Glass Wool One-Layer Real Al Foil Bubble Fire Retardant Insulations

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. One-layer Real Al Foil Bubble Fire Retardant Insulation Description:

Reflective insulation material consists of one or two layers bubble or foam that are sandwiched between layers of 99.9% pure aluminum radiant barrier foil . This style can be used in a variety of applications because of its thin, lightweight properties. The bubble layers creates Maximum R value and Vapor barrier , the reflective foil on both sides allow it to reflect 97% of radiant heat away from a structure on the outside and back into a structure from the insides. This is why it works effectively in both hot and cold climates

2.Main Features of the One-layer Real Al Foil Bubble Fire Retardant Insulation:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

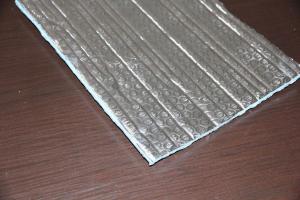

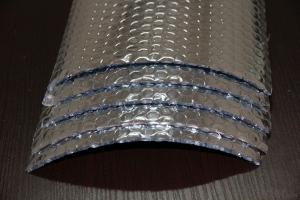

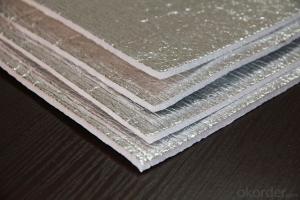

3. One-layer Real Al Foil Bubble Fire Retardant Insulation Images:

4. One-layer Real Al Foil Bubble Fire Retardant Insulation Specification

PROPERTIES Test Data

Thinkness 3.5MM

Weight 256G/M2

Emissivity 0.03-0.04COEF.

Thermal conductivity 0.034W/MO

Apparent Density 120KG/M3

Reflectivity 96-97%

Water Vapour Transmission 0.013G/M2KPA

Corrosion Doesn't generate

Tensile strenght(MD) 16.98Mpa

Tensile strenght(TD) 16.5Mpa

AL+bubble +AL

AL +bubble /bubble +AL

AL+Bubble+ Foam+Bubble+AL

AL+Bubble+PE

AL+EPE +BUBBLE+AL

AL+XPE+Bubble +AL

Note : AL refer to Aluminum Foil,the structure and the surface color of AL can be changed as customer’s requirement

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of Fire Retandent AL Bubble Foam Insulation and is one of the large-scale professional investment Fire Retandent AL Bubble Foam Insulation bases in China. Annually more than 1000 containers of Fire Retandent AL Bubble Foam Insulation are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Does rock wool refer to the glass wool?

- Rock wool is not glass wool, rock wool's main material is basalt, glass wool material is glass.

- Q: Can glass wool be used for external wall insulation?

- Yes, of course, but the thermal insulation effect of glass wool is generally not very good, suggest using XPS board or EPS boards.

- Q: What are the hazards of glass wool to body?

- Non-environmentally friendly materials, the Olympic venues banned: In view of the glass wool is not environmental factors, the State Ministry of Construction and the Beijing Municipal Health Bureau issued the relevant provisions

- Q: who knows the construction technology of glass?wool?board?

- Construction Technology of glass wool board is very refined, and it is more professional. apply one layer of dry laid asphalt → → wooden keel installation→ → install gypsum board glass wool blankets → Paste a layer of glass fiber cloth → → mounted on an aluminum mesh → → fixation of aluminum mesh. I think it is very commendable technique.

- Q: Is the microporous aluminum silicate coated with aluminum wool?

- Aluminum foil with pure embossed aluminum foil and aluminum foil

- Q: The main classification and difference of glass wool

- The main classification and difference of glass wool

- Q: Are foam glass and glass wool the same?

- Different.

- Q: Is centrifugal glass wool board suitable for home use?

- A large number of people think that glass wool boards are harmful and that it will cause itch when contacting with the skin. And the effect is not obvious used in the surface, so it is generally used in the wall sandwich. They are harmless for wool boards have been checked, and only those which have passed the national inspection are allowed to be sold for home use. But do not use it in the surface as it is fiber products.

- Q: What are the functions of the thermal insulation glass wool board?

- Glass wool that is produced by advanced centrifugal blowing method is of soft texture, thin fiber, good elasticity and fireproof property(reinforced aluminum foil can be used as veneer), providing an ideal thermal insulation and sound absorption material for the construction of steel structure.The product is of good acoustic insulation effect, low cost, short construction period and elegant appearance. Besides, it is non-toxic, not irritating to the skin and can ensure the safety of construction workers.

- Q: What are the industry standards of glass wool and its products?

- Conventions of Quality Management of Enterprises producing Glass Wool and its Products by National Building Materials Bureau Chapter I General Provisions 1. In order to strengthen the quality management of enterprises producing glass wool and its products, and constantly improve quality of products, the cnventions are formulate in accordance to "Product Quality Law of People's Republic of China" and the relevant regulations of the State Council. Associated regulations: 2. Enterprise leaders and workers should continually enhance the awareness of quality and adhere to the development of quality and efficiency, firmly establish the concept of "quality first" and "customer service" and continue to strengthen quality control in the production process to ensure that raw materials, fuel, semi-finished products, finished products and packaging and storage are up to technical standards. Article 2 Enterprises should set advanced, rational and scientific quality principles and objectives. Legal representatives should be in full charge of products quality, and the department of quality management should take full responsibility in management. Distribution of income within the enterprise should be made to link with the quality of work and products, and implement veto of quality. Article 4 Enterprises must strictly enforce product standards, establish and improve the quality system, and implement quality functions combined with the reality of the enterprises in accordance with GB / T19000 a ISO9000 "quality management and quality assurance" series of standards and the provisions of this Regulation. Capable enterprises should draw up "quality Manual", and seriously implement it.

Send your message to us

Glass Wool One-Layer Real Al Foil Bubble Fire Retardant Insulations

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords