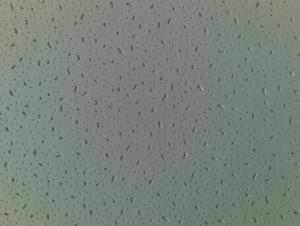

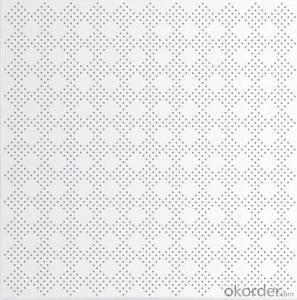

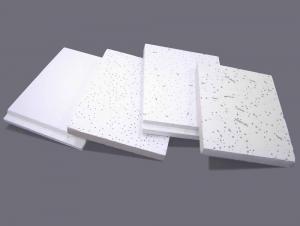

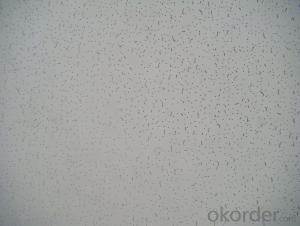

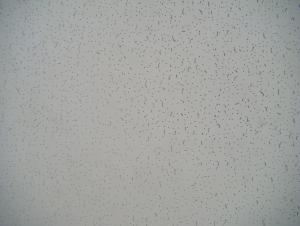

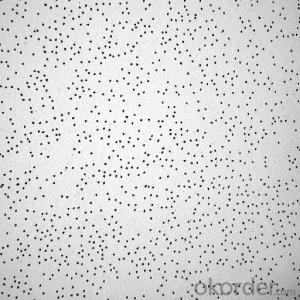

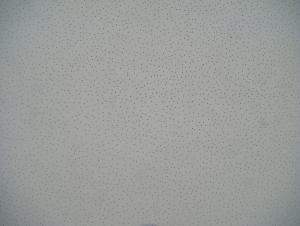

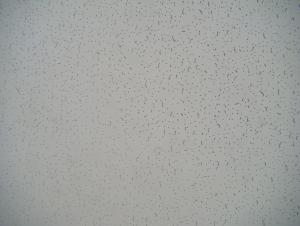

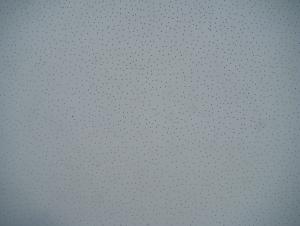

Mineral Fiber Tile Ceiling with Fissured Textures

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Mineral Fiber Ceiling ) Description

Standard Sizes:

595mm*595mm; 1195mm*1195mm; 2’X2’; 2’x4’;

Thickness Range: 8mm – 18mm

Available Textures:

Astral Series; Perforated Series; Fissured Series; Sand Series.

Edge Detail: Square, Tegular

2,Main Features of the (Mineral Fiber Ceiling )

Technical Data:

Density (kgs/m3): 260-320kgs/m3

Noise Reduction Coefficient (NRC): ≥0.45

Humidity Resistance: ≥85%

Fire resistance: Class A Qualification

Light reflect: 0.60-0.80

Application Areas:

Offices, Conference rooms, Corridors, Super Malls, Hospitals and other Public areas

Product Performance:

High absorption & sound insulation;

High humidity & fire resistance;

High light reflection;

Environment-friendly;

3,(Mineral Fiber Ceiling ) Images

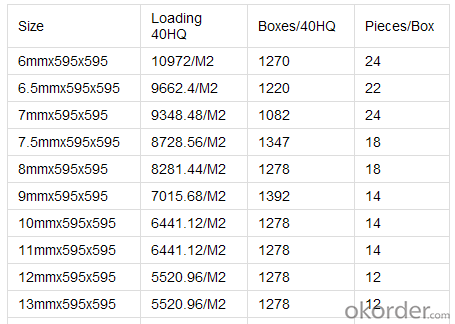

4,(Mineral Fiber Ceiling ) Specification

5,FAQ of (Mineral Fiber Ceiling )

Main Advantage:

1. Use high quality mineral wool as the main raw material, asbestos free, won’t appear needle dust, which might enter human body through the respiratory tract.

2. Use the expansion perlite, which has the function of fire resistance and heat insulation, can effectively reduce the cooling & heating fee. It meets the demand of saving energy and reducing consumption.

3. Use composite fiber and special coating, greatly improving fighting force and resistance to deformation ability.

- Q: What is the quota of the wall trim?

- Material plus artificial.

- Q: Decorative sheet construction method

- You ask is not too one-sided ah? A lot of decorative plate ah, I am looking for decoration for several years, and now I dare not say that all the decorative plates I have seen, you in the depths of the specific tell me what plate, used to do.

- Q: Hi, i am 14 and i weigh about 125 pounds. I play travel baseball in pennsylvania (about 9 months a year) and i play pitcher short stop and second base. Now i usually have a practice every saturday and practices tuesdays and thursdays. But i was wondering if i would be fine to lift monday wednesday and friday before all of the baseball activities? Or do you think i would be sore. And whey protein or muscle milk?Thanks alot!Justin

- i pass to respond to so as. a million) you are able to a minimum of enhance your fastball velocity by 10 mph in case you have the main suitable throwing arm. 2) Use a weighted ball in the previous your prepare throws and throw such as you constantly do. additionally bench press and do well-known weight lifting. It additionally does no longer be undesirable to benefit slightly weight. assorted greater pitchers throw quite quickly. 3) i might say splitter, curve or a cutter, sliders etc. The grips on those pitches are quite important. it is sturdy to apply a fastball and changeup even though it is cool to blend them up slightly. you would be able to even make up your guy or woman pitch 4) prepare, prepare, prepare. in case you're no longer preparation you're no longer getting extra suitable. it is a diffused from throwing an imagenary ball to throwing 70-a hundred pitches. do exactly no longer overdo it. you do no longer choose to throw out your arm at this form of youthful age. (i could be youthful yet i comprehend what i'm conversing approximately) Watch baseball video games and watch the pitchers mechanics. you would be able to learn something.

- Q: Pentium 70 door mounted sound insulation cotton trim board card card is not tight what is the reason

- Hello, this situation, it should be you put the sound insulation place wrong!

- Q: Great Wall c30a column decorative board buckle how to install, with a few buckle?

- Hello, first put the seat belt side of the screw apart, 6 buckle around

- Q: How to use the pendant to the wall to install stone decorative panels

- Not heavy words, with glass glue it, the first brand of the main force points with hot melt adhesive fixed, and then sealed glass glue around.

- Q: Changan cx20 tail box door decoration board how to dismantle

- The fixed screw removed, with a screwdriver out of Alice, and hope to help you, I wish you a happy life!

- Q: 304 stainless steel decorative board price is probably how much

- In general, the price of color stainless steel decorative panels are in a timely manner to a hundred, ranging from 0.6-1.5mm thickness, depending on what you want to do.

- Q: Ask you, decorative plate surface is a transparent primer or wood wax oil

- Can, before and after the edge can brush. With wood wax and transparent primer is two things, with wood wax oil after the general will not use other paint brush, with a transparent primer back cover and then use the paint brush.

- Q: Farm small courtyard of the kang kang skirt with what decorative plate good

- To ask the decorative board which is strong Jin Ke Ma * metal exterior decorative decorative panels easy to install labor hours, the price of preferential policies, large amount of money, moisture and drought, fire and flame retardant security, life comparable to days

Send your message to us

Mineral Fiber Tile Ceiling with Fissured Textures

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords