MET COKE CSR65

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

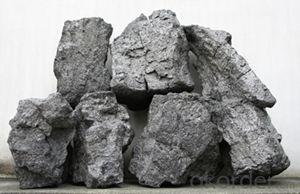

CNBM MET COKE of CSR65

We export many kinds of coke, such as metallurgical coke (met coke) of 40-100 mm, theNUT coke of 20 to 50 mm, coke breeze of 3 to 6 mm, and so on. The main source isShanxi coking plant.

Is containing ferrous carbonate minerals, the main ingredients for FeCO3, pewter, proportion of around 3.8.This kind of ore mostly contains considerable amount of calcium salt and magnesium salt.Because of carbonate ions in the high temperature of about 800 ~ 800 ℃ will absorb a lot of heat and gives off carbon dioxide, so most of us look again after this kind of ore roasting them join the blast furnace.

The intended use of CNBM MET COKE of CSR65

Our CNBM MET COKE of CSR65 are ideal for:

· Power plant

· Steel mills

The advantages of CNBM MET COKE of CSR65

Not only are OKorder's CNBM MET COKE of CSR65 of the highest quality and reliability, we are able to quickly ship orders within 20 days of receiving a deposit or original L/C.

Main features of CNBM MET COKE of CSR65

l Unique Frame Design For Easy Installation

l High energy conversion efficiency

l Reliable performance

FAQ:

Q1: How about your company?

A:Our company began to export coke when China cancelled 40% of coke export tariffs and quotas on January 1, 2013. We export many kinds of coke, such as CSR60 % and CSR 62% metallurgical coke (met coke), the NUT coke of 20 to 50 mm, coke breeze of 3 to 6 mm, and so on.

Metallurgical Coke of Coke CSR65 Images:

Specifications:

At present, the main customers are NOBLEGROUP, IMR and so on. Our main overseas markets are Japan, India, Brazil, Iran,Vietnam, and so on.Let me know your demands then I can check availability.

- Q: What are the main uses of coke

- A small smelting industry, used to produce calcium carbide, carbon disulfide, phosphorus etc.. In the iron and steel enterprises, coke powder is also used as sintering fuel. Coke can also be used as raw material for the preparation of raw materials for the synthesis of water gas. ??4, in order to make the blast furnace operation to achieve better technical and economic indicators, smelting coke (metallurgical coke) must have the appropriate chemical and physical properties, including the smelting process of thermal properties.

- Q: F.C Ash S V.M H2O SizeMore than 85 less than 15 less than 8 less than 0.8 less than 1.5 10-70mm over 90%,I would like to ask, what is the size of the corresponding coke? Metallurgical coke or something else, there is no relevant information about, thank youF.C = 85, Ash = 15, H2O = 8, S = 0.8, V.M = 1.5, Size:10-70mm 90% and above, so clear, like the product, the current price?

- Two metallurgical coke: fixed carbon 84.5-85%; calorific value 7000cal/kg; ash < 13.5%; volatile < 1.9%; all 6% "0.7%" water; sulfur;

- Q: Coke boiler belongs to coal-fired boiler

- Coke is commonly used in the smelting industry, such as iron smelting converter, steel blast furnace, ferroalloy electric furnace, etc.

- Q: China's coke iron smelting began in what time?

- Han also invented the "fried steel law", that is, the use of pig iron "fried" mature iron or steel of the new process, the product is called steel. At the same time, the rise of "100 steelmaking" technology. The Eastern Han Dynasty (AD 25 ~ 220), when the emperor of the Ming Dynasty, invented the hydraulic blast furnace, that is, "water discharge". The invention of ancient water row in China, about 1100 years earlier than europe. After the Han Dynasty, the method of steel. "Qi Shu Qi, even referred to as" places "big steel", later known as the filling steel, also known as steel group. This is another important achievement of the ancient steelmaking technology in china. According to the "Encyclopedia of" records: Chinese is the earliest use of coal iron country, the Han Dynasty have been tried, song and Yuan dynasties have been popularized. To the Ming Dynasty (AD 1368 ~ 1644) has been able to use coke smelting pig iron.

- Q: Why does Coke provide heat when it is fired, it reacts only at high temperatures and why it is needed to provide heat?Which is the exothermic reaction, carbon dioxide or carbon monoxide?

- In addition to the reaction of iron and iron oxide will react C+O2=CO2; reaction exothermic;

- Q: Some experimental results summarized the following two facts: the coke can not be used to restore aluminum mine, but it can be used for the reduction of copper and iron; no containing copper sulfate solution with tin, thus the activity sequence C, Al, Cu, Fe of the four elements is ______.

- Coke can not be used to restore aluminum ore, but can be used to restore copper and iron ore, indicating that aluminum is the most active

- Q: Coke and coal is one thing

- How coal is formedCoal has been hailed as the black gold, the food industry, it is one of the main sources of energy used in the human world since eighteenth Century. Although its important position has been replaced by oil, but in the future for a long period of time, due to the exhaustion of petroleum, inevitable decline, but because of the huge reserves of coal, coupled with the rapid development of science and technology, the new technology of coal gasification is becoming more mature and widely used, coal will become one of the human production life cannot substitute energy.

- Q: What is the essential difference between coal and coke?

- [coal]Coal is a kind of solid combustible mineral which is buried in the underground plants and has been formed by the complex biochemical and physicochemical changes. Coal is a kind of solid combustible organic rock, which is mainly formed by the chemical reaction of the remains of plants.

- Q: Why in the blast furnace ironmaking with coke instead of charcoal why coke can produce heat to improve the heat of the furnace how to produceWhy in the blast furnace ironmaking with coke instead of charcoal why coke can produce heat to improve the heat of the furnace how to produce

- Under the condition of isolated air, the bituminous coal is heated to 950-1050 DEG C, and finally, the coke is made by drying, pyrolysis, melting, bonding, solidification and shrinkage

- Q: Distinction and distinction of cokeSoil coke, improved coke, coke machine coke do, what is the difference between

- Two, the type of coke:Coke is usually divided by use of metallurgical coke (including blast furnace coke, coke and iron alloy coke, calcium carbide and coke gasification etc.) with coke. The pressurized pulverized coal forming coal, coke carbonization etc. in the new postprocessing process called Formcoke.1, metallurgical coke, metallurgical coke is coke, coke, iron alloy coke and non-ferrous metal smelting coke for metallurgical coke collectively. More than 90% are used in blast furnace, the furnace coke often called metallurgical coke.The metallurgical coke quality standard (GB/T1996-94) made in China is the quality standard of blast furnace

Send your message to us

MET COKE CSR65

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches