Magnesium Alloy Ingot AZ91D High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Magnesium Alloy Ingot

The Mg Metal is a fairly strong, silvery-white, light-weight metal.

Form: ingot

Ingot: (8 ± 0.5) kg / ingot

2.Application

. The high temperature at which magnesium burns makes it a useful tool for starting emergency fires during outdoor recreation. Other related uses include flashlight photography, flares, pyrotechnics and fireworks sparklers.

. To photoengrave plates in the printing industry.

. In the form of turnings or ribbons, to prepare Grignard reagents, which are useful in organic synthesis.

. As an additive agent in conventional propellants and the production of nodular graphite in cast iron.

. As a reducing agent for the production of uranium and other metals from their salts.

. As a sacrificial (galvanic) anode to protect underground tanks, pipelines, buried structures, and water heaters.

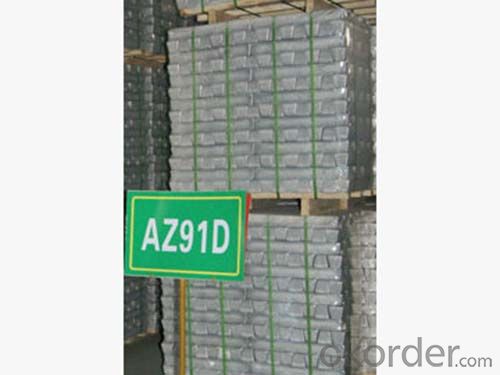

3. Pictures

4. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

CNBM, The Fortune 500. A world class manufacturer & supplier of magnesium ingots, magnesium alloy ingots, magnesium alloys plates&sheets, magnesium alloy bars, Magnesium alloy slabs,magnesium alloy wires,magnesium alloy tubes and etc.. bases in China.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;

We would like to offer free samples for your inspect and check.

We have advanced manufactured equipments,such as hot rolling equipment. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③What is your main markets?

Our main markets are from Europ, America and Aisa. Such as Germany,Czech, Poland, England, Canada, Korea, Turkey etc.

Magnesium is a new type of light in 20th century developed corrosion resistant metal materials, the application of magnesium is concentrated in the magnesium alloy,aluminum alloy production, steelmaking desulfurization, aviation military four areas, are widely used in automobile manufacturing, light industry, metallurgy industry,chemical industry, electronic industry and meter manufacturing, etc.

Excellent performance of magnesium alloy with beautiful posture by the computer, household appliances, mobile phone manufacturers.It with a low specific gravity and large intensity of unit weight, high chemical stability of superior function, makes the aluminum magnesium alloy and its popularity, magnesium die casting magnesium industry get rapid development.

Automobile industry application of magnesium alloy has high strength, heat resistance, abrasion resistance, and the advantages of light weight, make its gradually take the place of cars in the automobile industry of plastic products and the proportion of large steel components, mainly to replace the original engine, steering wheel, seat base and so on.

- Q: Causes of high manganese content in magnesium ingot

- Potassium Permanganate heat decomposition of potassium manganate, manganese dioxide and oxygen, and the quality of solid oxygen generating surplus.

- Q: What is the black powder on the surface of magnesium ingot AM50A?

- These are commonly used in the die casting magnesium alloy brand.

- Q: What are the surface defects of magnesium alloy rolling?

- Because magnesium alloys are made of magnesium ingots, while magnesium ingots contain other elementsTherefore, magnesium alloys are generally used in die castingAluminum alloy is rolled only

- Q: What harm does magnesium alloy have to human body?

- Yes, the alloy is usually aluminum, magnesium, iron and the like, may cause chronic aluminum poisoning, that is, excessive accumulation of aluminum in the body, affecting intelligence and other physical functions.

- Q: What are the generally feasible surface treatment methods for magnesium alloy die castings?

- Your question is difficult to answer, the general casting magnesium alloy surface treatment should be divided into surface coating treatment and surface treatment, although the two are related, but in the process and technology, but there is a big difference, its main features are not the same. Therefore, you must specify the purpose and function of your work before you can tell you the actual surface treatment.

- Q: Why the cost of ferrosilicon production will lead to a rebound in the price of magnesium ingot?

- 75# ferrosilicon in pidgeonmagnesiumprocess often used in high temperature smelting process of magnesium metal, will be replaced from CaO.MgO mg, each ton of magnesium will consume 1.2 tons of ferrosilicon, plays a big role in magnesium production.

- Q: The industrial application of magnesium and the main title and technical difficulty of producing magnesium products with magnesium chloride as raw material

- Magnesium has flammable explosive, high temperature and bright white combustion characteristics, so magnesium powder is widely used in military industry and aerospace industry and other fields of science and technology.

- Q: What are the differences between aluminium magnesium alloy, aluminum alloy and plastic steel?

- An alloy based on aluminum. The main alloying elements are copper, silicon, magnesium, zinc and manganese. The minor alloying elements are nickel, iron, titanium, chromium, lithium and so onAluminum alloy low density, but relatively high strength, close to or higher quality steel, plastic good, can be processed into various profiles, with excellent conductivity, thermal conductivity and corrosion resistance, widely used in industry, the use of only steelAluminum Alloy divided into two categories: cast Aluminum Alloy, cast under; deformation Aluminum Alloy, can withstand the pressure processing, mechanical properties than cast. Aluminum Alloy material can be processed into various forms and specifications. Mainly used in the manufacture of aviation equipment, daily necessities, building doors and windows.

- Q: Will the enterprises that produce sponge titanium use magnesium ingots?

- The essence of magnesium reduction is at 880 DEG ~950 DEG under argon atmosphere, let four titanium chloride and magnesium were obtained by the reaction of sponge titanium and magnesium chloride, magnesium chloride removal in titanium sponge and excess magnesium by vacuum distillation to obtain pure titanium by distilled condensate molten metal recovery magnesium, magnesium chloride by molten salt electrolysis recovery of magnesium and chlorine. The process of producing titanium from refined four titanium chloride is divided into two steps: reduction and distillation. For a long time, reduction and distillation are all step by step, but now they are tending to be combined and large-scale.

- Q: What is magnesium aluminum alloy and what is its use?

- Magnesium alloy molecular formula: Mg4Al3 molecular weight: 178.22 color is brown, the proportion is about 2.15g/cm3, the melting point of 463 DEG C, when combustion temperature reaches 2000 DEG -3000 DEG. In fireworks production process plays a very important role in reducing agent, can also be used as white lighting agent and agent.

Send your message to us

Magnesium Alloy Ingot AZ91D High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords