Mg9990 Magnesium Alloy Ingot Plate Good Quality Ingot Quotation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1. Specification:The Mg Metal is a fairly strong, silvery-white, light-weight metal.

Form: ingot

ingot: (8 ± 0.5) kg / ingot

Specifications: (50-55)cm×(11.5-13.5)cm×(7-7.5)cm

2. Application:

1. The high temperature at which magnesium burns makes it a useful tool for starting emergency fires during outdoor recreation. Other related uses include flashlight photography, flares, pyrotechnics and fireworks sparklers.

2. To photoengrave plates in the printing industry.

3. In the form of turnings or ribbons, to prepare Grignard reagents, which are useful in organic synthesis.

4. As an additive agent in conventional propellants and the production of nodular graphite in cast iron.

5. As a reducing agent for the production of uranium and other metals from their salts.

6. As a sacrificial (galvanic) anode to protect underground tanks, pipelines, buried structures, and water heaters.

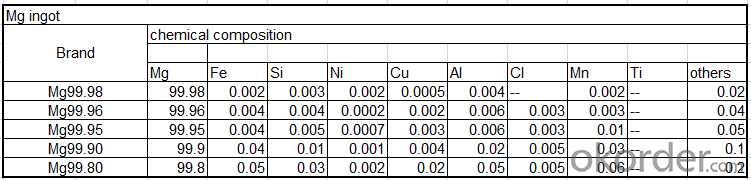

3. Mg Alloys Metal (Ingot)

4. Advantages:

Good Quality ............... The most important factor we care.

Competitive Price ........ For our mutual benefit.

Prompt delivery ........... Abundant production ability, storage ability and manpower.

Excellent Service ......... Customer always first.

Now our main markets in Asia and Europe, to the future we will set up sales network in more than 200 countries around the world.

Image

What is Magnesium Alloys?

Magnesium alloys are mixtures of magnesium with other metals (called an alloy), often aluminum, zinc, manganese, silicon, copper, rare earths and zirconium. Magnesium is the lightest structural metal. Magnesium alloys have a hexagonal lattice structure, which affects the fundamental properties of these alloys. Plastic deformation of the hexagonal lattice is more complicated than in cubic latticed metals like aluminium, copper and steel; therefore, magnesium alloys are typically used as cast alloys, but research of wrought alloys has been more extensive since 2003. Cast magnesium alloys are used for many components of modern automobiles, and magnesium block engines have been used in some high-performance vehicles; die-cast magnesium is also used for camera bodies and components in lenses.

Practically, all the commercial magnesium alloys manufactured in the United States contain aluminum (3 to 13 percent) and manganese (0.1 to 0.4 percent). Many also contain zinc (0.5 to 3 percent) and some are hardenable by heat treatment. All the alloys may be used for more than one product form, but alloys AZ63 and AZ92 are most used for sand castings, AZ91 for die castings, and AZ92 generally employed for permanent mold castings (while AZ63 and A10 are sometimes also used in the latter application as well). For forgings, AZ61 is most used, and here alloy M1 is employed where low strength is required and AZ80 for highest strength. For extrusions, a wide range of shapes, bars, and tubes are made from M1 alloy where low strength suffices or where welding to M1 castings is planned. Alloys AZ31, AZ61 and AZ80 are employed for extrusions in the order named, where increase in strength justifies their increased relative costs.

Magnesium L-threonate is used as a dietary magnesium supplement

Overdose from dietary sources alone is unlikely because excess magnesium in the blood is promptly filtered by the kidneys. Overdose with magnesium tablets is possible in the presence of impaired renal function. There is a single case report of hypermagnesemia in a woman with normal renal function using high doses of magnesium salts for catharsis. The most common symptoms of overdose are nausea, vomiting and diarrhea; other symptoms include hypotension, confusion, slowed heart and respiratory rate, deficiencies of other minerals, coma, cardiac arrhythmia, and death from cardiac arrest.

Plants require magnesium to synthesize chlorophyll, essential for photosynthesis. Magnesium in the center of the porphyrin ring in chlorophyll functions in a manner similar to the iron in the center of the porphyrin ring in heme. Magnesium deficiency in plants causes late-season yellowing between leaf veins, especially in older leaves, and can be corrected by applying to the soil either Epsom salts (which is rapidly leached), or crushed dolomitic limestone.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

CNBM, The Fortune 500. A world class manufacturer & supplier of magnesium alloys ingots plates&sheets, magnesium alloy bars, Magnesium alloy slabs,magnesium alloy wires,magnesium alloy tubes and etc.. bases in China.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;

We would like to offer free samples for your inspect and check.

We have advanced manufactured equipments,such as hot rolling equipment. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③What is your main markets?

Our main markets are from Europ, America and Aisa. Such as Germany,Czech, Poland, England, Canada, Korea, Turkey etc.

- Q: Causes of high manganese content in magnesium ingot

- Magnesium in the air in the combustion reaction of oxygen, magnesium and Magnesium Oxide in the air, and the quality of the quality of the resulting Magnesium Oxide equal in response to magnesium and oxygen quality, so the quality of the product than the quality of the original magnesium increases.

- Q: What is the black powder on the surface of magnesium ingot AM50A?

- These are commonly used in the die casting magnesium alloy brand.

- Q: What are the surface defects of magnesium alloy rolling?

- General magnesium alloys will not be rolled, so that the rolled products are easy to oxidize and not conducive to preservation

- Q: What harm does magnesium alloy have to human body?

- Yes, the alloy is usually aluminum, magnesium, iron and the like, may cause chronic aluminum poisoning, that is, excessive accumulation of aluminum in the body, affecting intelligence and other physical functions.

- Q: What are the generally feasible surface treatment methods for magnesium alloy die castings?

- You ask is the appearance of the surface treatment of magnesium alloy, magnesium alloy because of the limited potential difference, so the appearance of the surface treatment on magnesium alloy or zinc alloy as Aluminum Alloy appearance easy or style, the general appearance of the 1 surface treatment) surface temperature paint, 2) anodic oxidation treatment, 3) chemical nickel plating, plating surface treatment, 4) 5) 6) electrophoresis surface treatment, surface coating treatment, 7) PVD appearance. As for the surface of phosphoric acid, chromic acid, manganese and other chemical immersion solution or to do what should be included in the sandblasting, surface oxidation treatment, and drawing, engraving and so on processing is additional processing surface appearance of another way. Basically, it looks like aluminum alloy or zinc alloy, but the key point is that the process is different from the technical complexity. So the reason why the general magnesium alloy is more difficult to produce is that it is here.

- Q: Why the cost of ferrosilicon production will lead to a rebound in the price of magnesium ingot?

- The rising price of ferrosilicon means that the cost of raw material will rise and magnesium ingot producers will inevitably raise their prices.

- Q: The industrial application of magnesium and the main title and technical difficulty of producing magnesium products with magnesium chloride as raw material

- The chemical property of magnesium is active, in the metallurgical industry by using, steel and non-ferrous metal casting, with magnesium as desulfurization agent, cleaning agent, as reducing agent in the production of rare metal. In the chemical industry, magnesium can be used as a dehydrating agent of organic compounds or directly with organic compounds and preparation of magnesium powder. In recent years, in the use of magnesium powder spray, coating, anticorrosion industry is more and more big, the amount of silicon and polysilicon and powder metallurgy die casting is also great.

- Q: What are the differences between aluminium magnesium alloy, aluminum alloy and plastic steel?

- In the fireworks production process plays a very important role in reducing agents, but also as a white light agent and lighting agentMagnesium alloy is magnesium ingots and aluminum ingots in protective gas melted into. For a long time about the structure of Al Mg alloy with two kinds of argument. One theory is that magnesium alloy is a simple physical mixture; another is magnesium alloy changes inside the crystal structure, is not a simple physical mixture.

- Q: Will the enterprises that produce sponge titanium use magnesium ingots?

- Can be used, or can not be, according to process methods and the production of sponge too, one way is to use magnesium reduction method

- Q: What is magnesium aluminum alloy and what is its use?

- Magnesium alloy molecular formula: Mg4Al3 molecular weight: 178.22 color is brown, the proportion is about 2.15g/cm3, the melting point of 463 DEG C, when combustion temperature reaches 2000 DEG -3000 DEG. In fireworks production process plays a very important role in reducing agent, can also be used as white lighting agent and agent.

Send your message to us

Mg9990 Magnesium Alloy Ingot Plate Good Quality Ingot Quotation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords