Maintenance Free High Pressure Gre Composite Pipes with Toxic Resistance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION

1.Pipe Introduction

It is the ideal product for the transportations of the chemicals, drinking water, waste water, waste gas and sewer.

2.Production Range

Any type and specification RPMP of diameter DN400-DN4000 and pressure PN0.25-PN2.5MPa can be produced. Also, we can provide the customized product according to user’s specific requirements.

3.Application

Due to its own advantages, the RPMP is used extensively in the city engineering water supply and drainage, the water supply and the drainage or the recycle water in the electric factory, the waste water treatment, the oil chemical industry and so on.

TECHNICAL DATA

Stiffness | SN3750 | SN5000 | SN10000 | ||||||

Pressure | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 |

400 | 6.1 | 6.1 | 5.9 | 6.7 | 6.7 | 6.4 | 8.1 | 8.1 | 7.87 |

500 | 7.2 | 7.2 | 7.1 | 8 | 8 | 7.7 | 11.4 | 9.6 | 9.4 |

600 | 8.7 | 8.3 | 8.3 | 9.6 | 9.6 | 9.2 | 12.1 | 11.7 | 11 |

700 | 9.7 | 9.7 | 9.4 | 11.2 | 11.2 | 10.4 | 13.8 | 13.2 | 12.5 |

800 | 11.6 | 11.3 | 10.6 | 12.8 | 12.5 | 11.7 | 15.5 | 15 | 14.2 |

900 | 13.4 | 12.5 | 11.7 | 14.8 | 13.8 | 12.9 | 19.3 | 16.4 | 15.8 |

1000 | 14.6 | 13.7 | 13 | 16.2 | 15.1 | 14.4 | 20.7 | 18 | 17.3 |

1100 | 16.1 | 14.9 | 14.2 | 17.9 | 16.5 | 15.6 | 23 | 19.8 | 18.9 |

1200 | 17.2 | 16.1 | 15.4 | 19.6 | 17.9 | 16.9 | 24.7 | 21.5 | 20.6 |

1400 | 20.4 | 18.4 | 17.7 | 22.7 | 20.5 | 19.5 | 29.2 | 24.8 | 23.8 |

1500 | 22 | 19.9 | 18.7 | 24.4 | 22.1 | 20.7 | 31.4 | 26.3 | 25.3 |

1600 | 23.6 | 21.2 | 20 | 26.2 | 23.4 | 22 | 33.7 | 28.2 | 26.9 |

1800 | 26.3 | 23.5 | 22.4 | 29.2 | 26.1 | 24.7 | 36.4 | 31.6 | 30.3 |

2000 | 27.4 | 25.4 | 23.4 | 35 | 32.4 | 29.6 | 44.7 | 37.3 | 36.1 |

2200 | 29.7 | 27.6 | 25.3 | 37.8 | 35.3 | 32.6 | 48.7 | 41.5 | 40.4 |

2400 | 32.6 | 30.3 | 28.4 | 41.8 | 38.8 | 34.6 | 53.4 | 44.6 | 42.8 |

2600 | 36.3 | 33.5 | 31.5 | 45.2 | 40.5 | 35.4 | 55.8 | 47.2 | 45.6 |

2800 | 39.6 | 36.0 | 34 | 49.4 | 45.1 | 42 | 62 | 53 | 51 |

3000 | 41.0 | 38.1 | 36.2 | 52 | 47 | 45.3 | 67 | 58.2 | 54 |

CHARACTERISTICS

1. High anti-corrosion capability, long designed service time of 20 years;

2. Good hydraulic property, smooth inner surface with absolute roughness of 0.01mm, which is far less than that of carbon steel pipe or cast iron pipe;

3. Lightweight and facility to install and transport;

4. High specific intensity and reliable mechanical performance;

5. Low thermo-conductivity and small thermo-stress, which are allowed to be used in various conditions: exposed buried or suspended, in ocean or in deserts, freezing or humid;

6. Less joints and rapid assembly design: According to concrete engineering conditions, there are a several ways of connection designed for clients to choose, which include Adhesive-bonded Plug Joint, Adhesive-bonded End-to-end Joint, Flange Joint, Plug Joint with O-ring Gasket(with key-lock) and Thread Joint etc.

7. Good electrical insulation

8. Not rust, rot or corrode, not permeate, and without consequent pollution;

9. Anti-furring and vermiculate resistance;

10.Flexible design: the pipe can be designed on the shape and function according to its conditions of usage.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

Q1.What's your sample policy?

A:We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost.

Q2.Can you produce according to the samples?

A: Yes, we can produce or modify the products according to your request.

Q3.How do you deliver the goods to my country?

A:We can provide international express, such as DHL, EMS, UPS, FedEx, etc. We select air freight and sea freight upon your requests. Quotations if without mentioning the shipping costs are shipping fee excluded.

Q4.How much does it cost to ship to my country?

A:When you goanna to place an order, please contact us, because different country has different freight.

Q5.How to get the catalogue?

A:please contact us and tell us what you are looking for.

We will try our best to meet customers' demands. Welcome you come here to visit us. We sincerely welcome partners around the world to establish business cooperation with us on the basis of mutual trust, benefit and development.

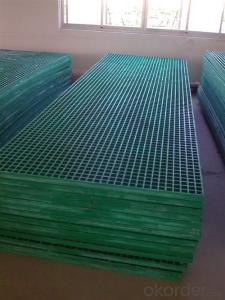

PICTURES

- Q: Designed to support FRP pipes, is it m or mm?

- Glass fiber reinforced plastic cable protection tube chemical composition: GRP winding pipe is a kind of glass fiber reinforced plastic product. With the continuous development of glass fiber reinforced plastic molding technology, FRP products have been widely used in various fields. FRP products have the advantages of light quality, high strength, corrosion resistance, long service life, flame retardant, high temperature resistance and various forms of products. Therefore, the industry gradually increase the use of glass fiber reinforced plastic products, which will be reinforced FRP mechanical properties and molding process put forward higher requirements. The forming process of FRP determines its shape, property and application prospect. The mechanical properties of glass fiber reinforced plastics determine whether their products can be widely used in industries with higher mechanical properties. Fiberglass reinforced plastic square tubes can replace some metal pipes used in industrial and civil fields, such as central air conditioning, chemical plants, etc. but glass fiber reinforced plastic square tube products are not common in the market. This is mainly due to the existence of poor strength, easy deformation and other defects.

- Q: Is the installation of FRP pipes required qualification?

- At present, for purely glass fiber steel, there is no uniform international standards, installation workers must have qualified installation.

- Q: How is FRP ventilation pipe made?

- Solidification strippingThe coated FRP pipe can be released after a period of constant pressure to a certain strength. When the mold is released, the pre - prepared ejection support points shall be removed to separate the mold from the molded air pipe and then to exit the mold. Finally, remove the glass paper on the inside and outside surface. Air duct after stripping. Excess parts or burrs can be polished by hand cutting machine or sand grinder.

- Q: How can I make up the broken glass fiber?

- Don't let the powder go. It is autumn, the temperature is low, so to put more than summer curing agent, as to the exact proportion, I just guess should be: curing agent, accelerator, resin; 1:1.5:8 with glass fiber wrapped around the pipe, coated on the glass fiber cloth to make glass steel with good quickly, let the glass steel the glass fiber cloth fully soaked, waiting for the full glass steel after curing, and then repeated several layers. It will be strong.

- Q: What are the advantages of glass fiber reinforced plastic sand pipe than HDPE pipe?

- Both have their merits, but it depends on their choice!

- Q: How is the glass reinforced septic tank and the cement drain pipe connected?

- Very simple, ah, first install the septic tank, and then drain the pipe ah!

- Q: What are the advantages of FRP pipes?

- Light weight, corrosion resistance, aging resistance, long service life,

- Q: Can FRP pipes be used in heating pipes?

- Glass steel pipe road does not belong to common heating pipe material.Heating pipe requirements are solid, high temperature, pressure, easy connection, convenient construction.Usually, heating pipes are made of steel and materials are more common.

- Q: What are the main points for the installation of FRP ducts?

- Organic pipe basically no sales, mainly too expensive, rather than bad, and now most of them are inorganic pipe, or white iron pipe, there is a kind of polyurethane, but rarely used

- Q: What is the elastic modulus of glass fiber reinforced plastic?

- If so, the modulus of elasticity is 72000MPa, and the glass is isotropic, so the modulus of elasticity in the three directions is the value.

Send your message to us

Maintenance Free High Pressure Gre Composite Pipes with Toxic Resistance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords