Magnesite Alumina Brick with Low Density Alumina Fire Brick ISO Certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 550 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So pls stay cool with our quality.

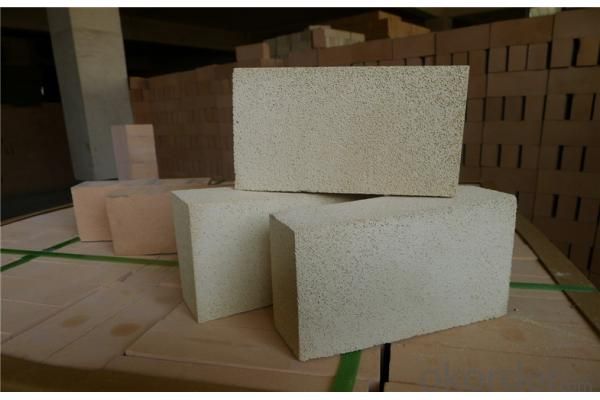

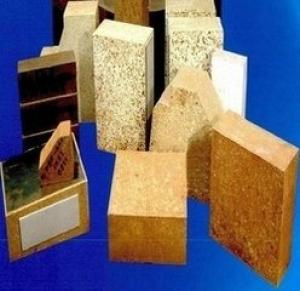

Brief discription for Alumina Fire Brick

CNBM Alumina Fire Brick are classified according to alumina content ranging from 48% to 90%.

CNBM Alumina Fire Brick are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc.

Brief features for Alumina Fire Brick

◆Low thermal conductivity

◆Excellent acid and base slagging resistance

◆High refractoriness

◆Excellent thermal shock resistance

◆Excellent mechanical strength

◆Good spalling resistance and wear resistance.

◆Good corrosion resistance.

◆High-temperature creep rate is quite low.

◆Good volume stability at high temperature.

◆Low bulk density, low thermal conductivity, good thermal insulation performance.

Technical data for high aluminia bricks

ITEM | UAL48 | UAL55 | UAL65 | UAL75 | UAL80 | UAL85 | ALP80 |

Refractoriness, ℃ | 1750 | 1770 | 1790 | 1790 | 1810 | 1810 | 1810 |

Apparent Porosity,% | 22 | 22 | 23 | 23 | 20 | 20 | 18 |

C.C.S, Mpa | 39 | 44 | 49 | 53 | 55 | 60 | 100 |

Refractories Under Load (0.2Mpa),℃ | 1420 | 1470 | 1500 | 1520 | 1500 | 1520 | 1550 |

Reheating Linear Change,% | 1450℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 |

Al2O3 Content , % | 48 | 55 | 65 | 75 | 80 | 85 | 82 |

Why us

1. Strong professional:

Our company has thirty years producing experience in refractory product. Our manager will supervise on a various refractory' s production materials, process control, quality supervision and package delivery, and ensure the products are 100% qualified.

2. Annual supply:

Our company has passed ISO9001 quality management system certification and SGS certification. And the annual supply of shaped and unshaped refractory product is 28, 800-35, 000 tons.

3. Annual exports:

Now we have gained a global sales network reaching Taiwan, Russia, Mongolia, South Korea, vietnam, Pakistan, Bulgaria, Finland, Greece, Spain, Congo, Angola, South Africa, and Maldives, Jordan and so on. The export figure is more than USD 4 million

4. Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

5. Testing equipment;

Our company's testing equipments as follows: :

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester

- Q: Refractory bricks in cement kilns are dangerous wastes

- Silicon Mo brick: good thermal shock resistance, high strength, good wear resistance, suitable for excessive band.

- Q: What are the refractory materials used in casting? Please more details

- Unshaped refractory materials: ramming material, castable, refractory cement, silica, magnesia etc.

Send your message to us

Magnesite Alumina Brick with Low Density Alumina Fire Brick ISO Certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 550 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches