Magnesium Alloy Ingot AZ91A Mg Alloy Ingot Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Magnesium Alloy Ingot AZ31B Mg Alloy Ingot

General Information

Magnesium Alloy Ingot with a small specific gravity, high intensity , high wear-resisting performance, has some of the corrosion resistance and resistance to radiation performance,good chemical stability against the alkali, mineral , excellent weldability and workability.

Advantage of Magnesium Alloy Ingot

Compared with aluminum and aluminum alloy, the Magnesium Alloy Ingot can take more impact load ability and has so many other superior performance. Magnesium alloy has the good electromagnetic shielding ability, so it is applied in the aerospace, automotive, chemical, electronic and other military industrial and civil industry;

Production Process of Magnesium Alloy Ingot

Adopt the hot rolling process, ensure the product good mechanical properties, refinement of grain structure, high strength and great ductility, etc.

Application of Magnesium Alloy Ingot:

vibration platform, the aerospace industry, denfense industry , automobile industry ,etc.

Size of Magnesium Alloy Ingot:

-Unit Weight:5kg,6kg,7.5kg,8kg,12kg -Grade:AZ31B,AZ91D,AZ61D,AZ63, AM50,AM60

Features

-Competitve price -Annual production capacity 80000MTS

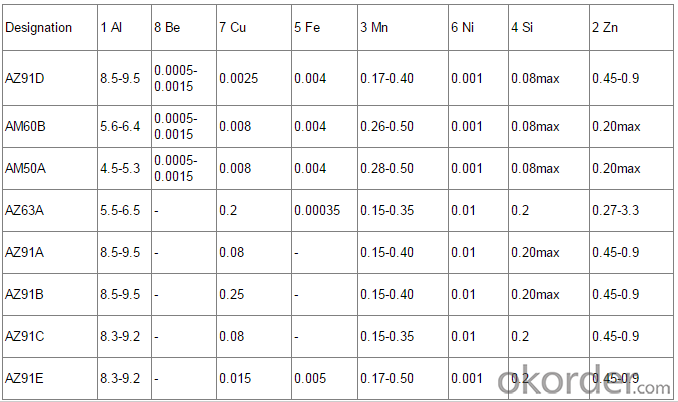

Technical Composition

ASTMB 93/B 93/M-05

Images

Images

- Q: Causes of high manganese content in magnesium ingot

- Potassium Permanganate heat decomposition of potassium manganate, manganese dioxide and oxygen, and the quality of solid oxygen generating surplus.

- Q: What is the black powder on the surface of magnesium ingot AM50A?

- AZ91D, the most widely used magnesium alloy, has high strength and excellent casting performance. It is used in motorcycles, computer parts, housings, and lids

- Q: What are the surface defects of magnesium alloy rolling?

- When the deformation rate is too large, it is easy to cause serious cracking.

- Q: What harm does magnesium alloy have to human body?

- Yes, the alloy is usually aluminum, magnesium, iron and the like, may cause chronic aluminum poisoning, that is, excessive accumulation of aluminum in the body, affecting intelligence and other physical functions.

- Q: What are the generally feasible surface treatment methods for magnesium alloy die castings?

- 1. chromate passivation method, which is the most widely used and the most important method in industry. The so-called chromate passivation solution is metal with chromic acid, chromate or dichromate as a major component of the film on the metal surface to form a compound composed of trivalent chromium and hexavalent chromium and six metal itself, this film has protective passivation metal corrosion inhibition for. The specific passivation process is to dip the magnesium ingot which is intended to be passivated into the passivation solution. At this time, the surface metal is oxidized by the solution, forming metal ions into the solution. Since the solution is acidic, the following reactions occur: 3Mg ten, 2HN03 = 4Mg0, ten H20, ten 2N02. anodic oxidation is a surface treatment method to increase the thickness of base metal oxide film by electrolytic reaction and to improve the film properties. The film has excellent corrosion resistance and abrasion resistance.

- Q: Why the cost of ferrosilicon production will lead to a rebound in the price of magnesium ingot?

- 75# ferrosilicon in pidgeonmagnesiumprocess often used in high temperature smelting process of magnesium metal, will be replaced from CaO.MgO mg, each ton of magnesium will consume 1.2 tons of ferrosilicon, plays a big role in magnesium production.

- Q: The industrial application of magnesium and the main title and technical difficulty of producing magnesium products with magnesium chloride as raw material

- The chemical property of magnesium is active, in the metallurgical industry by using, steel and non-ferrous metal casting, with magnesium as desulfurization agent, cleaning agent, as reducing agent in the production of rare metal. In the chemical industry, magnesium can be used as a dehydrating agent of organic compounds or directly with organic compounds and preparation of magnesium powder. In recent years, in the use of magnesium powder spray, coating, anticorrosion industry is more and more big, the amount of silicon and polysilicon and powder metallurgy die casting is also great.

- Q: What are the differences between aluminium magnesium alloy, aluminum alloy and plastic steel?

- In the fireworks production process plays a very important role in reducing agents, but also as a white light agent and lighting agentMagnesium alloy is magnesium ingots and aluminum ingots in protective gas melted into. For a long time about the structure of Al Mg alloy with two kinds of argument. One theory is that magnesium alloy is a simple physical mixture; another is magnesium alloy changes inside the crystal structure, is not a simple physical mixture.

- Q: Will the enterprises that produce sponge titanium use magnesium ingots?

- Can be used, or can not be, according to process methods and the production of sponge too, one way is to use magnesium reduction method

- Q: What is magnesium aluminum alloy and what is its use?

- Magnesium alloy molecular formula: Mg4Al3 molecular weight: 178.22 color is brown, the proportion is about 2.15g/cm3, the melting point of 463 DEG C, when combustion temperature reaches 2000 DEG -3000 DEG. In fireworks production process plays a very important role in reducing agent, can also be used as white lighting agent and agent.

Send your message to us

Magnesium Alloy Ingot AZ91A Mg Alloy Ingot Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords