NUT COKE of 20 - 50mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

CNBM MET COKE of NUT COKE of 20 - 50mm

Under the condition of strong acid, can be accessed by Fe3 + SnCl2 reduction of Fe2 +.Sn2 + will be after the completion of Fe3 + reduction, methyl orange can be Sn2 + faded back into hydrogenated methyl orange, and methyl orange can indicate Fe3 + reduction destination.Sn2 + also can continue to make hydrogenation of methyl orange reduction of N, N - dimethyl para-phenylene diamine and sodium aminobenzene sulfonic acid.Iron ore is the international commodities, strategic materials, belongs to the economy and the like.

The intended use of CNBM MET COKE of NUT COKE of 20 - 50mm

Our CNBM MET COKE of NUT COKE of 20 - 50mm are ideal for:

· Power plant

· Steel mills

The advantages of CNBM MET COKE of NUT COKE of 20 - 50mm

Not only are OKorder's CNBM MET COKE of NUT COKE of 20 - 50mm of the highest quality and reliability, we are able to quickly ship orders within 20 days of receiving a deposit or original L/C.

Main features of CNBM MET COKE of NUT COKE of 20 - 50mm

l Unique Frame Design For Easy Installation

l High energy conversion efficiency

l Reliable performance

FAQ:

Q1: Where is your warehouse?

A: Tianjin

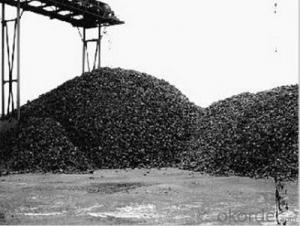

Metallurgical Coke of Coke NUT COKE of 20 - 50mm Images:

Specifications:

Parameters | Guarantee | Rejection |

Total Moisture (As received basis) | 5% max | |

Ash (dry basis) | 12.5% max | > 13.5% |

Volatile Matter (dry basis) | 1.5% max | > 1.8% |

Sulphur (dry basis) | 0.65% max | > 0.75% |

Phosphorus (dry basis) | 0.035% max | > 0.045% |

M10 | 7% max | > 9% |

M40 | 84% min | <82% |

CSR | 64% min | <62% |

CRI | 26% max | > 28% |

Size 30-90 mm | 90% min | |

+90 mm | 5% max | > 8% |

-30mm | 5% max | > 8% |

At present, the main customers are NOBLEGROUP, IMR and so on. Our main overseas markets are Japan, India, Brazil, Iran,Vietnam, and so on.Let me know your demands then I can check availability.

- Q: Coke is how to make it? What is the use?

- Coke production has prepared the material into the coal charging car from coal tower, were sent to the furnace chamber. The gas produced by the dry distillation is sent to the chemical product recovery workshop for processing. After a coking period (from charging to pushing the required time is generally 14 to 18 hours, depending on the carbonization chamber and the width), a pusher will mature by refining coke coke machine into the coke car; coke quenching, coke is discharged into the cold coke; then screening and storage (Figure 4).The coking plant is generally composed of two coke ovens. The two coke ovens are arranged on the same central line, and a coal tower is arranged in the middle. A furnace with coke oven machinery -- corresponding charging car and coke machine, machine coke, coke quenching car and motor vehicle; also equipped with a set of facilities including coke quenching, coke quenching tower, coke quenching pump, coke powder and coke powder sedimentation tank grab, arranged in the end furnace group. The center of the coke quenching tower is not less than 40 meters from the center of the carbonization chamber. If dry coke quenching, coke oven station. The coking plant is also equipped with the necessary piping and reversing system.

- Q: What is the reasonable ratio of coal to coke

- According to the proportion of each unit type, different operation, different existing coal and different coke quality requirements are different and so on, can be said to suggest that the landlord can look at the altar of the myriads of changes, in some aspects of the coal blending, grasp some general principles, and then develop the proportion according to the actual situation.

- Q: Ask: coking coke tower tower and what is the relationship?If you can give a working principle to explain what is better!Coking tower in oil coking plant

- Coking plant coal tower, primary cooling tower, cooling tower, etc.. The coal tower is used to store coal for coke oven. The cooling tower is used to cool the gas and cooling tower cooling water.

- Q: What are the indicators of first grade coke and the two grade coke?

- Two level 12.01-13.50 0.61-0.80 not less than 76 not greater than 9 not greater than 1.9Three level 13.51-15.00 0.81-1.00 not less than 72 not greater than 10 not greater than 1.9

- Q: Types of coke and use of coke

- The vertical furnace processing of low metamorphic coal production of calcium carbide, ferroalloy, coke, chemical fertilizer production and ultra high power electrode, aerospace and medical high technology and high value-added products such as carbon needle coke the world's most complete and unique characteristics of the Chinese coking industrial system.

- Q: How to distinguish the level of coke. What is metallurgical coke

- Coke type: coke is usually divided by use of metallurgical coke (including blast furnace coke, coke and iron alloy coke etc.), coke and calcium carbide with coke gasification

- Q: I don't understand. With coke, then the rest of the coke, they are selling it?

- According to the use of coal can be divided into: injection coal, coal, coal coking coal can be divided into: lean coal, coking coal, gas coal, fat coal, lignite in five categories. Coking coal is used to refine coke. The power plant's coal coal power coal can also be said that under normal circumstances, can not be used for coking coal can be used to make electricity.

- Q: The chemical composition of coke m10.m25 refers to?

- M10 refers to the wear resistance of coke, M25 refers to the crushing strength is the mechanical strength. Mainly the cold strength of coke. Coke is also the most important indicator is the hot state, CRI thermal reaction and CSR reaction intensity. In blast furnace production, both cold and thermal strength are important.

- Q: Why in the blast furnace ironmaking with coke instead of charcoal why coke can produce heat to improve the heat of the furnace how to produceWhy in the blast furnace ironmaking with coke instead of charcoal why coke can produce heat to improve the heat of the furnace how to produce

- The role of coke in the blast furnace: 1 reducing agent 2 heating agent 3 skeleton role. Combined with the effect of coke in the blast furnace can know compared with coke instead of charcoal. The coke oven gas is produced high calorific value of fuel, and is an important raw material for organic synthesis industry.

- Q: What is the difference between coke and coking coal

- Metallurgical coke is coke, coke, iron alloy coke and non-ferrous metal smelting coke for metallurgical coke collectively. More than 90% are used in blast furnace, the furnace coke often called metallurgical coke. Metallurgical coke quality standard Chinese formulation (GB/T1996-94) is the blast furnace quality standards.Gasification coke is a kind of coke, which is specially used in the production of gas. It is mainly used in the fixed bed coal gas producer with solid slag discharging. It is used as the raw material to produce CO and H2 gas

Send your message to us

NUT COKE of 20 - 50mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords