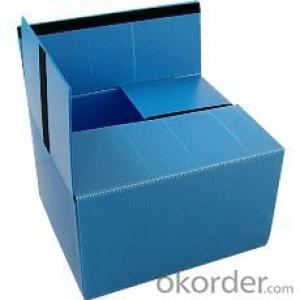

Polypropylene Hollow sheet Delivery Box with different sizes and colors

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polypropylene Hollow sheet Delivery Box

Description | PP hollow sheet/PP corrugated sheet is a kind of environmental material, which is pollution-free and recyclable, made of polypropylene (PP) and polyethylene (PE) | |||||||||

Width | ≤2100mm | |||||||||

Length | As required. | |||||||||

Thickness | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 9mm | 10mm | 11mm | 12mm |

GSM | 250-500 | 300-600 | 600-900 | 800-1200 | 900-1600 | 1400-2000 | 1600-2000 | 1600-2200 | 2200-2400 | 2400-2600 |

Application | Packing | Transfer Box,mail box,display rack,partition,gift box,food packing,turnover box,dustbin,etc. | ||||||||

Advertising | Sign board,exhibition board,billboard,caution board,picture frame backing,digital printing and screen printing. | |||||||||

Decoration | Partitions,wall cladding,indoor and outdoor decoration,windows and false ceilings,floor cover,greenhouse roof. | |||||||||

Stationery and art design | It has multi-color,suitable for art design & various pattern box or delicate gift pack. | |||||||||

Feature | Light weight,rigid,strong and long time durable. | Waterproof,moisture resistance,excellent weather ability. | ||||||||

Chemical resistance,anti-impact,fade resistance. | Environmental friendly,recyclable,washable,non-toxic. | |||||||||

Easy to fabricate,custom-made cut shape. | Excellent surface for paints and inks easily,anti-corrosion. | |||||||||

Grade | Common,Corona Treated,Anti-Static,Conductive,UV Stabilized,etc. | |||||||||

Color | Clear,Black,White,Blue,Red,Yellow,Green,Pink,Or as required. | |||||||||

Advantage | Capacity:600MT per month; Prompt delivery; Factory Direct Selling; ISO-9001 | |||||||||

- Q: What kind of wood is commonly used in wooden packing boxes?

- The frame wooden structure can be divided into class I (within the frame wooden box): frame member in the inner box board, suitable for general contents; class II (frame wooden box): frame structure in the outer box plate, applies in the length direction as a whole, and has sufficient rigidity to the contents. The basic provisions of its design consider the usual conditions of transportation, loading and unloading and storage.

- Q: What are the standards for carton boxes?

- 1, the printing quality, printing pattern: handwriting clear, consistent color, bright light; printing position error box does not exceed 7mm, the box is not more than 4mm;2, sealing quality: no holes around the box, the box lid closed, no staggered and off the seam;3 dimensional tolerances: box diameter and design tolerances should be kept in the big box small box + 5mm, + 3mm, basically the same size;4, fold the number of fold: corrugated box shake lid opened, 180 degrees, reciprocating folding more than 5 times, the one or two types of box surface and inner layer, and three types of box, the total length of cracks in the box is not greater than 70mm;In addition, requirements for joining specifications, neat edges, no overlapping angles, and no obvious damage or stains are allowed on the box surface

- Q: How can the packing box be mounted onto the board?

- There are two kinds of steel box: one is a steel belt with a tray, and two is a wooden box without a tray. Compared with the traditional wooden case, its characteristic is: it is easy to disassembly, reliable connection: products can be folded after storage, and the use of steel edge connection, greatly reducing the transportation cost, effectively saving storage space. It is a good choice for long-term transportation and long-term storage. It is suitable for packing articles under the weight of 2 tons. Usually, the box can be split into six pieces (S type) or three (P), which is easy to transport and assemble when used. The length is usually around 300mm - 2000mm.

- Q: Can the express company provide the computer's packing box?

- Some can, and some will not provide, specifically ask the courier company. It costs a lot of money to add a box... You'd better get the box to tell the truth, I suggest you host your own bag Kazakhstan is not too heavy that the flat display handled well, home for an LCD flat screen, or not good? Not expensive (second-hand) you ha go logistics account money, you have enough to buy a flat screen display.

- Q: What kind of material does the packing case have?

- Generally used as a mid-range packaging method, between the inner packing and the outer packing. Color package boxIt is usually made up of several colors, giving a strong visual sense, so that buyers and users can understand the details of the overall appearance and color of the goods. Especially suitable for the purchase of goods before we can take. It has been widely used in electronics, food, beverage, wine, tea, tobacco, medicine, health care products, cosmetics, small appliances, clothing, toys, sporting goods and other products packaging industry and supporting industries, is an indispensable industry.

- Q: What enterprises need wooden packing box?

- We need wooden packing boxes for the production of various instruments, glass products, machinery factories and so on;The packing box is a national standard drafting unit of GB/T 7284-1998 frame wooden box, which is protected by national standard according to the characteristics of the goods transported or loaded. The box made of plates, and other components of the gear box.

- Q: What's the square of the packing box?

- Material classification1. packing container made of wood and bamboo in wooden packing case2. non fumigating packing box made of composite material3. strong plastic packaging container safety box for patent engineering plastics made by special technology.4. corrugated packaging box is through die cutting, indentation, nail box or sticky box made of corrugated cardboard boxes. Corrugated box is one of the most widely used packing products.

- Q: How about a carpenter's packing case?

- The vertical direction of the core plate (the difference between the core and the material) is poor, but the lateral flexural strength is higher. Both nail grip and water repellency are availableBetter than MDF and chipboard. The surface is generally rough and needs finishing (paint or decorative panels etc.). Simply speaking,A large piece of carpentry that must be nailed at home usually requires a large core board.But the large board itself uses a lot of glue, and a lot of glue or paint will be used in the finish, and the core boardPollutants are in open volatile state, so, home improvement must strictly control the use of large core board.

- Q: What are the general requirements for packing the goods by air?

- In addition to the goods packed in paper bags (such as documents, data, etc.), the checked goods should be packed with packing straps. It is prohibited to use straw bags or rope strapping goods packaging. F. the packing belt used for the binding of the goods shall be able to bear all the weight of the goods and shall ensure that the goods are not broken when they are carried.

- Q: What are the requirements for product packaging?

- When the product quality in more than 50kg or packaging volume is above 1m3, must be in the corner of the box body file on the iron nail wrap angle for packaging end plate for the entire board and gratuitous file boxes, fiberboard box and power transmission control equipment, in the wooden box after sealing nail, must steel fastened around in wooden cases, wooden box at each end of a nail.From the date of shipment, under normal storage and transportation conditions, the protection period of the package is 1 years. In the meantime, the packaged product shall be intact.

Send your message to us

Polypropylene Hollow sheet Delivery Box with different sizes and colors

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches