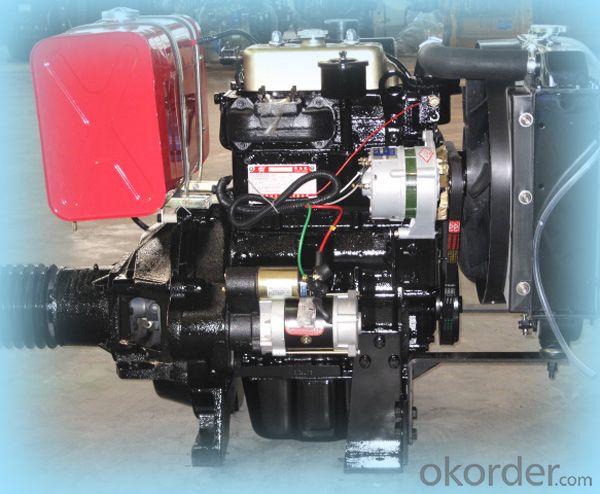

Multi-cylinder diesel engines Vertical,Line,Water Cooling,Four Stroke,Turbocharger

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Multi- cylinder diesel engine, that is, according to the classification of multiple cylinder of the diesel engine cylinder quantity.Diesel engine, it is to use diesel fuel for internal combustion engine, the fuel combustion releasing heat energy into electricity or mechanical energy of the device.

In multi_cylinder diesel engine, each cylinder of each work cycle through four processes: intake, compression, power, and exhaust.In a working cycle is only one stroke is power, and the remaining three are schedule for the auxiliary power stroke create conditions.But all the cylinder of the power stroke is not simultaneously, and a uniform spacing doing work as far as possible.Multi-cylinder diesel engine crankshaft, therefore, uniform motion, work smoothly, and can get enough power, has been widely used in modern automobile industry.

Application field:

multi_cylinder diesel engine is mainly used in agricultural machinery, engineering machinery, automobile industry, ship machinery, electric power industry and other fields.

we have obtained Quality management system certification certificates and Shandong Leiming Heavy Industries Co., Ltd. have obtained the C E certification, Environmental management system certification, Quality management system certification, Health & Safety certification certificates.

Multi- cylinder diesel engine, that is, according to the classification of multiple cylinder of the diesel engine cylinder quantity.Diesel engine, it is to use diesel fuel for internal combustion engine, the fuel combustion releasing heat energy into electricity or mechanical energy of the device.

In multi_cylinder diesel engine, each cylinder of each work cycle through four processes: intake, compression, power, and exhaust.In a working cycle is only one stroke is power, and the remaining three are schedule for the auxiliary power stroke create conditions.But all the cylinder of the power stroke is not simultaneously, and a uniform spacing doing work as far as possible.Multi-cylinder diesel engine crankshaft, therefore, uniform motion, work smoothly, and can get enough power, has been widely used in modern automobile industry.

Application field:

multi_cylinder diesel engine is mainly used in agricultural machinery, engineering machinery, automobile industry, ship machinery, electric power industry and other fields.

- Q: What is the way the engine is lubricated?

- The lubrication strength of each part of the engine depends on the environment of the part, the relative movement speed and the size of the mechanical load and heat load. According to the different lubrication strength, the engine lubrication system uses the following several lubrication methods: (1) pressure lubrication: the use of oil pump, will have a certain pressure of lubricating oil continuously sent to the friction surface. The formation of a certain thickness and can withstand a certain mechanical load without breaking the oil film, as far as possible the two friction parts completely separated to achieve reliable lubrication

- Q: J-20 there is no vector engine?

- If the sun 18, then these test items have to be delayed as now began to test first.

- Q: Please master the Chinese Junjie FRV engine! The

- Manufacturer: Brilliance Automotive Brand: Junjie FRV Model: Junjie FRV1.3MT Comfortable Production Time (Year): 2008 Drive Type: Highest Speed (km / h): 167 Fuel Consumption (L / 100km): 6.2L (Constant speed) Emission standard: Euro 4 with OBD Fuel type: 93 or more unleaded petrol

- Q: Is the engine good or is it good?

- From the point of view of the use, the advantages of the cast aluminum cylinder are light weight and fuel saving by reducing weight. In an engine of equal displacement, the use of an aluminum cylinder engine reduces the weight by about 20 kilograms. With a reduction of 10% of the car's own weight, fuel consumption can be reduced by 6% to 8%. According to the latest information, foreign auto weight has been reduced by 20% to 26% compared with the past. For example, Fawkes used a full aluminum alloy material, reducing the weight of the body, while also enhancing the engine cooling effect, improve the efficiency of the engine, and longer life. From the point of view of oil saving, the advantages of the cast aluminum engine in fuel saving have attracted much attention

- Q: What's the difference between front and rear of a car engine?

- In actual driving, the wheel idling affects the transmission of power. There are two conditions: starting and bending. FF the driver of the car for the two kinds of the most troublesome, one is watched continuously from the power output of the engine, but the car is going round in circles, and when bending, inner tire crazy turn, but did not want to accelerate the reaction. For the MR and RR of the car, the driver as long as the kick accelerator, the car will be in accordance with your thoughts on flying, and can withstand the power of the engine is much larger than FF car, when you drive a horsepower over 250 FF car, you will feel the car began to get out of control, so the fanatical pursuit of power and the speed of the super sports car, MR and RR is the best choice.

- Q: L4 engine and V6 engine performance relative to what is the difference?

- L4, V6 numbers represent the number of cylinders, L is straight, and V is V-type.

- Q: What are the two major structures of an engine?

- 1. crank connecting rod crank connecting rod mechanism includes piston, connecting rod and crank with flywheel. This is the mechanism whereby the engine generates power and turns the reciprocating linear motion of the piston into the rotational motion of the crankshaft. In structural analysis, the body block and the crank link mechanism are often combined together. 2. the valve train includes the intake valve, the exhaust valve, the tappet, the intake camshaft, the exhaust camshaft and the camshaft timing belt (driven by the crankshaft timing gear). The function of the valve train is to charge the combustible gas into the cylinder in time and exhaust the exhausted gas from the cylinder in time.

- Q: How about the tu3af engine?

- PSA will this improvement in TU3JP technology engine named TU3A, and equipped with a large number of the Peugeot brand 107, 206, 207 cars and the Citroen brand C2, C3 car. The 206 use of the TU3AF engine because the general 1.4 liters TU3JP/K in some parts and Beverly, so did not use machine imported spare parts, about 50% of the localization rate to a certain extent reduces the manufacturing cost.

- Q: What country is the Volvo engine produced?

- The engine was made in sweden. Now, the domestic Asia Pacific series engine is produced in china. Volvo (Volvo), a famous Swedish car brand, has been translated as "Regal.". Founded in 1927 in Goteborg, Sweden, the brand was founded by Gustav Larsen and Arthur Gbelson. The Volvo group is the world's leading commercial transportation and construction equipment manufacturer, mainly for trucks, buses, construction equipment, marine and industrial application of driving system and engine components; and the financial services and customer service of the full set of Solutions

- Q: Hippocampus m3 engine and gearbox how

- At the same time M3 with lightweight aluminum alloy cylinder engine, VVT variable valve timing system, the country V emission standards, E-Gas electronic throttle, oil and gas separation system and other five fuel-efficient technology, breaking the same class car 6.0L fuel consumption limit, fuel consumption only

Send your message to us

Multi-cylinder diesel engines Vertical,Line,Water Cooling,Four Stroke,Turbocharger

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords