Polycarboxylate superplasticizer made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

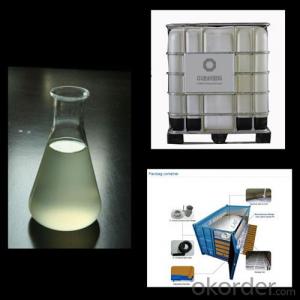

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polycarboxylate superplasticizer made in China

It can be applied in a wide variety industry and can improve the workability to the concrete and to improve

high early compressive strength, even with low water/cement ratios while maintaining normal levels of

workability.

It can be widely used in conventional concrete, pumping concrete, super-fluid self-compacting and

high-performance concrete; it has the excellent performance especially in the application of high-

strength high performance concrete.

.

HL-800 is suitable for ready-mixed, pumping, hot weather concrete and the precast elements used in the construction which requires good workability and high early and final strengths. It can be applied in the preparation of various concrete of C40 and above grade with low water/cement ratio. When applied in preparation of concrete of higher than C80, it is recommended to conduct tests before bulk production.

Properties

Items | HL-800 |

Appearance | Colorless or light yellow liquid |

Density(g/cm3) | 1.09±0.02 |

pH value(%) | 4~7 |

Solid Content (%) | 40~50±1 |

fluidity of cement(mm) | ≥240 |

chlorine ion content (according to solid content changing)(%) | ≤0.02 |

Total alkali Content (according to solid content changing)(%) | ≤2 |

formaldehyde content (according to solid content changing)(%) | ≤0.01 |

Features and Benefits

1. Excellent compatibility with various types of cements.

2. High water reducing rate, low dosage, and low slump loss.

3. Low chloride and alkali content, no corrosion to steel-bar

4. High stability: no precipitation at low temperature.

5. Environmental friendly and nontoxic

Dosage

This product recommended content is 0.25% -0.85% of the total weight of cementitious

material, actually content should be experimentally determined.

Send your message to us

Polycarboxylate superplasticizer made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords