Perovskite Solar Cells - Favorites Compare A Grade 300W Solar Panel with Frame and MC4 Connector

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 watt

- Supply Capability:

- 10000000000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

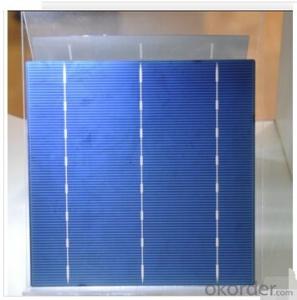

| Place of Origin: | Guangdong China (Mainland) | Brand Name: | CAP | Model Number: | 50w100w150w200w250w300w |

| Material: | Monocrystalline Silicon | Size: | 1385*1035*75mm | Number of Cells: | 72pcs |

| Max. Power: | 300w | type: | solar panel | color: | blue&black |

| warranty: | 5 years |

Packaging & Delivery

| Packaging Detail: | standard export package for solar panel |

| Delivery Detail: | 7-15 days for solar panel |

Specifications

solar panel

High Efficiency

25 years Warranty

High-transmissivity low-iron tempered glass

Solar Panel

50w100w150w200w250w300w

Characteristics

1,High and stable conversion efficienly based on over 4 years professional experience

2 ,High reliability with guaranteed +/-10% output power tolerance

3,Proven materials,tempered front glass,and a sturdy anodized aluminum frame allow modules to operate reliably in multiple mountily configurations

4,Combination of high efficicncy and attractive appearance

Quality and Safety

1,25 year 80%,10 year 90% power warranty 3 year power warranty

2,ISO9001:2000 (Quality Management system) certified factory

3,Product Quality warranty & products Liability Insurance to guarantee and user' benefits

4,Certifications TUV Intercert, CE Temperature Coefficients

| Module Type | 100w | 150w | 200w | 250w | 300w |

| Maximum Power at ST(Pmax)W | 100wp | 150wp | 200wp | 250wp | 300wp |

| Maximum Power Voltage(Vmp)V | 36/18 | 36/18 | 36/18 | 30.8v | 36/18 |

| Maximum Power Current(Imp)A | 2.77/5.55 | 4.16/8.33 | 5.55/11.1 | 8.11A | 8.33/16.66 |

| Open Circuit Voltage(Voc)V | 39.5/19.05 | 39.3/19.4 | 39.6/19.5 | 36.2V | 39.6/19.8 |

| Short Circuit Current(Isc)A | 3.04/6.09 | 4.58/9.16 | 6.1/12.2 | 8.7A | 9.16/18.33 |

| Cell Efficiency(%) | 18.60% | 18.10% | 18.60% | 17.80% | 18.10% |

| Module Efficiency(%) | 17.70% | 17.20% | 17.70% | 17.10% | 17.20% |

| Operating Temperature°C | -40°C to +85°C | -40°C to +85°C | -40°C to +85°C | -40°C to +85°C | -40°C to +85°C |

| Maximum system voltage | 1000V(IEC)DC | 1000V(IEC)DC | 1000V(IEC)DC | 1000V(IEC)DC | 1000V(IEC)DC |

| Power tolerance | -0.03 | -0.03 | -0.03 | -0.03 | -0.03 |

| Temperature coefficients of Pmax | -0.45%/°C | -0.45%/°C | -0.45%/°C | -0.45%/°C | -0.45%/°C |

| Temperature coefficients of Voc | -0.27%/°C | -0.27%/°C | -0.27%/°C | -0.27%/°C | -0.27%/°C |

| Temperature coefficients of Isc | 0.05%/°C | 0.05%/°C | 0.05%/°C | 0.05%/°C | 0.05%/°C |

| Weight(kg) | 8 | 11 | 14 | 20 | 25.5 |

| Number of cell(pcs) | 4*9 | 4*9 | 6*10 | 6*12 | 6*12 |

| Dimensions(mm) | 1194*534*35/30 | 1580*808*50/35 | 1471*670*40/35 | 1640*992*50 | 2000*1050*50 |

Making More Solar Cells from Silicon

Silicon wafers are the conventional solar cells–they’re what absorbs sunlight and generates electrons. Yet the way wafers are currently manufactured wastes half of the expensive, ultra-pure crystalline silicon they’re made from. When large ingots of silicon are cut into hair-thin wafers, waste silicon is lost as sawdust. The new process–details of which remain secret–produces wafers directly from molten silicon without any sawing. This saves material and reduces the number of steps needed to make solar cells, both of which bring down costs.

How to Grow "Silicon" Crystals to Make Solar Cells

In industry, silicon crystals are grown to form a uniform cylinder of silicon which is used as the base material for crystalline solar cells. There is plenty of silicon about on the earth, in fact, as mentioned previously, after oxygen it is the second most abundant element. When you think that sand and quartz all contain silicon and then imagine the amount of sand in the world, you begin to realize that we are not going to run out of silicon in a hurry!

The problem with sand is that it also contains oxygen in the form of silicon dioxide, which must be removed.

The industrial process used to produce silicon requires temperatures of around 3270oF (which is about 1800oC). Obviously we can't experiment with these3 sorts of temperatures at home - but we can recreate the process!

You are going to need a saturated sugar solution; this will sit in the lid of your coffee jar. Now, take a large crystal of sugar, often sold as "rock sugar" and "glue" it to the end of the skewer. Next, drill a hole the same diameter as the skewer, and poke the skewer through the bottom of the coffee jar. Stand it on a windowsill and lower the crystal into the saturated sugar solution. Over some time, crystals should start to grow - pull the skewer up slowly, bit by bit, so that the growing crystal is still in contact with the sugar solution. This is just like the way that silicon is grown. The silicon is drawn up slowly from a bath of molten hot silicon (which is analogous to our saturated sugar solution).

Once this large crystal of silicon has been manufactured, it must be cut into slices to manufacture the solar cells.

- Q: Can solar cells be used in developing countries?

- Yes, solar cells can be used in developing countries. In fact, they are increasingly being used as a cost-effective and sustainable solution to address the energy needs of these countries. Solar cells provide access to electricity in remote areas where traditional grid infrastructure is unavailable or unreliable. They can power homes, schools, healthcare centers, and other essential services, improving living conditions and fostering economic development. Additionally, solar energy is abundant and renewable, reducing dependence on fossil fuels and mitigating climate change impacts.

- Q: What is the solar cell production process

- Solar cells are the core devices in the PV power generation system. Energy saving is a kind of device that uses the principle of photoelectric conversion to convert the radiated light of the sun into electrical energy through the semiconductor material. This photoelectric conversion process is usually called "photovoltaic effect", so the sun

- Q: What is the difference between a monocrystalline and polycrystalline solar cell?

- The main difference between a monocrystalline and polycrystalline solar cell lies in their composition and manufacturing process. Monocrystalline solar cells are made from a single, high-purity silicon crystal. This results in a uniform structure with a consistent and orderly arrangement of atoms. Monocrystalline cells are known for their high efficiency and sleek appearance, as they typically have a black or dark blue color. On the other hand, polycrystalline solar cells are made from multiple silicon crystals. These crystals are smaller and not as perfectly aligned, leading to a more random arrangement of atoms. Polycrystalline cells are usually recognizable by their bluish hue and a fragmented appearance. In terms of efficiency, monocrystalline solar cells tend to have a slightly higher efficiency rate compared to polycrystalline cells. However, recent advancements in technology have narrowed this efficiency gap, and polycrystalline cells are now approaching the efficiency levels of monocrystalline cells. Another difference is the cost. Monocrystalline solar panels are generally more expensive due to the higher purity of silicon required and the more complex manufacturing process. Polycrystalline panels, on the other hand, are more cost-effective and offer a lower price per watt. In summary, while monocrystalline solar cells have higher efficiency and a more uniform appearance, polycrystalline cells are more cost-effective and have made significant improvements in efficiency in recent years. The choice between the two ultimately depends on individual preferences, budget, and specific project requirements.

- Q: Can solar cells be used in shopping centers?

- Yes, solar cells can be used in shopping centers. They can be installed on the rooftops or in parking lots to generate clean and renewable energy to power the shopping center's operations. Solar cells provide cost savings on electricity bills and reduce carbon emissions, making them an environmentally friendly choice for shopping centers.

- Q: Can solar cells be used in satellite or space exploration missions?

- Yes, solar cells can be and have been used in satellite or space exploration missions. Solar cells convert sunlight directly into electricity, making them a reliable and efficient source of power for satellites and space probes. They are lightweight, durable, and ideal for harnessing energy in space where traditional power sources are not feasible.

- Q: What is the role of silicon in solar cells?

- The role of silicon in solar cells is to act as a semiconductor material that can absorb sunlight and convert it into electricity through the photovoltaic effect. Silicon is the most commonly used material in solar cell manufacturing due to its abundance, stability, and ability to efficiently convert sunlight into electricity. It forms the basis of the p-n junction, which allows for the separation and movement of electrons and holes, generating an electric current.

- Q: Can solar cells be used in disaster response vehicles?

- Yes, solar cells can be used in disaster response vehicles. They can provide a reliable and renewable source of power to charge essential equipment and devices, such as communication systems, lights, and medical equipment. Solar cells are especially useful in remote or off-grid areas where traditional power sources may be disrupted or unavailable during a disaster.

- Q: What are the disadvantages of using solar cells?

- Some disadvantages of using solar cells include high initial costs, intermittent energy production due to weather conditions, the need for large areas of land for installation, and the production of toxic materials during manufacturing. Additionally, solar cells have lower efficiency compared to traditional energy sources and may require additional energy storage systems for uninterrupted power supply.

- Q: How to get high voltage and high current output of solar cells?

- If you want to get the high voltage and high current output of the solar cells, you can put them in serial and serial-parallel approaches.

- Q: How do solar cells impact energy poverty?

- Solar cells can have a significant impact on energy poverty by providing access to clean and affordable electricity in areas with limited or no grid connectivity. They enable the generation of renewable energy, reducing reliance on fossil fuels and expensive and unreliable energy sources. Solar cells also empower communities to become self-sufficient, improving living standards, promoting economic development, and enhancing educational opportunities. By harnessing the power of the sun, solar cells play a crucial role in addressing energy poverty and promoting sustainable development.

Send your message to us

Perovskite Solar Cells - Favorites Compare A Grade 300W Solar Panel with Frame and MC4 Connector

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 watt

- Supply Capability:

- 10000000000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords