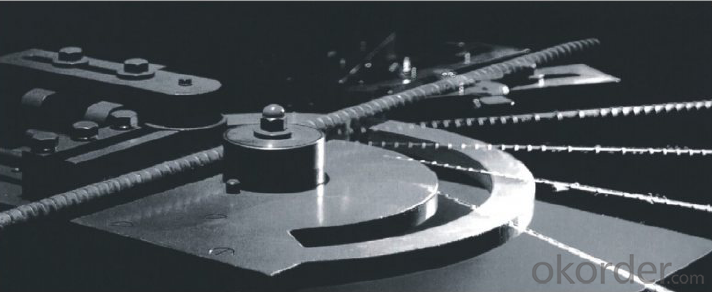

Portable Steel Bar Cutter & Bender GW50

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1. GW40 enclosed type rebar cutting machine is our new product that is improved and manufactured on the basis of the original open reinforcing steel cutter according to requirements of customers.

2. It has enclosed lubrication system and clutch structure, which make it easy to operate and maintain.

3. It also has the advantages of safety, high efficiency, light weight, and energy economy.

4.It is a part of the indispensible equipment in construction and metal processing industries.

5.It can be used to cut plain round steel bars, deformed steel bars, and steel sections like flat steel and square steel.

Main Product Features:

1.Possess quality certification of ISO 9001:2000. Can pass CE test.

2. A wide range of specifications for you.

3. We can supply OEM service and can also produce according to your requirements.

4. Seaworthy packing or as customers’ request.

5. Hydraulic tester & artificial detection.

Product Specifications:

Model: GW50

Round Steel: 6mm-50mm

Grade Spinal Steel: 6mm-42mm

Voltage: 380V

Motor Power: 4kW

Speed of Mortor: 1440r/min

Bending Speed: 3-15r/min

Weight: 400kg

Dimension: 110 x 85 x 85cm

FAQ:

Q1: How to confirm that your Cutter could be used in our country?

A1: We have been providing Cutter for nearly ten years, possess near every kind of Cutter in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Cutter according to customers request?

A4: Yes, we can produce Cutter according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: Do you pay tax on excavators, bulldozers, graders? How much should I pay for it? What's the tax amount?

- you'll have to pay the mechanical life of all taxes, why do you say that, because of the expensive machinery ridiculously.

- Q: The grader flue injection going on?

- April 3, 2009... I am a Anhui Ji Chaohu grader driver, has 11 years of driving and maintenance experience, driving after work 160A, 160C, Xugong 165 etc.... Grader job search:

- Q: 180 grader and 160 grader, what's the difference, please industry experts, thank you

- The power of the engine is different. 180 with WG180 and WG200 gearboxes. 160 with its YD13 series gearbox.

- Q: Asphalt paver asphalt mixer jacking machine grader about how much money ah

- Asphalt paver 10000Asphalt mixer 40000Pipe jacking machine 30000Grader 35000That's about it. Different brands have different prices.

- Q: Tiangong 200 grader, how much can you sell for 5 years?

- About 400 thousand or so you can search the peak of heavy machinery limited company, with advanced technology products, absolutely, the first grader is from R & D, is the predecessor of Chinese day, was first introduced from Germany, the digestion and absorption of innovation has formed a series of products, the introduction for the purpose of nuclear test after flat cover of contaminated soil...

- Q: Now Xugong 170 grader is how much money? Xugong 140 roller type how much money? Thank you

- Liugong turntable is fully closed, maintenance free, this item in the future use of a lot of money.

- Q: What are the factors that affect the flatness of graders?

- The factors that affect the smoothness of bridge pavement 1. the mixing quality of concrete quality and concrete is one of the important factors that affect the smoothness of pavement. Concrete mix is not accurate, than the measurement of mixing quality does not meet the requirements and water content detection frequency on aggregate enough will affect the scene of the slump and workability of concrete, resulting in uneven density, resulting in poor planeness of bridge deck pavement. (1) if the mix proportion not allowed, aggregate fluctuated, the amount of sand or less time, will affect the concrete slump and workability, resulting in uneven density, resulting in uneven shrinkage of concrete. (2) the concrete slurry is uneven content as everyone knows, the fresh concrete under certain temperature conditions, capillary water, free water and continuous evaporation, concrete gradually began to shrink, the shrinkage phenomenon mainly occurred in the slurry, if this contraction is uniformly, so its surface roughness does not produce little effect or influence what if; fresh concrete water cement ratio of cement paste is too large, too much, and the water cement ratio and slurry mixture in distribution or mixing uneven, concrete shrinkage is also uneven, resulting in uneven pavement.

- Q: What is the low pressure of the gearbox in Grader?

- Is the automatic variable box, the main oil circuit, low oil pressure? Generally the pressure of the oil pump, low pressure valve or oil drain place, a kind of check

- Q: Well, compare the two of them. 10For example, they are difficult to operate, how long should learn how to learn the monthly salary? Wait... There are experts in this area to help answer my brother, it is best to detail a bit, because I am no layman oh. Thank you all, brotherLet me know who knows this

- Good teacher a few days to digging machine safety skills, maintenance work, the apprentice can let go dry, flat machine master to teach, a few centimeters, personal feeling on their own, someone not good, some people live out about what March. I took the 9000 highest paid digging machine, flat machine master took 12000, I was 8000, single day digging 300, flat 500.

- Q: What is the function of Grader?

- Grader has the functions of relieving the road surface, removing snow, pushing the soil and loosening the soil

Send your message to us

Portable Steel Bar Cutter & Bender GW50

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords