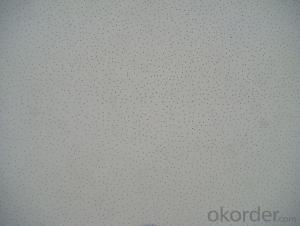

Oem Mineral Fiber Ceiling Board - Good Quality MS02

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plasterboard is made of high-grade environmental protective gypsum raw material,

no harming to human body, and it has some performances: (such as environmental protection,

fire-proof, moisture-proof, light and high intensity).

Plasterboard is easy to install, and its decoration effect is good. Its special indoor temperature

adjustment function can provide a comfortable living environment. It is the first choice to interior decoration.

Product Applications:

1.Thermal insulation

2.Fire-resistant performance for fire-proof plasterboard

3.Water-resistant performance for water-proof plasterboard

4.Easy installation (it can be easily sawed,planed,holed and sticked)

5.Special respiratory function (it has a great mass of ting holes

Product Advantages:

1.Thermal insulation

2.Fire-resistant performance for fire-proof plasterboard

3.Water-resistant performance for water-proof plasterboard

4.Easy installation (it can be easily sawed,planed,holed and sticked)

5.Special respiratory function (it has a great mass of ting holes and its function of moisture-adsorbing and moisture-dismissing)

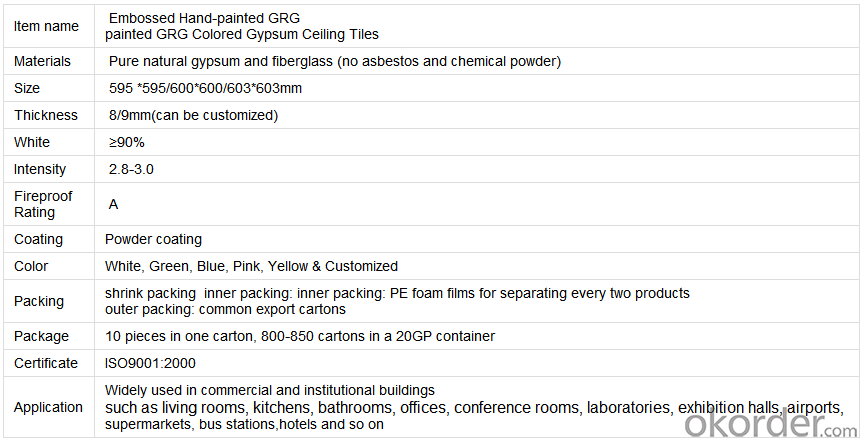

Main Product Features:

Material: Gypsum Board, non asbestos, sulfate free

Surface: High quality PVC/Vinyl

Backside: High quality aluminized PET foil

Edges: Square

Weight /cbm: 780kgs/m3

Tolerance: Length: ± 1.0mm, Width: ± 1.0mm,

Thickness: ± 0.5mm

NRC: 0.1 - 0.3

Light reflection: 0.75

Standards: Gypsum boards are manufactured according to EN-520, ASTM C1396, E84 and E96

Humidity resistance: up to 95% relative

Product Specifications:

FAQ:

1. What kind of certificate do you have?

ISO9001, ISO14001, CE, SONCAP, VOI(CO), CARB, FSC, CE

2. What color can you produce?

You can choose the design you want

3. How about the delivery time?

20-25 days after receiving prepayment or L/C

For the samples, it will be prepared ASAP.

4. What's the MOQ and Payment Terms?

Minimum Ordering Quantity: 2X20ft Container

Payment Terms: T/T or L/C at sight

Images:

- Q: Small car dismantling plate is not illegal conversion

- Great Wall C20R 2017 paragraph 1.5L manual luxury% D% A [most satisfied]% D% A this price can buy such a car, really worth, cost-effective. Site high, through the good, look better look, a few friends are envious of my purchase of this model.

- Q: What are the new interior wall decoration materials?

- Now more new type of interior wall decoration materials are mainly imitation marble decorative panels, ice plate, 3D jade carving background wall decorative panels, relief plates, integrated wall panels, wall panels and other materials. These products compared with the traditional wall decoration materials, the protection of the wall better, waterproof fire, construction is simple and quick, and more healthy and environmentally friendly, free of formaldehyde, benzene and other harmful substances. But ultimately depends on your own needs, sales, then pay attention to the market, their own home to use the words to see the overall decoration style and functional requirements, such as if used in the bathroom, you need to use Chang Cheong Bing plate, because the ice plate anti- , Will not be affected by high humidity environment.

- Q: Marble uv board decorative plate is not science and technology stone

- Belong to the board like marble

- Q: Uv stone plate sticky method, what glue

- Water transfer joints, and then fill the joints in the two UV board 45 degrees angle intersection, first filled, and then the vertical angle of wood from the 45-degree angle at the intersection of gently across, so that the intersection of beautiful

- Q: Indoor wall decoration board like wood flooring is what kind of material

- Generally is the wooden floor, the wall is best to have a small keel or a large core board used to fix the wood floor. Can not be used with mosquito nail guns. Hand fee of about 20 yuan a square meter

- Q: Wall decoration board

- With the coating in the polishing surface spray 2 to 5 times; the coated plate after drying or natural drying; on the dry plate with high weathering resin coating 1 to 2 times. The production process is simple, unique, the production of decorative plate light, smooth and delicate surface, color and diverse, beautiful high-grade, low cost, good sound insulation effect, corrosion resistance, good moisture resistance.

- Q: Installation of external wall insulation decorative panels need to pay attention to what the details of the problem

- According to the design of the design of the split map to determine the horizontal direction of the baseline, and according to the drawings and the size of the template to determine the vertical control line, the baseline required closed loop to determine the horizontal rubber band.

- Q: Transparency and acrylic panels are almost decorative boards but the plates are lighter than acrylic and can you use slices with plane trims?

- Acrylic board is commonly known as plexiglass plate (PMMA)

- Q: There is no understanding of wood fiber integrated wall decorative plate technology, and ask the big god to help

- Do you mean high fiber board, the board surface can be carved patterns, used in the surface decoration.

- Q: Does the decorative board need to paint a layer of paint? Decorative board wall construction process is how?

- Construction technology measures: 5.1 find and play line: wood wall panels should be installed according to the design Atlas requirements, in advance to find a good elevation, flat position, vertical size of the elastic line. 5.2 Check the embedded parts and holes: After the bumper line to check whether the embedded parts, wood bricks or wooden wedge meet the design requirements, spacing spacing size, position to meet the requirements of the lapel keel; measuring doors and windows and the location of the size of the vertical And design requirements are consistent. 5.3 shop, coated with moisture-proof layer: the design of moisture-proof requirements when the wooden wall, wood keel installation must find a square, looking straight, skeleton and wood between the gap should be pad mats, each brick at least 2 nails nail, And then put the keel should be set aside when the board thickness. Wood keel and wall contact surface to be anti-corrosion treatment, the remaining three sides of not less than three times the treatment of fire paint. 5.4 Lining installation: After the installation of the keel to check the qualified installation of 15mm thick woodworking board to do lining, requiring liner nail firm, nail fixed spacing control in 200mm or so, the back brush fire paint, splicing board should be reserved between the 5mm Around the expansion of the gap, to ensure that the amount of expansion and contraction of temperature.

Send your message to us

Oem Mineral Fiber Ceiling Board - Good Quality MS02

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords