Mineral Powder Silo Cement Factory Equipment Cement Silo

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mineral Powder Silo Cement Factory Equipment Cement Silo

Main Structure of Mineral Powder Silo

Voltage: 380VPower(W): Cement Silo for Cement Factory

Dimension(L*W*H): As Per Size of Cement Silo for Cement Factory

Weight: As Per Size of Cement Silo for Cement Factory

Certification: ISO CE SGS

Warranty: 1 Year for the Cement Silo for Cement Factory

After-sales Service Provided: Engineers available to service machinery overseas

Safety: Double Direction Pressure Relieve Valve

Bottom Type: Hopper Type For Cement Silo for Cement Factory

Auxillary System-1: Vibrator

Auxillary System-2: Cement Block Breaker System

Auxillary System-3: Dedusting System

Auxillary System-4: Cement High/Low Level Indicator

Auxillary System-5: Cement Loading Pipe

Auxillary System-6: Cement Discharging Mouth

Type: Spiral Folding Lipp Cement Silo for Cement Factory

Customerized Design: Service Available

Main Features for Mineral Powder Coment Silo

| Please Click It to Get More Information → | Size Below 50ton Cement Silo | ||

| Processing Method | Spiral Folding | Bolt Assembly | Welding |

| Materials | Hot Galvanized Steel Can Use Special Materials Required | Carbon Steel Can Use Special Materials Required | Carbon Steel |

| Capacity | 200-7000ton/silo | 50-200ton/silo | Below 50 ton |

| Bottom Type | Flat or Hopper | Hopper | Hopper |

| Foundation Type | Concrete or Steel Structure | Concrete or Steel Structure | Concrete,Steel Structure |

| Application | Cement Storage | Cement Storage | Cement Storage |

| Features | 1) Spiral Folding Treatment Silo has the Max Sealing 2) Big Storage Volume 3) Short Poject Period, Sea Delivery Cost Saving 4) High Solidity 5) Refer Following Advantages for the Detail Features | 1) Bolt Asssembly,Fast Delivery Time, Easy Assemble &Move in Future 2) Medium Quantity Storage 3) Short Poject Period 4) High Solidity 5) Economical | 1) Cheap Cost 2) Small Size Storage 3) Fast Delivery 4) Easy Assembly and Move in Future |

| Optional Auxilliary Systems | 1) Dedust System 2) Level Indicator 3) Loading and Unloading System 4) Cement Block Break Device 5) Explosive-Proof Double Direction Pressure Balance Valve | 1) Dedust System 2) Level Indicator 3) Loading and Unloading System 4) Cement Block Break Device | 1) Dedust System 2) Level Indicator 3) Loading and Unloading System 4) Cement Block Break Device |

| TALK TO US, LET SRON WORK OUT YOUR INTEGRAL PLAN | ||

Spiral Folded Cement Silo for Cement Factory Advantages

1- With Max Assured Safety Consideration Leant from Our Over 3000 Units Silo Experience.

2- Spiral Folding, Max Sealing Performance, Can Have Fumigation System and Store Liquids

3- Connection Part is 5 Times the Thickness of Steel Plate, with Reinforcing Ribs and Wind Rings, Thus Assure Higher Strength and Solidity

4- Spiral Folding Silo is Integral Whole Body and with Longer Life Span to 25-40 Years

5- Fast Assembling and Easy Maintenance, the Project Time is Much Shorter than Bolt Assembly Silo

Application of Our Cement Silo for Cement Factory

1- Can store bulk cement for cement production factory

2- Can store cement used for concrete batching plant

3- Can store cement used for block productine line

4- Can store other mineral powders, coal slag, coal ash, gypsum, coal, special construction materials, rare earth metals etc.

5- Used in hydro-power industry

6- Other special area.

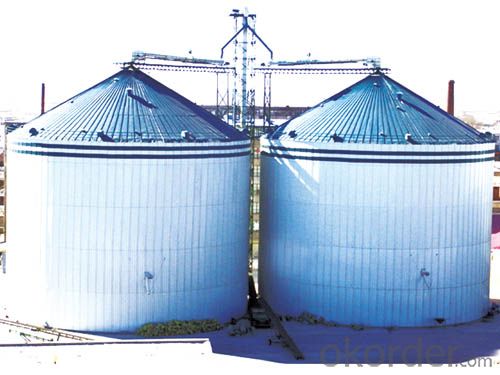

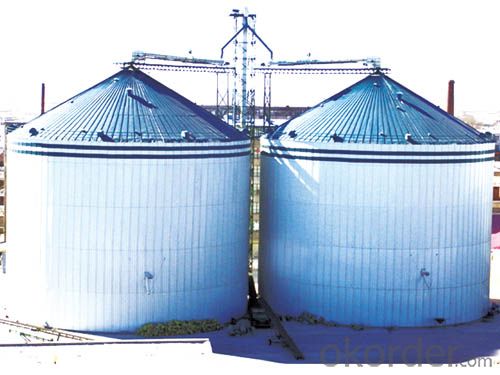

Picture:

- Q: to launch ICBM's you need the president and vp and command control military personell. But you dont need the missile silo personells permission, as a matter of fact, at this time Minuteman III ICBM's can be launched remotely as seen here on the USAF website http://www.nationalmuseum.af.mil/factsheets/factsheet.asp?id=540 so is this a war games situation? what happens in the silos if the missiles are launched without there action? I guess we should know who has the finger on the button or we are in big trouble.

- 0bama can do anything he wants and if you try to stop him- you will be labeled a RACIST H8er and everyone in his tame MSM will cover you with sheite.

- Q: Joseph's Gran Silos? Mannatech Scams?

- Everyone knows they are transmitting stations to contact aliens.

- Q: I have a couple old concrete silos on my property, they are very old. I was told people buy them for things but I'm not sure where to even begin. Do you know how to list old Silos or how to sell them?

- If you need them off your property you might want to offer them for free if they do the removal.

- Q: ....and the thermonuclear bombs glare gave proof through the night that Los Angeles was not there....

- Yeah, I hope it's LA and not New York. It's not on my to do list to get fried by a nuke and/or drenched in gamma radiation.

- Q: Pool of Siloam. Is it Silo-am, Si-loam (si as in quot;sitquot;) or (si as in quot;sightquot;) please answer quickly!

- Hi It would be si-loh-uhm Hope it helps

- Q: Not that I'm afraid that in EMP bomb will happen. Is there anything that can use to protect my electronic equipment?

- The military has circuitry shields to protect certain equipment from EMP damage. The best advice I can give to you is to unplug you electronic devices if you anticipate one coming.

- Q: A typical silo on a farm has many bands wrapped around its perimeter. Why is the spaces between successive bands smaller at the lower portions of the silo ?

- Internal pressure in the silo pushes down and sideways. there is more pressure at the bottom than at the top. So there needs to be more structural strength at the bottom. Wingman

- Q: why is a silo round?

- so the grain can't collect in corners. that's why all your pots and pans have a radius at the bottom so the food can't get stuck in the cracks, check 'em out.

- Q: a silo is to hold 1000 m^3 of corn.what dimensions will minimize surface area? plzz show the full steps

- You make the silo a sphere. 1. The most efficient container, in terms of surface-area-per-unit-volume is a sphere. Use a sphere. If you need a silo of a specific shape, you get the parameters for that shape (ie, height and radius for a cylinder), and use the appropriate equations for surface area and volume. Set volume = 1000 cubic meters. Calculate the minimum value of the surface area. Presumably you'd use the first/second derivative method.

- Q: The Washington Monument: grain storage silo or not?

- Primitive Freemason rocket defending against alien invasion.

Send your message to us

Mineral Powder Silo Cement Factory Equipment Cement Silo

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches