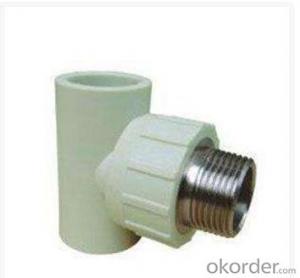

1 Inch Black Plastic Water Pipe Fittings - New PPR Three Tee Fittings for Industrial Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview:

1.It is used in industrial fields, agriculture and irrigation.

2.Beauty appearance.

3.Thermal insulation and energy saving.

4.Easy installation

5.excellent heat resistance and pressure resistance

6.affordable price

Why choose us?

(1) Professional factory: We are manufacturer, specializing in manufacturing multilayer PP-R, PE pipe and PP-R, PE pipe fittings for more than13 years, our price is competitive with high quality. And we can delivery product in quick way.

(2) Sample: We can send samples out in 3 days, but the express charge usually paid by your side, but the fee will be rebound when we have formal order.

(3) Rapid response to your needs: We will be answer within 24 hours. Welcome to contact with us if you have any problems. We are looking to cooperating with you.

(4) We hope we can establish long-term and mutual benefit business relation with you. If you have any problem, please kindly feel free to contact me. I will try the best to help you!

Product Descrition

Product name | Size | Weight | Pack |

Equal tee | (Gram/m) | (m/pack) | |

T16 | 12.5 | 1300 | |

T20 | 19.4 | 800 | |

T25 | 30.5 | 450 | |

T32 | 48.2 | 260 | |

T40 | 90.8 | 150 | |

T50 | 142.5 | 106 | |

T63 | 275.3 | 54 | |

T75 | 515.0 | 30 | |

T90 | 712.0 | 18 | |

T110 | 1082.0 | 12 | |

T125 | 1544.0 | 8 | |

T160 | 2531.0 | 4 |

Product Show

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: What tools and methods are needed for the installation of plastic hoses and steel tubes?

- Because of the linear expansion of PVC - U drainage pipe, the temperature expansion is larger. In the installation of drainage risers. To install expansion joints, but how to install, and what part of the installation, the construction unit is notVery clear. At the same time in the construction of cross branch often is not properly installed or not installed bellows expansion joint, and in accordance with the specifications, drainage cross branch, stem straight pipe, ventilation pipe, circular ventilation tube apparatus and ventilation pipe on the confluence confluence no greater than 2 m, should be set expansion joints, and horizontal drainage the branch should set up special expansion joint. And the maximum spacing of retractable joints shall not exceed 4 M.

- Q: Spiral drain pipe fittings are not special pipe fittings

- Because the product of the tube holes in the trough, and elongated, effectively overcomes the planar circular hole is easy to block defects affect product drainage effect, according to the requirements of different drainage tube hole size is 10mm * 1MM-30MM * 3mm, and at 360 degrees, 270 degrees, 180 degrees, 90 degrees. Within the scope of the uniform distribution, widely used in highway, railway subgrade, subway engineering, waste landfill, tunnel, greening slope protection drainage belt, athletic field and high water content caused by agriculture, gardening, and underground irrigation and drainage system. It has become the three main products of civil engineering construction (water seepage, drainage) with soft permeable pipe and plastic blind ditch. According to the drainage pressure of municipal drainage network, double arm bellows and straight wall pipe can be used. The pressure of the straight wall pipe is stronger, and it can be used in the special pipe of large-scale drainage and sewage pipe network.

- Q: Can plastic pipe fittings be used for gas lines?

- No, plastic pipe fittings should not be used for gas lines.

- Q: Are plastic pipe fittings resistant to chemicals?

- Yes, plastic pipe fittings are generally resistant to a wide range of chemicals. They are designed to withstand exposure to various substances and maintain their integrity over time, making them suitable for use in many different applications where chemical resistance is required.

- Q: Can plastic pipe fittings be used in chemical processing systems?

- Yes, plastic pipe fittings can be used in chemical processing systems. Plastic materials such as PVC, CPVC, and polypropylene are often chosen for their chemical resistance, durability, and cost-effectiveness. However, it is important to select the appropriate plastic material and ensure compatibility with the specific chemicals being processed to ensure safe and reliable performance.

- Q: What is the difference between plastic pipe fittings and hot melt plastic water supply pipe fittings?

- PSP is the abbreviation of steel plastic composite pressure pipe, P is PE or PPR, PERT and other materials should be the initial letter, S steel English letter referred to, as the name suggests PSP is sandwiched between two layers of plastic steel, with the aim of internal and external corrosion types, such products generally have high water to melt connection pipeline, inside and outside the plastic pipe with the use of fire, underground pipeline steel mesh skeleton.

- Q: Can plastic pipe fittings be used in storm drain systems?

- Yes, plastic pipe fittings can be used in storm drain systems. They are commonly used due to their durability, corrosion resistance, and affordability. Plastic fittings are available in various sizes and configurations, making them suitable for different storm drain system requirements.

- Q: Can plastic pipe fittings be used in swimming pool systems?

- Yes, plastic pipe fittings can be used in swimming pool systems. They are commonly used due to their durability, resistance to corrosion, and affordability. However, it is important to ensure that the plastic fittings chosen are compatible with the specific chemicals and temperatures involved in the swimming pool system to ensure their long-term performance and safety.

- Q: Are plastic pipe fittings suitable for use in marine environments?

- No, plastic pipe fittings are generally not suitable for use in marine environments as they are prone to degradation and brittleness caused by exposure to saltwater, UV rays, and fluctuating temperatures. It is recommended to use corrosion-resistant materials like stainless steel or brass fittings in marine applications.

- Q: Can plastic pipe fittings be used for pharmaceutical manufacturing?

- No, plastic pipe fittings are typically not used for pharmaceutical manufacturing as they may not meet the strict quality and safety standards required in the industry. Stainless steel or other specialized materials are commonly used in pharmaceutical manufacturing to ensure product integrity and prevent contamination.

Send your message to us

1 Inch Black Plastic Water Pipe Fittings - New PPR Three Tee Fittings for Industrial Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords