Occasional Office Sofa with Artistic Pattern

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Occasional Office Sofa with Artistic Pattern Description

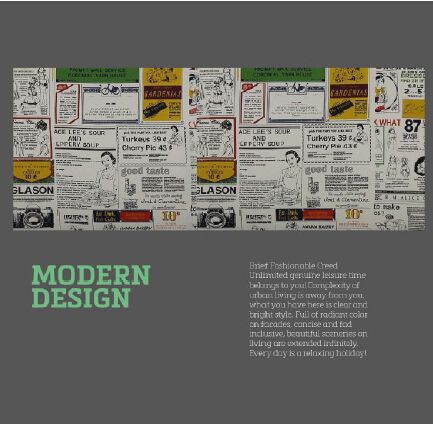

This occasional office sofa with artistic design features a leisure and modern style. This occasional sofa crosses the line between business and art, equally at office at creative room at home. The design brings creative idea to the people working in a busy day.

Occasional Office Sofa with Artistic Pattern Characteristics

· Leisure and free style

· Artistic pattern design

· Brushed steel legs

Occasional Office Sofa with Artistic Pattern Image

Occasional Office Sofa with Artistic Pattern Specification

Item | Content |

Name | Furniture |

Item Type | Office sofa |

Item Description | Occasional office sofa |

Size | 1 seater: 82*86*76 3 seater: 182*86*76 |

Color | All colors/pattern are available |

Upholster Material | Fabric |

Sofa Frame | Metal Frame |

MOQ | 20 sets |

Production Capacity | 5000 sets per months |

Packaging | Carton |

FAQ

Do you accept OEM/ODM?

Products can be made according to your requirements. ODM/OEM is welcomed.

What is the warranty?

We offer 2-5 years warranty replacement against manufacturer defect.

What is your advantage?

We have strict quality control department to ensure all the goods to be right & correct delivery to customers.

All of our products are environmentally friendly meet the international standard.

- Q: How do you make the plywood process?

- Plywood is one of the commonly used furniture materials. It is a kind of artificial board. A set of veneers usually glued together in a direction perpendicular to the direction of the adjacent layers of wood. Usually the table plate and the inner plate are symmetrically arranged on both sides of the central layer or the core of the plate. A single slab made of glued sheets that are Criss crossed in the direction of wood grain. The number of layers is generally odd, and even a few are even. The physical and mechanical properties of the vertical and horizontal directions are less different. There are three commonly used plywood, plywood etc.. Plywood can improve wood utilization, and it is a main way to save wood. They can also be used in aircraft, ships, trains, automobiles, buildings and packing boxes.

- Q: What is plywood?

- The symmetrical structure can reduce the variation of the plate, and the grain direction of the two table plates is consistent. The veneer is coated with a high strength adhesive and pressed at a certain temperature and pressure.

- Q: Plywood surface bonding strength is very important, as a leading brand of plywood in China, how about this aspect?

- The plywood surface bonding strength more than 0.4MPa provisions of the state. The bond strength refers to the special adhesive for special steel clip (steel head bottom surface area of 400 mm2 2*2 cm) bottom surface adhesion in the specimen along the central, around the cut card head decoration layer board, cutting depth to the substrate surface, and then completely after the cement (1 hours later), then pull straight up, pull Newton said.

- Q: How are the plywood made?

- Principle of odd number layer: because the structure of plywood is adjacent layer, the fiber direction of single board is perpendicular to each other, and must accord with symmetry principle, so its total layer number must be odd number. Such as: three laminates, five laminates, seven laminates and so on. When the odd ply plywood is bent, the maximum horizontal shear stress acts on the central veneer to make it have greater strength. Even when the plywood is bent, the maximum horizontal shear stress acts on the adhesive layer, not on the veneer. It can destroy the adhesive layer and reduce the strength of plywood.

- Q: What are synthetic plates, multilayer plates, plywood?

- The multilayer board is composed of logs into veneer or wood sliced veneer, with adhesive glued into three or more layers of sheet material, usually with odd veneer, and the fiber direction of adjacent plates perpendicular to each other and gluing.

- Q: Decorate each floor, want to use bamboo plywood, just do not know to have poison?

- Bamboo plywood is pre pressed with glue, and the main component of gum is made of formaldehyde, so there is formaldehyde molecule in bamboo plywood, so it is polluted with formaldehyde with bamboo plywood. But now the market has developed a kind of governance decoration pollution, more environmentally friendly, fast and effective products, called biological clear aldehyde enzyme, you can try it with.

- Q: Pressing process of plywood

- The plywood is logs into veneer or by wood sliced veneer, with adhesive glued into three or more layers of sheet material, usually with odd veneer, and the fiber direction of adjacent plates perpendicular to each other and gluing.

- Q: What are the differences between LVL, LVB, plywood and plywood? Is it divided by the use of it, or is it just a different name?!

- Name is not the same, the structure of the plate is not the same, the pressure and the degree of seed is not the same.

- Q: What is an offset press? And what are the machines for printing paper?

- Offset lithography is a very simple, means of speaking that is offset rubber (Pib) will plate transfer to the substrate of printing, it is also the existence of Pib, named after the printing mode. The blanket has played an irreplaceable role in the printing process, such as: it can make up for a good substrate surface is not flat, so that the full transfer of ink, it can reduce the plate of water (see water in the role in printing) to the substrate transfer etc.. The above is only a general concept, we usually say that now the offset may be more narrow in scope, namely the three roller (printing, lithographic printing, embossing blanket), in the south of our country to the printing mode called offset printing.

- Q: Desulfurization absorption tower anticorrosive lining glue, specifications have stipulated, rubber board need sampling?

- In addition to the quality inspection of the appearance of the rubber plate, rubber plate (after curing) to physicochemical properties were tested, the test contents are: tensile strength, tensile strength, stretching rate, volume weight, hardness and bonding strength of plywood and the matrix, the above indexes must be rubber lining construction quality can be guaranteed, the above index must be qualified to ensure the final quality of the rubber lining construction. The adhesive properties also play an important role in the final quality of the anticorrosive lining. The rational properties of the general rubber sheet and mortar are tested in the manufacturer. The inspection of rubber plate and glue for rubber lining equipment is an essential step, and must pay attention to it!

Send your message to us

Occasional Office Sofa with Artistic Pattern

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords