Outdoor stairs decking FROM China with CE passed

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

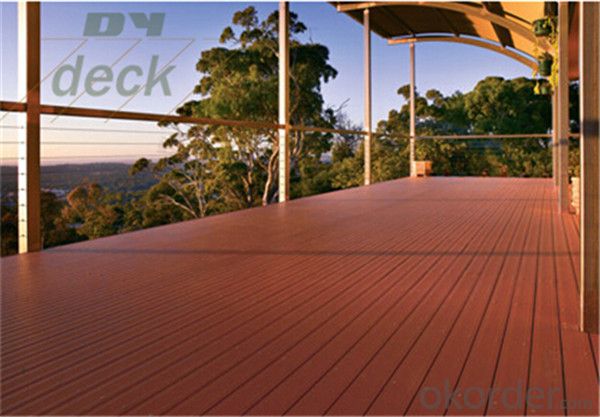

一. Structure of Outdoor stairs decking

Item | Outdoor stairs decking -- China 10 Years Experience Composite Decking Suppliers |

Material | Wood Plastic Composite |

Color | Cedar, Coffee, Brown, Black, Dark gray, Light gray, Red wood, Red pine, Yellow, or adjusted to customer's requirement |

Surface | Groove, Wood Grain, Sanding |

Length | 2.2m/pc, 2.9m/pc, 5.4m/pc |

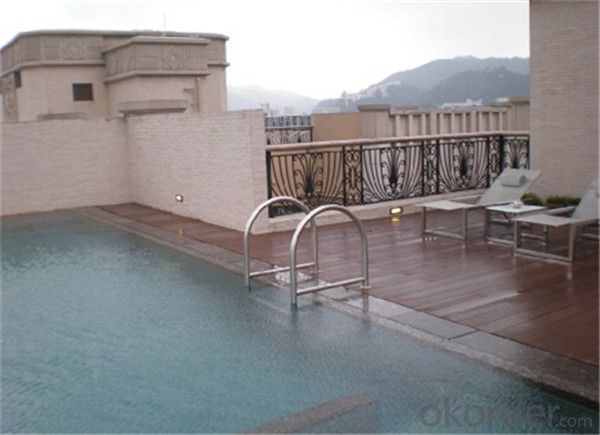

Application | Terrace, Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground |

Packing | PE Film + WPC Pallet (length of 0-2.2m) or Wood Pallet (length>2.2m) optional |

Certificate: | CE, SGS, CMTL |

二.Main Features of Outdoor stairs decking

WPC/PVC outdoor decking, indoor decking, soft pvc decking, wall panel, handrail, arbor,stand colum, tray panel, keel, grilling, connection, horny line, great wall panel, buckle ceiling, square pillar, door frame, door line, door mullion, PS foam profile, Accessoreis

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

三.Outdoor stairs decking

四.Outdoor stairs decking Specification

Name | Outdoor stairs decking |

Size | W*H=145*30 mm |

Length | 2200mm, 2800mm, 4000mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

五.FAQ of Outdoor stairs decking

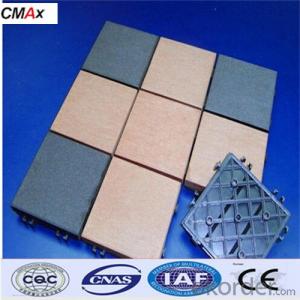

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: What's the function of the plastic film under the wood floor?

- Prevent moisture and moisture, so as not to the floor because of water seepage to the deformation of the wooden floor.

- Q: How about the plastic floor?

- 4 comfortable, there are a variety of optional thickness, coefficient of resilience.5 price coverage.6 if you want to change, as long as the above and then paste a layer can be.

- Q: Water general plastic floor glue harmful to the human body

- Will affect people's health. If you have laid the domestic PVC roll floor, there is a serious odor, it is recommended that you often open the window ventilation, maintaining indoor polite circulation, reduce indoor pollution.

- Q: How many yuan per square meter of plastic floor

- Customer: why is your price so cheap? Shanghai and the United States to answer: factory direct sales! 3, the customer asked: your home a few years ago? Shanghai, Shanghai and the United States replied: plastic floor 50 yuan per square shelf life of 6 years, the price of $180 per square shelf for 15 years! Please understand Shanghai Hu Mei plastic floor for the sports ground facilities, good floor to prevent injuries, foot comfort

- Q: With this plastic floor mat bed can not? Will not have any impact on people

- Good insulation, but not breathable, it is best not to use directly on the bed! It's better to use a sponge mattress!

- Q: Self adhesive stone plastic PVC floor leather will not stick it

- The harmful substances of floor leather products mainly refers to the content of heavy metals and the amount of volatile substances. Heavy metals are mainly cadmium, lead, and so on, the limited volatile mainly refers to alcohol, toluene and other substances. Some of the smaller, do not pay attention to the quality of the products produced by enterprises mostly contain these substances, and the content exceeded. So in the selection of the product, should choose to buy large manufacturers, brand-name products. First of all, the need to lay the floor of the room to clean up, uneven terrain with cement scraping once, to keep the ground level. Second, the correct calculation of the living room area and then spread the floor tile floor on the ground, static 30 ~ 60 minutes, to be flat after the formation of the roll floor splicing. In the splicing must use adhesive bonding, or a long time easy to roll edge, thus affecting its life.

- Q: What is the difference between PVC plastic floor and graphite plastic floor

- PVC anti-static floor is plastic floor, mainly composed of polyethylene material, the PVC floor can be made of two kinds, one is homogeneous, is from the bottom to the pattern material is the same, the floor if the surface being burned or cut off, can use the grinder to waxing is new as there is a composite type, is the top layer is a transparent layer of pure PVC (wear resistance of PVC is very good) and then add on the printing layer and the foam layer, so the fire performance of the composite material do not seem to matter and information. PVC floor is widely used in all aspects of home and business because of its rich and varied colors.

- Q: Plastic floor joints how to deal with?

- Hot melt welding: when the plastic floor laying is completed, the use of plastic floor materials and the corresponding special electrode, according to the type of material to adjust the temperature of hot welding.

- Q: Free glue self-adhesive stone PVC floor leather plastic floor glue floor toxic

- As long as the material is PVC plastic floor, basically are environmentally friendly, more plastic factory is mioT answer for you

- Q: Plastic floor can be spread in the bathroom

- Buy plastic floor is a choice of material, how to install the plastic floor, plastic floor price, how much money Shanghai plastic flooring, plastic flooring, plastic flooring manufacturers, professional plastic floor, Fuzhou plastic floor, plastic floor thickness, plastic floor of environmental protection, Hangzhou plastic floor, plastic floor floor size, plastic floor specifications, plastic floor number money,

Send your message to us

Outdoor stairs decking FROM China with CE passed

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords