Metallurgical Coke of the size 30-80mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Metallurgical Coke of the size 30-80mm Description:

Coke is made by high temperature metallurgical coke for blast furnace smelting, casting and gasification. Occurring in the process of coking after recovery and purification of coke oven gas is a high calorific value of fuel, is an important industrial raw material in organic synthesis.

Coke is mainly used for blast furnace ironmaking and used for copper, lead, zinc, titanium, antimony, mercury and other non-ferrous metal smelting of blast furnace, reducing agent, compound and the function of stock column frame.

Blast furnace with Coke instead of charcoal, which laid a foundation for the large-scale of modern blast furnace, is a major milestone in the history of metallurgy.

2. Main Features of the Metallurgical Coke of the size 30-80mm :

• Quality assurance

• Mutual benefit

• Preferential price

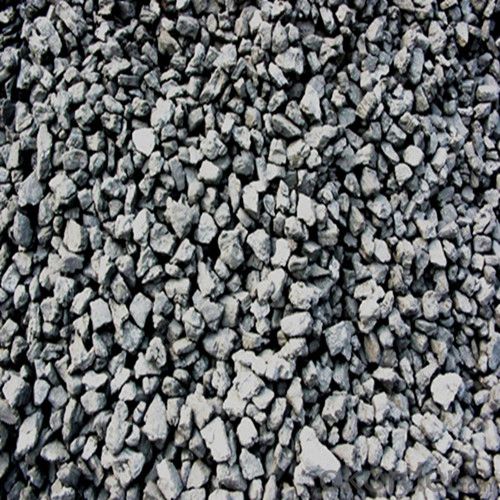

3. Metallurgical Coke of the size 30-80mm Images:

4. Metallurgical Coke ofthe size 30-80mm Specification:

Parameters | Guarantee |

Moisture (ARB) | 5% max |

Ash (DB) | 12.50% max |

Volatile Matter (DB) | 1.4% max |

Sulphur (DB) | 0.7% max |

Phosphorus (DB) | 0.035% max |

CSR | 60% min |

CRI | 28% max |

M40 | 82% min |

M10 | 8% max |

Size 30-90 mm | 90% min |

+90 mm | 5% max |

-30mm | 5% max |

Mean Size | 52 mm |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

1) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2) What are coke's main physical properties?

The average heat capacity is 0.808 kj/(KGK) (100 ℃), 1.465 kj/(KGK) (1000 ℃)

Thermal conductivity is 2.64 kj/(MHK) (room temperature), 6.91 kj/(MHK) (900 ℃);

Ignition temperature (air) is 450-650 ℃.

3) How about your company?

Our company began to export coke when China cancelled 40% of coke export tariffs and quotas on January 1, 2013. We export many kinds of coke, such as CSR60 % and CSR 62% metallurgical coke (met coke), the NUT coke of 20 to 50 mm, coke breeze of 3 to 6 mm, and so on.

- Q: What is the difference between metallurgical coke and chemical coke

- Quality index of cokeCoke is a solid product of high temperature carbonization, the main component is carbon, is a crack and irregular pore structure (or porous). The number of cracks has a direct impact on the strength and crushing strength of the coke, the index is generally measured in terms of crack degree (the number of cracks in the unit volume coke). The index of pore structure is mainly expressed by the porosity rate (the percentage of the total volume of coke), which affects the reactivity and strength of coke. Different uses of different coke porosity index requirements, the general requirements of metallurgical coke porosity in the 40 ~ 45%, 35 ~ 40% in coke, coke export demand in about 30%. Coke crack degree and the porosity level, and the coking coal has a direct relationship, such as coal based coke refining, crack, high porosity, low strength; with coal as the foundation of the coal refining coke crack less, low porosity and high strength. The strength of coke is usually represented by two indices of crushing strength and abrasion resistance. Coke crushing strength refers to coke can resist foreign impact force without ability along cracks or defects at the broken, represented by the M40 value; wear strength of coke coke refers to the ability to resist external friction without surface of glass forming debris or powder, said M10. The cracking degree of coke affects the M40 value of its breaking strength, and the pore structure of coke affects the M10 value. There are many methods for determination of M40 and M10 value method, commonly used in our country the German migon drum test.

- Q: What is cokeWhat applications are, what is the fire of Malachite copper

- Coke is a kind of reducing agent (C), under the heating conditions and some of the oxidation reduction reaction, can restore some important minerals, such as steel mills, etc..

- Q: We would like to export a batch of coke, I would like to know what information is required for a permit

- Step 1: apply for an electronic key:The electronic key is equivalent to the enterprise identity authentication, after the application is similar to online banking U shield, the cost of 350 yuan. Including the physical Key ($150) and digital certificate price ($200), where Key is a one-time fee, digital certificates for the annual cost, valid for one year.

- Q: The chemical composition of coke is m10.m25

- Quality index of cokeThe quality index of coke coke [] is a solid product of high temperature carbonization, the main ingredient is carbon, is the pore structure has a crack and irregular (or pore porous). The crack number directly affects the coke strength and crushing strength, the index of general degree (refer to how to crack crack length unit the volume of coke in the measure.) to measure the pore structure of the main indicators for the porosity (coke pore volume only percentage of the total volume) that it affects the coke reactivity and strength

- Q: What is the sample quantity of coke moisture test? What is the test time? How many degrees? That is the national standard.

- Test procedureDetermination of total moistureA, said the samples size less than 13mm with pre dried and weighed for about 500g (referred to 1g), smooth specimen,B, a sample tray is placed on the 170 a 180 C in the drying box, LH removed after cooling, weighing 5min. C, check dryness, each time 10min, until the two consecutive quality difference in LG, calculate the quality of the last time.Determination of moisture content of samplesA, with the weighing bottle drying to constant quality in advance and has quickly called weighing samples size less than 0.2mm uniform mixing of the 1 + 0.05g (referred to 0.0002g), flat on the weighing bottle.B, will be filled with a sample of the bottle to be placed in the 105-110 drying box drying 1H, remove the weighing bottle immediately covered with lid, put into the dryer to cool to room temperature (about 20min), weighing.C, check of dry, insult 15min, until two consecutive poor quality in 0.001g, take the quality of the last calculation, if quality is weight gain first calculated on the basis of.Five, the calculation of test resultsCalculation of total moisture content according to formula (L):

- Q: The total amount of heat released by the fully burnt 200g coke is 60% by mass of 10kg water absorption [q coke =3.0 * 107J/kg, C water =4.2 * 103J/ (kg = C)], q:(1) how much heat is absorbed by water?(2) if the initial temperature of water is 10 degrees C, then, after absorbing heat, the temperature will rise to how much?

- Dry water temperatures:Delta t=Q ceilingC water m water=3.6 x 106J4.2 x 103J/ (kg * c) * 10kgC = 85.7,At the end of a water temperature t=t0+ t=20 C +85.7 =105.7 oc,

- Q: I don't understand. With coke, then the rest of the coke, they are selling it?

- If most of the solid fuel is burning coal, but coking coal, which is very strong viscosity of coal is not good, it is very interesting to use the individual plant with it, the purpose is to change the fuel characteristics.Coking coal and coke, commonly used in metallurgical industry.Coal will be heated to a process of coke, but you really want to get coke, to specialized production. Power plants do not produce coke, they only have gray coke

- Q: Braised meat burning coke, iron black layer, I do not know how to clean, please help answer

- If the paste pot may wish to try the following several waysBrush pot1, with hot water can be, it is easy to wash, do not use wire brush the ball, put the pot brush bad, if it is aluminum brush used for cooking after eating on the body is very good. (if you must brush it, you can use the cloth to replace the steel ball)

- Q: What is the difference between the industrial analysis of coke and the industrial analysis of coal samples

- Coke GB/T 1996-2003, volatile coke is the most difficult to do

- Q: the CO reduces the iron oxide, and the part of CO burns, and the whole process will release a lot of heatCheck information, combined with the knowledge of the professional knowledge, for reference purposes only!

- Coke index:The mechanical strength of the mechanical strength of ash sulfur%% volatile(crush strength M40) (abrasion strength M10)No greater than 12 is not greater than 0.6 not less than 80 not greater than 8 not greater than 1.9Two level 12.01-13.50 0.61-0.80 not less than 76 not greater than 9 not greater than 1.9Three level 13.51-15.00 0.81-1.00 not less than 72 not greater than 10 not greater than 1.9

Send your message to us

Metallurgical Coke of the size 30-80mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords