Papaer Grade NANO-Zinc Oxide

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- 6000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production method Of Paper Grade NANO-Zinc Oxide:

With the rapid development of industrial and agricultural economy, the demand for special paper has been diversified, and it has put forward higher requirements. Zinc oxide in the paper industry is mainly used in anti-water, anti-bacterial, anti-static, anti-aging and flavoring, fire-retardant, color paper and other functions of the development of nano-Zinc oxide gradually be applied as a paper additive.

Application Of Paper Grade NANO-Zinc Oxide:

The zinc oxide for papermaking, it can be used in the zinc oxide printing plate, zinc oxide paper production.

1. It is small granule, easy to disperse. It can make printing plate homogenized, fine and smooth

2. Zinc oxide is luster pure white and tinting strength. It can increase the paper white degree, also has advantageous for the colored paper coloration

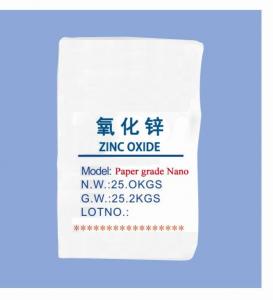

Packing and storage:

This product is packed with plastic-lined and plastic-coated woven bags, 25kg per bag. This product should be keep from breakage, moisture, pollution and contact with acid.

Product quality standards: GB/T 3185-92

ITEM | Quality | ||

131 | 132 | 133 | |

ZnO/% ≥ | 99.0 | 97.0 | 95.0 |

Grain nm≤ | 20 | 57 | 100 |

XRD /nm≤ | 20 | 52 | 100 |

Surface proportion (㎡/g)≥ | 60 | 62 | 65 |

Join index≤ | 50 | 60 | 100 |

Lead oxide( Pb )/%≤ | 0.0005 | 0.0005 | 0.0005 |

Manganese Oxide /% ≤ | 0.0001 | 0.0001 | 0.0001 |

Cupric oxide(Cu)/%≤ | 0.0001 | 0.0001 | 0.0001 |

Cd/%≤ | 0.0002 | - | - |

Hg/%≤ | 0.0001 | - | - |

As/%≤ | 0.0001 | - | - |

105℃volatile substances %≤ | 0.30 | 0.4 | 0.5 |

Water dissoluble % ≤ | 0.10 | 0.41 | 0.5 |

Hydrochloric acid insoluble %≤ | 0.02 | 0.02 | 0.02 |

Burning decrement %≤ | 2 | 2 | 2 |

- Q: What benefit was there to have lead in paint?

- They used it as a pigment. Lead was also added to paint to speed drying, increase durability, retain a fresh appearance, and resist moisture that causes corrosion

- Q: Who invented the paint solution

- At the beginning, the pigment was found, not invented. Only after the human can be chemical synthesis, only the emergence of the so-called synthetic pigment. From this point, the broad sense of "paint" is not invented. Only a narrow sense of a special "pigment", it may be someone or a company invented.

- Q: How are artist paints differ from building paints?

- Building paints generally are mixed using readily available pigments of primary shades plus black and white which are added to either an Oil, Alkyd or Acrylic Base. Depending on whether the paint is used for interior or exterior, and relative to the amount of wear and tear on the paint, it could contain Teflon for wear ability, UV filters to prevent fading, etc. The polymer used in commercial Acrylic paint dries considerably slower than that used in Artists Acrylics. This is actually a blessing, that I've used to my advantage over the years. It's handy to use a white acrylic enamel interior paint for mixing with Artists acrylics when working on skies, water, or any large areas that require blending as it gives a smooth transition. Have done this for years. Artists pigments, depending on the quality of the paints you are using come from a variety of sources, everything from rocks, to plants, to fish, to bugs, and the list goes on. Depending on the source, some of these pigments are very rare and very expensive, making it uneconomical to use in commercial paint production. Hope this answers your question and hopefully gives you a couple of ideas that you might use.

- Q: What is the difference between painting and painting? Which is better?

- Painting is relatively convenient.

- Q: Originally used in the pigment ink is also good, but the price is high, would like to change a little cheap, are bought OKorder, buy free heating coated paper paper

- Different inks can not be mixed. Otherwise the light is color, heavy block the nozzle.

- Q: Can acrylic paint be used to paint a mural on top of a wall that has been painted using oil based paint? I am painting my room blue with oil paint and i want to paint some planets and stuff over it with acrylic,but the wall itself is being painted with oil paint.

- know what yuou know

- Q: What is the difference between a dye and a pigment-based printing ink?

- The dyestuff is dyed, but the pigment is different, and the pigment can be used to make dyes and all the raw materials of monochrome and mixed colorants made of pigments. Simply put the pigment is the raw material of all colored materials. Pigment of the three primary colors are yellow, magenta, cyan. The rest of all the colors are mixed by the three colors from the mix, such as yellow plus magenta is equal to red, yellow plus green is equal to green, yellow plus red and blue is equal to black, these are the three primary colors are mixed, the three primary colors are not equal Mixing can get all the colors in the world.

- Q: How to stain the sheets, dyeing principle is not the same as the clothes, bed sheets bedding tattoo what dyes, art shops have to sell these dyes

- You do not have this kind of dye, even if there is, you can not print. This is not hand-painted. Even hand-painted, finished can not use.As the number of hand-painted paint will affect the fabric feel, touch Up feeling uncomfortable.

- Q: I recently became interested in painting but am not sure what paint to buy for painting on canvas. There are so many different kinds of paint which make it that much hard to decide. Please Help!

- Oils and acrylics are your best bet for painting on canvas. I've worked with both, and each have their advantages and disadvantages. Oils take FOREVER to dry. (Some take up to a week, even longer.) This is bad if you're impatient, but it's also good if you paint one day, stop, and then come back the next to finish. (Your paint will still be wet on your canvas AND your palette.) Oil paints are pretty toxic, so be careful when you work with them. Also, you'll need a mineral spirit/paint thinner of some sort to clean out your brushes. (Try to get odorless mineral spirits if you can. Either way, you'll still need good ventilation when working with oil paints.) If you want to thin your paint, I recommend using an oil painting medium instead of the paint thinner. It'll add some oomph to your piece. Acrylics are great to work with too. They dry pretty fast, can be thinned and cleaned up with water, and are quite a bit safer than oils. (They turn to plastic when they dry, so be careful not to get any on your clothing or else it probably won't come out.) Hope that helps!

- Q: Everyone's paint and paint are where to buy it

- Most of the people are building materials market, and some are directly recommended by the decoration company, regardless of now can also order online, choose a safe, cost-effective decoration coating is very important, Rui Peimu smart paint wish you a happy family, chicken years Big!

1. Manufacturer Overview

| Location | Hebei ,China |

| Year Established | 1958 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Southern Europ; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port |

| Export Percentage | 41%-50% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Papaer Grade NANO-Zinc Oxide

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- 6000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches