Packing Machinary for cartons

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

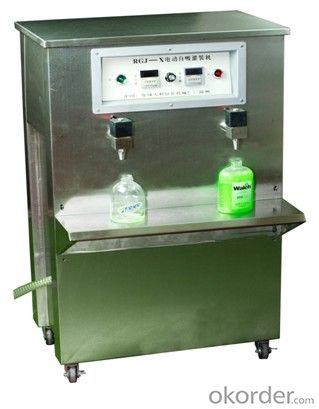

| Type: | Filling Machine | Condition: | New | Application: | Food,Medical,Chemical |

| Packaging Type: | Cartons,Cans | Packaging Material: | Plastic,Metal,Glass,Wood | Automatic Grade: | Automatic |

| Driven Type: | Pneumatic | Voltage: | 3p 380/220v 50/60hz | Power: | 5kw |

| | | | | | |

| Dimension(L*W*H): | 2800*1400*2400 | Weight: | 700kgs | Certification: | ce |

| After-sales Service Provided: | Engineers available to service machinery overseas | Usage: | Outer | use: | General |

| style: | Packing Machine |

Packaging & Delivery

| Packaging Detail: | Seaworthy plywood case |

| Delivery Detail: | 40Days |

Introduction:

This machine is capable of dispensing powder into roundshaped rigid container at line speeds up to 100 bpm ,Multistages filling integrated with check weighing and reject system it provides precise weight control to save expensive product giveaway and featured with high speed and high accuracy.It is widely used in milk powder production line with good outcome and stable performacne.

Specifications:

| | |

Dosing mode | Multi-Stage Filling with inline check weigher and reject system |

Direction | Left to right |

Filling Capacity | 100 - 2000g(With different set of auger and funnel) |

Container Size Range | Φ60-135mm; H 60-260mm |

Fill Accuracy | 100-500g, ≤±1g; ≥500g,≤±2g(Depending upon the density of material) |

Hopper Volume | Big (85L) Small(60L) |

Filling Output | Up to 90-100cans/min(900g) and 110-120 cans/min(400g) |

Power Requirement | 3P AC208-415V 50/60HZ |

Power Supply | 5KW |

Dimensions | 2900mm(L)*1400mm(W)*2500(H) |

Gross Weight | 600KGS(Approx) |

Main Features:

1: Multi-stage filling integrated with inline check weigher and reject system: High

speed ,high accuracy.

2:All parts and assemblies coming in contact with powder are made of S.S.304 and easily

removable for maintenance changeover.

3:NO BOTTLE, NO FILL" System eliminates wastage of costly powder.

4:Conveyor driving is through High quality Gear motor with stable performance.

5: Filling controlled by servo system with adjustable speed and high accuracy outcome.

6: Single track bottle movement, reduces setting of supporting guide rails and

semi skilled person can also easily operate the machine.

7: Pneumatic bottle indexingsystem is connected with auger rotation,

which eliminates chances of bottle transfer before completion of filling operation.

8: No change parts are required for any change in bottle diameter in certain set

range.

- Q: The role of food packaging machinery

- (8) can promote the development of packaging machinery related industry is a comprehensive science which is related to many subjects, materials, process and equipment, electronics, electrical appliances, automatic control and other related disciplines, requires the simultaneous and coordinated development, the overall performance of any discipline problems will affect the packaging machinery. Therefore, the development of packaging machinery will effectively promote the progress of related disciplines. In addition, in order to meet the needs of high-speed packaging machinery packaging, the relevant front and rear processes are bound to adapt, and also promote the simultaneous development of related processes.Fig. 3 is a flow chart of liquid filling. With empty bottles of boxes stacked on pallets, by the conveyor belt to depalletizers, will remove the tray one by one, the box with the conveyor belt to the machine, remove the empty bottles from the box, empty by the conveying belt to the washing machine, after cleaning, and transported to the packing machine next to filled with beverage bottles into them. The empty bottles removed from the unloading machine are sent into the bottle washing machine by another conveyor belt for disinfection and cleaning. They are tested by the bottle inspection machine and conform to the cleaning standard and then enter the filling machine and capping machine. The beverage is bottled from a filling machine. Packed beverage bottle capping machine with the sealed and transported to the labeling machine labeling, (see pictures) with various beverage bottle filling line of the process is similar. But because of the different nature of beverage, the filling machine and capping machine are also different.

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- You can consider the promotion above the industry website.Plus, you're the packaging machine for candy and cookies, and of course it's the maker of candy and cookies.

- Q: What are the main functions of packaging machinery?

- In order to meet the requirements of many customers, our company has learned from all aspects of the role of packaging machinery and equipment, so that we need customers for reference

- Q: What kind of reducer is commonly used in packaging machinery?

- There are many kinds of packing equipment, such as food packing, filling, quantitative packing, back channel packing and so on

- Q: What is the name of the paper used in packing machine parts and yellow?

- Vapor phase rust proof paper is coated with vapor phase corrosion inhibitor on the base of antirust base paper (surface like kraft paper, but with chloride ion and sulfate ion limit requirement)

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- If these are good, and then talk about the price, always a penny goods, this side, quick packaging machine is not bad,

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- This is really not sure, it can be said that any group, as long as the packaging products are required to use packaging machinery. Most of the products are now in need of packing. So it can be said that any group.

- Q: What is the working principle of the pillow packing machine?

- The sealing form - bag two sealing, a middle sealing surface,

- Q: What does the mechanical equipment include?

- Hydraulic lifting track machineHydraulic tamping machine, rail sawing machine, rail machine

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- 5009.101 determination of antimony in polyester resins and their moulding products for food containers and packaging materialsGB 13113 hygienic standard for polyethylene terephthalate moulding articles for food containers and packaging materials

Send your message to us

Packing Machinary for cartons

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords