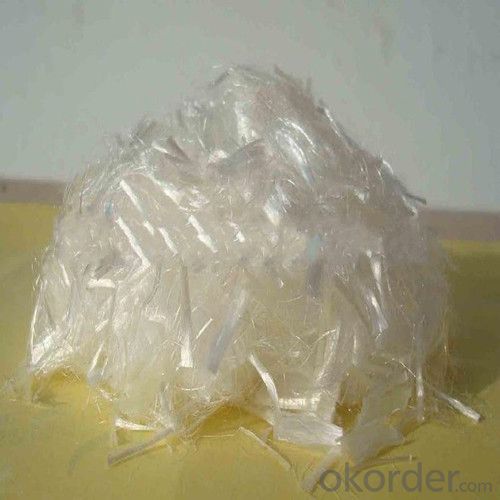

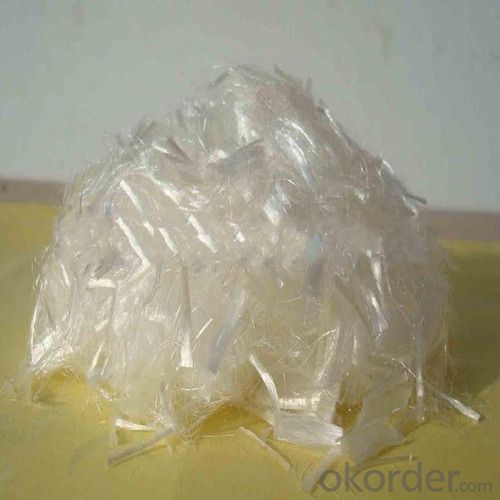

PP Fiber Polypropylene Fiber for Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Fiber for motor

PP Fiber:

it is a fiber with 4shapes mixing with concrete to reinforce the strength of concrete and crack resist.

PP Fiber SUITABLE PROJECT:

A). Projects like concrete road, bridge, airport road and factory floor which strictly require cracking resistance. The life span of these projects will be lengthened for 5-10 years.

B). The walls of tunnels, mines, roofs and reservoir projects with special construction. When using spray technology in concrete construction, the PP fiber added into the concrete can effectively decrease the spray concrete's deformation rate of the walls less than 8% and that of the roof less than 12%, and also can reduce the friction. It can improve the constructing efficiency and working environment and popularize the spray technology.

C). River courses and dams, etc. The PP fiber can improve concrete's resistance to crack and squirt and wear to lengthen projects' life span.

D). Military defense works, dock banks and piers, etc. This fiber can greatly strengthen the concrete's spurt resistance and heighten these projects' safety and lengthen their life pp fiber for motor

it is a fiber with 4shapes mixing with concrete to reinforce the strength of concrete and crack resist.

PP Fiber FUNCTION:

Increase seepage resistance

Prolong endurance

Improve steel protection

Increase cracking resistance

Increase fire resistance

Strengthen spurt & fatigue

Improve tensile, bending & folding strength

Improve plastic deformity

Strong acid & alkali resistance and good endurance

PP Fiber SPECIFICATION:

| Material | Polypropylene |

| Density(g/cm3) | 0.91 |

| Elastic Modulas (MPa) | 3500min. |

| Width (mm) | 5 |

| Thickness (mm) | 0.035 |

| Length(mm) | 12, 15, 20, 38 |

| Equivalent Diameter (um) | 100 |

| Shape | Beam-like Net |

| Crack Elongation(%) | 10min. |

| Acid &Alkali Resistance | Strong |

| Water-Absorbency | No |

| Tensile Strength(MPa) | 560-770 |

| Melting Point(°C) | 160-170 |

APPLYING INSTRUCTION:

Length : Generally, the proper length of the fiber added into concrete is 20 mm, and in the spray concrete is 10mm.

Ratio Design: Usually the proper amount of fiber to concrete is 0.9kg/m3 , and the water-proof layer of the bridge requires 1.35-1.8kg/m3, and the spray concrete in the tunnel is also the same and other materials remain the same. The ratio of fiber and concrete can be determined by tests for special purposes. The fiber has better effects on the concrete with active compound materials, such as silicon ash, coal powder, ground slag and zeolite powder.

Mixer Adoption: Double-axle horizontal compelling mixer is better and self-dropping cylinder mixer can be used, too.

Mixing Process: Crushed stones, fibers and sands are put into the mixer in succession. After stirring for two minutes, fiber will fully spread and then add cement and water and stir normally. The addition of materials also can be put into as usual, but the stirring time should be properly prolonged to make fiber completely mixed.

Stirring Time: The purpose of the stirring is to make fiber fully spread into monofilament or the net fully spread, so generally the stirring time is 2-3minutes after the addition of polypropylene fiber-mes

Packing:

0.9kgs per bag, 14bags per carton

Or 0.9kgs net per packet, 12packet per bag.

Quantity: 400CTNS/20`FCL;

828CTNS/40`FCL;

980CTNS/40`HQ

Send your message to us

PP Fiber Polypropylene Fiber for Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords