Countdown Packaging Tape Masking Film for Car Paint - China Factory Hot

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 30000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Masking Film PE Car Paint China Factory Hot

1. Structure of Masking Film Description

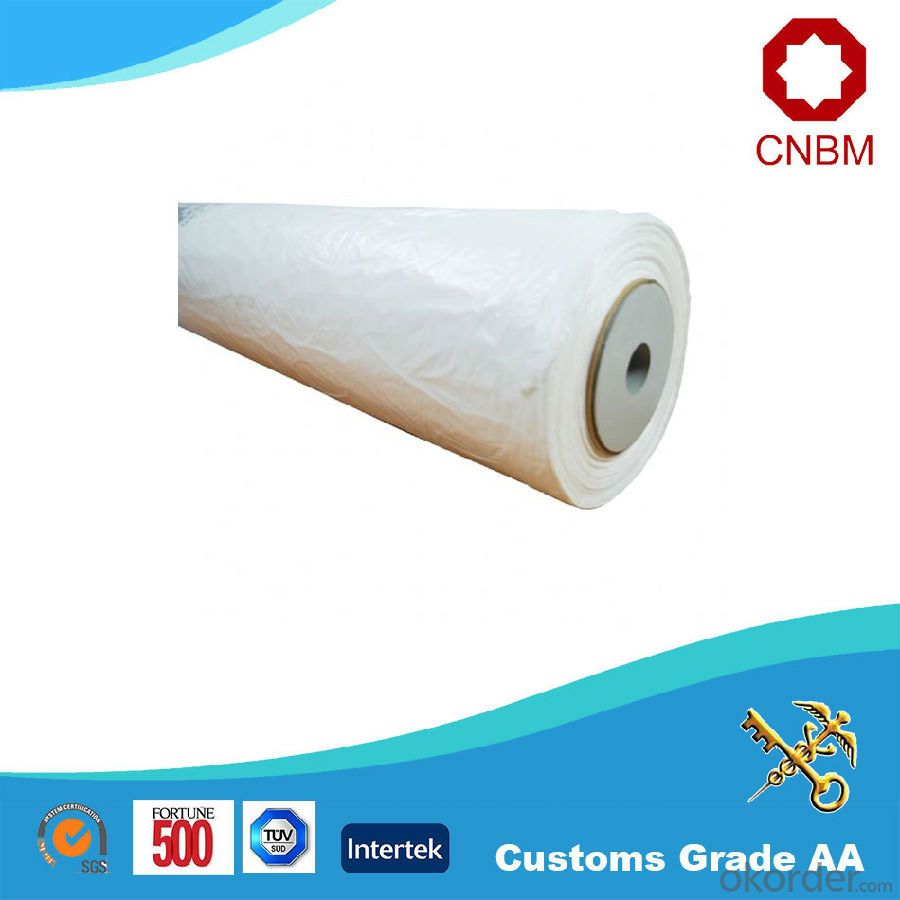

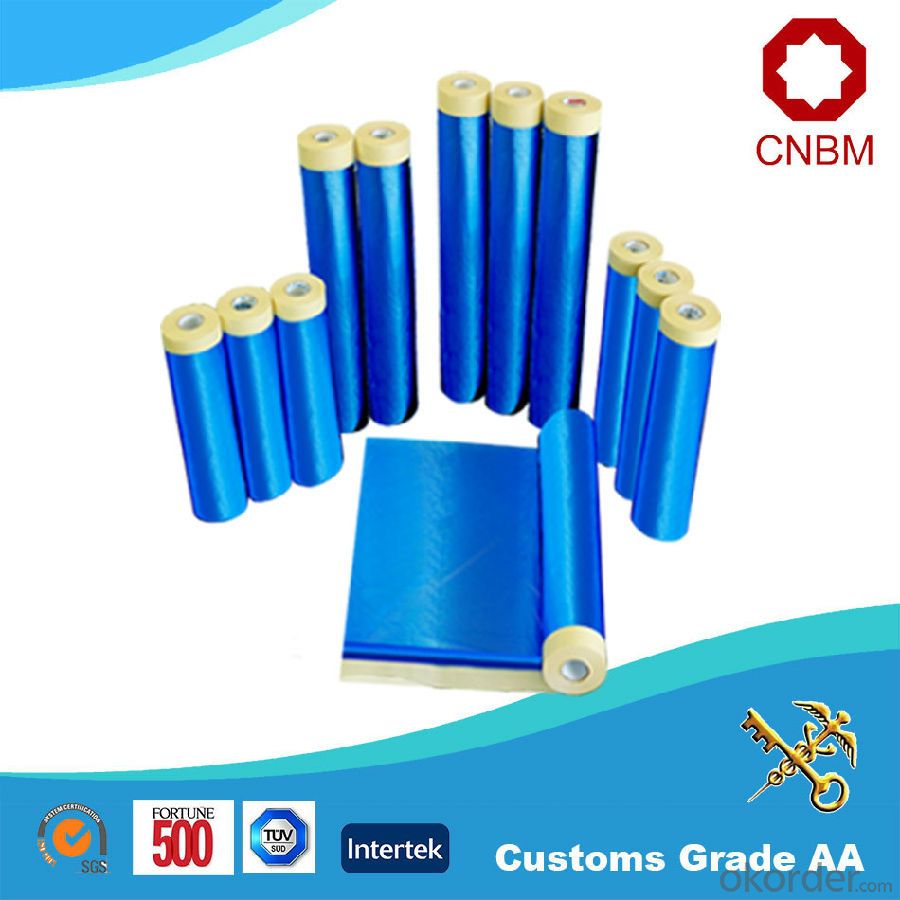

Masking Film is of HDPE film and masking tape. A convenient, pretaped plastic film which unfolds to cover and protect various surfaces while painting. Specially treated film clings to surfaces and is easy to clean up.

2. Main Features of Masking Film

Strong and Flexible

Multi-Folded easy to use

Competitive price

Indoor/outdoor painting

Sunlight stable even on glass

3. Masking Film Images

4. Masking Film Specification

Tape Size | Rolls/Carton | Weight/Roll(kg) | Jointing Material | Temperature Resistance |

330mm*30M | 20 | 0.12 | Crepe parer | -5—60°C |

550mm*30M | 50 | 0.17 | Crepe parer | -5—60°C |

1100mm*30M | 25 | 0.30 | Crepe parer | -5—60°C |

1400mm*30M | 10 | 0.39 | Crepe parer | -5—60°C |

5. FAQ

Q1. What is our company?

CNBM International Corporation is a state-owned company. As World Top 500 Company, we have clients from over 120 countries and overseas branches in 5 countries. We specialized in adhesive tape for over 20 years, with SGS and ISO9001 certified and Grade AA for Export.

Q2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

Q3. What is the Packing?

It is wraped by hot shrink POF film with adhesive lable. 50 rolls or 25rolls packing in to one carton .

- Q: Can packaging tape be used for other purposes?

- Packaging tape has a wide range of uses beyond its intended purpose of sealing packages. Its strong adhesive properties and durability make it suitable for various applications. One popular alternative use for packaging tape is organizing and bundling items together. It can be used to sort and secure cables, cords, loose items, or similar objects, effectively keeping them organized. Additionally, it can be used to temporarily attach items like posters or decorations to walls or surfaces without causing any damage. Furthermore, packaging tape is great for crafting and DIY projects. Its adhesive nature allows it to create both temporary and permanent bonds between different materials. It can repair torn papers, create labels or tabs, or even make personalized stickers. Its versatility, available in different widths and lengths, makes it a valuable tool for creative endeavors. Moreover, packaging tape can be used for household fixes and repairs. Its strong adhesive properties can temporarily mend broken items or reinforce weak joints. It can also provide a temporary seal for minor leaks or cracks until a proper repair can be done. In conclusion, packaging tape's strong adhesive properties and versatility make it suitable for various purposes beyond sealing packages. Whether for organizing, crafting, or quick fixes, having packaging tape on hand can be highly useful.

- Q: Does packaging tape have any specific safety precautions?

- Yes, packaging tape does have some specific safety precautions that should be followed. Firstly, it is important to handle packaging tape with care and avoid any sharp or sudden movements that could cause injury. While packaging tape itself is not typically dangerous, mishandling it could result in cuts or punctures. Additionally, it is essential to use the appropriate type of packaging tape for the intended purpose. Different tape materials and adhesives are designed for various applications, such as sealing boxes or securing heavy items. Using the wrong type of tape may result in inadequate sealing or potential hazards. Furthermore, it is crucial to store packaging tape in a safe place away from extreme temperatures, moisture, or direct sunlight. These factors can affect the tape's adhesive properties and compromise its effectiveness. Lastly, when using packaging tape, it is advisable to wear protective gloves if necessary, especially when handling sharp or heavy objects. This can provide an extra layer of safety and prevent any potential injuries. By following these safety precautions, users can effectively utilize packaging tape while minimizing the risk of accidents or harm.

- Q: Does packaging tape come in different odor-free options?

- Yes, packaging tape does come in different odor-free options. Many manufacturers offer packaging tape that is specifically designed to be odorless, making it ideal for sensitive individuals or products that may be affected by strong scents.

- Q: Can packaging tape be used for sealing wooden crates?

- Yes, packaging tape can be used for sealing wooden crates. It provides a strong and secure bond, ensuring that the crate remains sealed during transportation or storage. Packaging tape is designed to adhere to various surfaces, including wood, making it an effective choice for sealing wooden crates. However, it is important to consider the weight and size of the crate before solely relying on packaging tape. For heavier or larger crates, it may be necessary to reinforce the seal with additional methods such as nails or screws.

- Q: Can packaging tape be used for sealing plastic folders?

- Yes, packaging tape can be used for sealing plastic folders. Packaging tape is designed to be strong and adhesive, making it suitable for securing and sealing various materials including plastic folders. It can help keep the contents of the folder secure and protected. However, it is important to ensure that the tape is applied properly and securely to ensure a tight seal. Additionally, it is recommended to use a clear packaging tape that will not obstruct the visibility of the folder's contents.

- Q: Does packaging tape have an expiration date?

- Packaging tape generally lacks an expiration date due to its composition of robust materials like polypropylene or PVC. These substances possess a lengthy shelf life and resist degradation over time. As long as the tape is stored in a cool, dry location, shielded from sunlight and extreme temperatures, it should retain its effectiveness for an extended period. Nevertheless, it is worth noting that the adhesive on packaging tape might lose its stickiness over time, particularly if exposed to heat or moisture. Consequently, although packaging tape may lack an official expiration date, it is advisable to utilize it within a reasonable timeframe to guarantee its adhesive properties remain intact.

- Q: Can packaging tape be used for sealing moving boxes?

- Indeed, when it comes to sealing moving boxes, packaging tape proves to be quite useful. Its design is specifically tailored to secure boxes and packages during transit, boasting durability and strength that ensure a tight seal, preventing boxes from opening or items from spilling out. Moreover, its application is quick and effective, making it an easy-to-use option. It is worth noting that packaging tape often possesses resistance against moisture and can withstand diverse weather conditions, which makes it an ideal choice for long-distance moves or storage purposes. In summary, packaging tape is a dependable solution for sealing moving boxes and guaranteeing the safety of your belongings throughout the moving process.

- Q: Does packaging tape have a specific weight capacity?

- Yes, packaging tape generally does not have a specific weight capacity as it is primarily used for sealing and securing packages rather than providing structural support.

- Q: Can packaging tape be used for sealing medical or laboratory containers?

- Sealing medical or laboratory containers with packaging tape is not advisable. Although packaging tape can temporarily seal general packaging, it is not intended or tested to meet the precise demands of medical or laboratory settings. To maintain airtight and sterile conditions and prevent contamination or tampering, specialized sealing methods are often required for medical and laboratory containers. These methods may involve using adhesive strips, rubber gaskets, or screw caps that are specifically designed for medical or laboratory applications. It is of utmost importance to adhere to the sealing methods and materials recommended by the manufacturer or industry standards to guarantee the integrity and safety of medical or laboratory containers.

- Q: Is packaging tape safe to use on stainless steel?

- Yes, packaging tape is safe to use on stainless steel. Packaging tape is typically made from materials that are not corrosive and will not damage the surface of stainless steel. However, it is always a good idea to test the tape on a small, inconspicuous area of the stainless steel before applying it to the entire surface, especially if the tape will be left on for an extended period of time. Additionally, removing the tape gently and slowly can help prevent any potential damage or residue on the stainless steel.

Send your message to us

Countdown Packaging Tape Masking Film for Car Paint - China Factory Hot

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 30000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords