Microporous Insulation Board CMDS Thermal Conductivity 0.035W/m.k

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Microporous Insulation Board:

CMDS Microporous Insulation Board is is rigid finishing from microporous

technology , with opcified blend of filament reinforced fumed silica, which provides a superb thermal performance.

It is an ideal back-‐up insulation for various industry where

the high temperature is needed, with a long time exposure

of 1150 °C at highest.

STD can be shaped both manually and with stationary wood processing machinery. They can be cut, sawn, drilled and punched. The boards can be fixed in place with glue or by mechanical means such as anchors, pins and clips.

2.Main features of Microporous Insulation Board:

◆ Extremely low thermal conductivity ◆High thermal stability

◆ High thermal stability ◆Environment protection

◆ Easy to handle ◆No harmful inhalable fibers

◆ Resist most chemical attacks

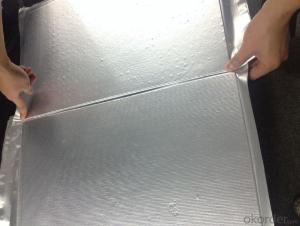

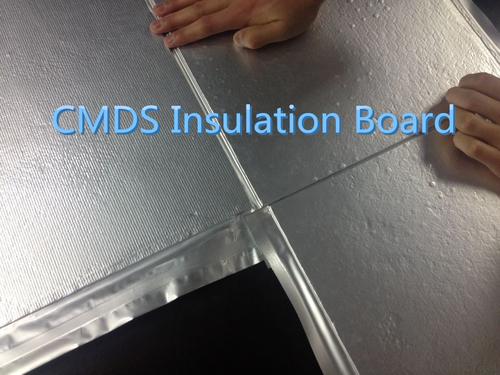

3. Microporous Insulation Board Images:

4. Microporous Insulation Board Technical Parameters

CMDS Microporous Insulation Board can be shaped both manually and with stationary wood processing machinery. They can be cut, sawn, drilled and punched. The boards can be fixed in place with glue or by mechanical means such as anchors, pins and clips.

Application: Back-‐up insulation in industrial furnaces, Fuel cells (SOFC), Thermal Batteries, Aluminium industry ( launders,Smelter.etc. ), Glass & ceramics industry, Petrochemical industry (cracking furnace, reformer), Data loggers. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our board?

Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

A world class manufacturer & supplier of Microporous Insulation Board is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test;

Send your message to us

Microporous Insulation Board CMDS Thermal Conductivity 0.035W/m.k

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords