MET COKE of Coke Strength after Reactivity 65

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Metallurgical Coke of Coke Strength after Reactivity 65 Description:

Coke is made by high temperature metallurgical coke for blast furnace smelting, casting and gasification. Occurring in the process of coking after recovery and purification of coke oven gas is a high calorific value of fuel, is an important industrial raw material in organic synthesis.

Coke is mainly used for blast furnace ironmaking and used for copper, lead, zinc, titanium, antimony, mercury and other non-ferrous metal smelting of blast furnace, reducing agent, compound and the function of stock column frame.

Blast furnace with Coke instead of charcoal, which laid a foundation for the large-scale of modern blast furnace, is a major milestone in the history of metallurgy.

2. Main Features of the Metallurgical Coke of Coke Strength after Reactivity 65:

• Quality assurance

• Mutual benefit

• Preferential price

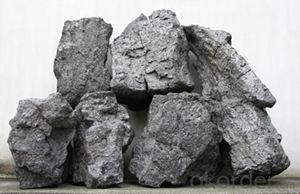

3. Metallurgical Coke of Coke Strength after Reactivity 65 Images:

4. Metallurgical Coke of Coke Strength after Reactivity 65 Specification:

Parameters | Guarantee |

Moisture (ARB) | 5% max |

Ash (DB) | 12.50% max |

Volatile Matter (DB) | 1.4% max |

Sulphur (DB) | 0.7% max |

Phosphorus (DB) | 0.035% max |

CSR | 60% min |

CRI | 28% max |

M40 | 82% min |

M10 | 8% max |

Size 30-90 mm | 90% min |

+90 mm | 5% max |

-30mm | 5% max |

Mean Size | 52 mm |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

1) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2) What are coke's main physical properties?

The average heat capacity is 0.808 kj/(KGK) (100 ℃), 1.465 kj/(KGK) (1000 ℃)

Thermal conductivity is 2.64 kj/(MHK) (room temperature), 6.91 kj/(MHK) (900 ℃);

Ignition temperature (air) is 450-650 ℃.

3) How about your company?

Our company began to export coke when China cancelled 40% of coke export tariffs and quotas on January 1, 2013. We export many kinds of coke, such as CSR60 % and CSR 62% metallurgical coke (met coke), the NUT coke of 20 to 50 mm, coke breeze of 3 to 6 mm, and so on.

- Q: Standard grade two grade coke standard

- 5, the moisture in the coke: water fluctuations will make the measurement of coke is not allowed, resulting in fluctuations in furnace conditions. In addition, the increase in the moisture content of Coke will make the M04 high, M10 is low, the drum index error.6, the screening of coke composition: in the blast furnace coke particle size is also very important. In the past, the particle size of coke in our country is as follows: the coke size of large coke oven (1300 - 2000 square meters) is greater than 40 mm; the coke size of medium and small blast furnace is larger than 25 mm. However, some of the steel test shows that the coke particle size of 40 - 25 mm as well. Larger than 80 mm of coke to be whole, so that the particle size range. The coke block is uniform, the gap is large, the resistance is small, and the furnace condition runs well.

- Q: What is the concept, relationship and difference between coke and coke? The main difference and contact, thank you

- Formed coke is a product obtained through several steps:(1) environmental protection continuous high efficiency carbonization furnace(2) the use of anthracite powder to produce plastic molding coke and supporting technology(3) a new type of environmentally friendly carbonization carbonization furnace without three wastes discharge.(4) hydraulic press

- Q: Ask: coking coke tower tower and what is the relationship?If you can give a working principle to explain what is better!Coking tower in oil coking plant

- Coking plant production capacity on the exclusion of the tower is also on the two: first, the coal tower; the two is coke bin;

- Q: What are the indicators of first grade coke and the two grade coke?

- Two level 12.01-13.50 0.61-0.80 not less than 76 not greater than 9 not greater than 1.9Three level 13.51-15.00 0.81-1.00 not less than 72 not greater than 10 not greater than 1.9

- Q: After the long-term use of non stick pan, oil stains can not be effectively removed, over a long period of time in the non stick coating on the formation of a layer of coke, the effect of losing non stick. As a result of this layer of coke is relatively dense and smooth, scouring cloth has been ineffective, steel ball can not be used to damage the coating, what chemical or physical methods to remove this layer of coke?

- Soak in hot water for a few hours (or a day and night).Two, with cooking shovel (Mason's Pihui knife is best) to remove surface soft.Three, the same with a spade close to the bottom of the pot to eradicate. Until the last thing left is black.

- Q: What kind of coke is needed for smelting special steel

- It is necessary to add coke, pellet, sinter ore, ore and other materials into the blast furnace in a certain proportion, batch and sequence, and then to produce molten iron in the reducing atmosphere of the blast furnace

- Q: 8 points will be isolated from the air to enhance the heat of coal, in addition to the main coke, but also the material listed in the following table: No.

- Ethylene containing carbon carbon double bonds can react with bromine and bromine, and reaction of bleaching, b.:

- Q: Why in the blast furnace ironmaking with coke instead of charcoal why coke can produce heat to improve the heat of the furnace how to produceWhy in the blast furnace ironmaking with coke instead of charcoal why coke can produce heat to improve the heat of the furnace how to produce

- The reaction of the blast furnace ironmaking is the reduction reaction: the coke produces CO in the furnace, the CO reduces the iron oxide, and the part of CO burns, and the whole process will release a lot of heatCheck information, combined with the knowledge of the professional knowledge, for reference purposes only!

- Q: How long should it be to store coke in the open air

- And the most important thing is to avoid the sun. Coal and coke, like the sun, the temperature inside the stack is very high. So try to cool down.

- Q: The two day of the fire is not wang you have a good way to have any good way. Such online

- Under the condition of isolated air, the bituminous coal is heated to 950-1050 DEG C, and finally, the coke is made by drying, pyrolysis, melting, bonding, solidification and shrinkage.

Send your message to us

MET COKE of Coke Strength after Reactivity 65

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches