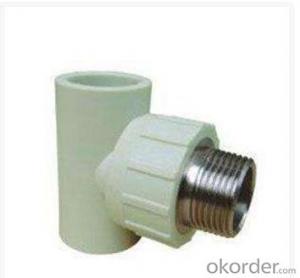

3/4" Plastic Water Pipe Fittings - New PPR Equal Tee Degree for Industrial Fields

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Material: Plastic

Technics: injection

Place of Origin: China (Mainland)

Connection: Welding

Head Code: round

Color: Green, White, Grey, Blue

Product Applications:

1.Distribution for cool and hot water

2.Duct for drinkable water system

3.Pipes for kinds of high-temperature and low-temperature heating system

4.Pipes for heating and coolling settings in solar energy system

5.Connecting pipe for air conditioner

Specifications

Standard: DIN8077/8078

Material: R200P from Korea

Size: DN20-63

Color: Green, White, Grey, Blue

Packaging Details

Packaging Details: PE bag + carton

Delivery Detail: 15 Days

Product Description

Pressure | Size(mm) | Pressure | Size(mm) |

PN1.25MPA | 20*2.0 |

PN1.6MPA | 20*2.3 |

25*2.3 | 25*2.8 | ||

32*2.9 | 32*3.6 | ||

40*3.7 | 40*4.5 | ||

50*4.6 | 50*5.6 | ||

63*5.8 | 63*7.1 | ||

75*6.8 | 75*8.4 | ||

90*8.2 | 90*10.1 | ||

110*10.0 | 110*12.3 |

Product Show

Advantanges

1, High Temperature Resistance: the maximum sustained working temperature is up to 70 Degrees Celsius, the maximum transient temperature is up to 95 Degrees Celsius.

2, Heat insulation and Saving Energy: low thermal conductivity which is only 1/1500 of brass pipe, and 1/250 of steel pipe.

Non-toxic: no heavy metal additives would not be covered with dirty or contaminated by bacterium.

3, Corrosion Resistant: resist chemical matters or electron chemical corrosion.

4, Lower Installation Costs: light weight and good hot-melt performance can reduce installation costs by as much as 50% over metal piping system.

5, Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume than metal pipes.

6, Long Life: more than 50 years under normal conditions.

7, Recycled and Environment-friendly.

- Q: Can plastic pipe fittings be used for underground cable protection?

- No, plastic pipe fittings are not suitable for underground cable protection. Underground cables require more durable and robust protection to withstand external forces and potential damage. Metal conduit or specialized cable protection systems are typically used for this purpose.

- Q: Are plastic pipe fittings resistant to rodents?

- Yes, plastic pipe fittings are generally resistant to rodents. The material used in plastic pipe fittings is not appealing to rodents, and they do not chew through it as they would with other materials like wood or metal. Therefore, plastic pipe fittings are a reliable option to prevent rodent infestations in plumbing systems.

- Q: Are plastic pipe fittings suitable for compressed gas applications?

- No, plastic pipe fittings are not suitable for compressed gas applications as they can become brittle and fail under high pressure, posing safety risks. Metal pipe fittings are better suited for these applications.

- Q: Are plastic pipe fittings resistant to solvents?

- Yes, plastic pipe fittings are generally resistant to solvents.

- Q: How do you choose the right size of plastic pipe fittings?

- To choose the right size of plastic pipe fittings, you need to consider the diameter and type of pipe you are using. Measure the outer diameter of the pipe and match it with the corresponding fitting size. Additionally, ensure that the fitting is compatible with the type of pipe material, whether it is PVC, CPVC, or another type. It is recommended to consult the manufacturer's specifications or seek professional advice to ensure the correct sizing and compatibility for your specific application.

- Q: What is the PVC pipe fitting?

- PVC (full name Polyvinylchlorid) for polyvinyl chloride, in addition to other ingredients to enhance its heat resistance, toughness, ductility and so on. The top layer of this surface film is lacquer, the main component is polyvinyl chloride, and the bottom layer is coated with adhesive. It is a very popular, popular and widely used synthetic material in the world today. Its global usage ranks second in various synthetic materials. According to statistics, only in 1995 a year, PVC production in Europe, there are about five million tons, while its consumption is five million and three hundred thousand tons. In Germany, PVC production and consumption averaged one million and four hundred thousand tons.

- Q: The difference between PP-R aluminum pipe and PP-R pure plastic pipe

- From the aging resistance performance, aluminum pipe stable molecular structure inner layer outer layer PE apart, allowed to join the enough anti light, anti oxygen stabilizer and does not affect the inner health water contact; PE molecular structure is stable, but the single structure is not conducive to the addition of stabilizer is easy to cause two pollution water pipe: PP-R tube containing tertiary carbon atom most unstable, vulnerable to light, oxygen and impurities and aging.

- Q: Are plastic pipe fittings easy to disassemble and reassemble?

- Yes, plastic pipe fittings are generally easy to disassemble and reassemble. They are designed with a simple push-fit or threaded connection system, allowing for easy removal and reinstallation without the need for specialized tools.

- Q: Are plastic pipe fittings resistant to hydrocarbons and oils?

- Yes, plastic pipe fittings are generally resistant to hydrocarbons and oils.

- Q: Can plastic pipe fittings be used for compressed gas systems?

- No, plastic pipe fittings should not be used for compressed gas systems. Compressed gas systems require materials that can withstand high pressures and potential hazards, which plastic fittings may not be able to handle. Metal fittings that are specifically designed and rated for compressed gas systems should be used instead to ensure safety and proper functionality.

Send your message to us

3/4" Plastic Water Pipe Fittings - New PPR Equal Tee Degree for Industrial Fields

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches