Plastic Pipe Compression Fittings - New PP-R Elbow Fittings for Industrial Application from China Professional

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

PP-R (polypropylene random) tube called type three polypropylene pipe and is also called the PP-R pipe or PPR pipe, with energy saving, environmental protection, high strength, corrosion resistance, with smooth inner wall has the advantages of scale, construction and easy maintenance, long service life, widely used in building water supply and drainage, urban drainage city gas and power cable sheath, and industrial fluid transportation, agricultural irrigation construction, municipal, industrial and agricultural fields. The PP-R pipe is made of random copolymerized polypropylene and is extruded into tubes to be molded into tubes.

Application

Distribution for cool and hot water;

Duct for drinkable water system;

Pipes for kinds of high-temperature and low-temperature heating system;

Pipes for heating and cooling settings in solar energy system;

Connecting pipe for air conditioners

Advantages:

1. Greatly reduced linear expansion coefficient, only 1/4 of that of PPR.

2. 100% oxygen tightness, suitable for heating systerm.

3. Improved resistant to impulse under low temperature, resistant to UV-rays.

4. Easily detected by detector when embedded, owing to the metal layer

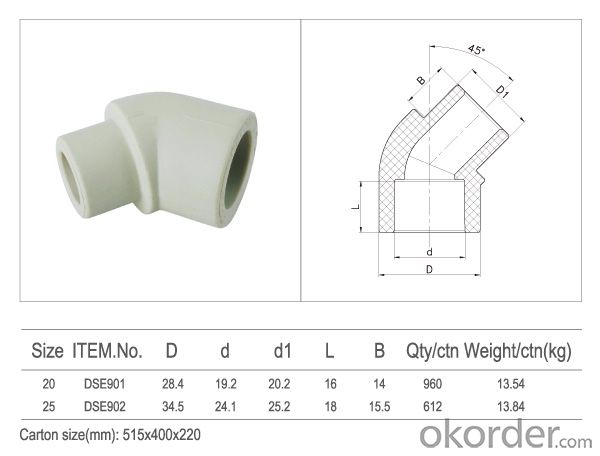

Product Description

Product Show

Why choose us?

(1) Professional factory: We are manufacturer, specializing in manufacturing multilayer PP-R, PE pipe and PP-R, PE pipe fittings for more than13 years, our price is competitive with high quality. And we can delivery product in quick way.

(2) Sample: We can send samples out in 3 days, but the express charge usually paid by your side, but the fee will be rebound when we have formal order.

(3) Rapid response to your needs: We will be answer within 24 hours. Welcome to contact with us if you have any problems. We are looking to cooperating with you.

(4) We hope we can establish long-term and mutual benefit business relation with you. If you have any problem, please kindly feel free to contact me. I will try the best to help you!

- Q: Are plastic pipe fittings environmentally friendly?

- Plastic pipe fittings can be considered environmentally friendly depending on various factors. Although the production of plastic fittings requires the extraction of fossil fuels and energy-intensive manufacturing processes, they have a longer lifespan compared to other materials like metal, reducing the need for frequent replacements. Additionally, plastic fittings are resistant to corrosion and chemical degradation, which can reduce water and energy waste over time. However, proper disposal and recycling are crucial to minimize the environmental impact of plastic fittings, as improper disposal can result in pollution and harm to ecosystems. Therefore, using plastic pipe fittings responsibly and opting for recycling programs can contribute to their overall environmental friendliness.

- Q: Can plastic pipe fittings be used for wastewater treatment plants?

- Yes, plastic pipe fittings can be used for wastewater treatment plants. Plastic fittings are commonly used in wastewater treatment plants due to their durability, corrosion resistance, and cost-effectiveness. They are suitable for various applications such as conveying wastewater, chemical dosing, and distributing treated water. Plastic fittings also offer easy installation, low maintenance, and long service life, making them a practical choice for wastewater treatment plants.

- Q: Antistatic flame retardant PE plastic pipe installation, what should pay attention to?

- When installing the pipe, the distance between the two socket flexible connections shall be no more than 3 meters. When the length compensation is needed, the pipe can be completely inserted into the socket and then out of the 10mm. Flexible connections between pipes and fittings can absorb thermal expansion of pipes up to 10mm.

- Q: Can plastic pipe fittings be used in water slide systems?

- Yes, plastic pipe fittings can be used in water slide systems.

- Q: Are plastic pipe fittings compatible with flange connections?

- No, plastic pipe fittings are not generally compatible with flange connections. Flange connections are typically used for joining metal pipes, while plastic pipe fittings are designed for use with plastic pipes and utilize different connection methods, such as solvent welding or compression fittings.

- Q: How do you remove plastic pipe fittings?

- To remove plastic pipe fittings, you typically need to follow these steps: 1. Turn off the water supply: Locate the shutoff valve for the water supply connected to the pipe and turn it off to prevent any leaks or water flow during the process. 2. Release pressure: Open a faucet connected to the pipe to release any remaining pressure in the system. 3. Cut the pipe: Use a pipe cutter or a hacksaw to cut the pipe a few inches away from the fitting. Ensure a clean and straight cut. 4. Unscrew or release the fitting: Depending on the type of fitting, you may need to unscrew it using a wrench or use a specific tool to release it. Follow the manufacturer's instructions or consult a professional if unsure. 5. Clean and prepare: Remove any burrs or debris from the cut end of the pipe and clean the fitting to ensure a proper connection when installing a new one. Remember, if you are unsure or uncomfortable with the process, it is advisable to seek assistance from a professional plumber.

- Q: Are plastic pipe fittings resistant to hydrostatic pressure?

- Yes, plastic pipe fittings are generally resistant to hydrostatic pressure. They are designed to withstand the pressure exerted by liquids or gases flowing through the pipes. However, it is important to use fittings that are specifically designed for the intended pressure and application to ensure their effectiveness and durability.

- Q: What materials are plastic pipe fittings made of?

- Plastic pipe fittings are commonly made from materials such as PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride), PEX (cross-linked polyethylene), and PP (polypropylene).

- Q: Can plastic pipe fittings be used for water distribution networks?

- Yes, plastic pipe fittings can be used for water distribution networks. Plastic pipes and fittings, such as PVC or HDPE, are commonly used in water distribution systems due to their durability, flexibility, and resistance to corrosion. These fittings provide a reliable and cost-effective solution for transporting water safely and efficiently.

- Q: Can plastic pipe fittings be used for renewable energy systems?

- Yes, plastic pipe fittings can be used for renewable energy systems. Plastic pipes and fittings are commonly used in various renewable energy systems such as solar thermal, geothermal, and hydropower systems. They are lightweight, durable, and resistant to corrosion, making them suitable for transporting water, air, or other fluids used in these systems. Additionally, plastic pipe fittings are often cost-effective and easy to install, making them a popular choice for renewable energy installations.

Send your message to us

Plastic Pipe Compression Fittings - New PP-R Elbow Fittings for Industrial Application from China Professional

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches