many chemicals and can withstand the corrosive nature of certain water treatment chemicals. Plastic fittings also offer cost-effectiveness, durability, and easy installation, making them suitable for various applications in water treatment processes. However, it is important to consider the specific chemicals being used and ensure that the chosen plastic fittings are compatible with those chemicals to avoid any potential reactions or leaching.

Send your message to us

Pond Plastic Pipe Fittings - PP-R Concealed Porcelain Core Valve with SPT Brand

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords