High Quality Magnesite Alumina Magnesia Chrome Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shape: | Material: | |||

| SiO2 Content (%): | MgO Content (%): | CaO Content (%): | |||

| Refractoriness (Degree): | Model Number: | Brand Name: | |||

| Apparent Porosity %: | Cold Crushing Strength Mpa: | Bulk Density g/cm3: | |||

| size: |

Packaging & Delivery

| Packaging Detail: | seaworthy wooden pallet and then polyethylene film is placed over it, finally the package is tied up with strips. |

| Delivery Detail: | 1 to 2 months after receiving the advance payment |

Specifications

Advantages:

1. magnesia chrome brick

2.CCS:60mpa; RUL:1700

3. Excellent erosion resistance

4. Long service life

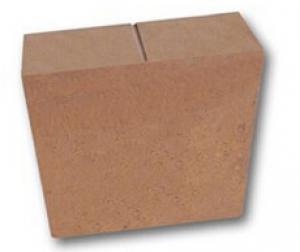

brief introduction of magnesia bricks

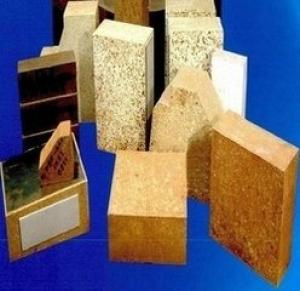

1.The products use fused magnesia as main raw material, after a reasonable size distribution, high pressure forming, high-temperature sintering. The product has strong resistance to slag corrosion ability and high temperature dimensional stability. Mainly used in glass furnace regenerator, the upper part.

2.The regular magnesia bricks are made from dense dead burned magnesia that makes the bricks in good refractoriness, corrosion-resistance, and widely used in checker chamber of glass tank, lime kiln, non-ferrous metallurgical furnaces, open heart furnace, iron mixer and EAF of steel-making, and also ferro-alloy furnace, etc.

3. The bricks with MgO 95% or more in content take the secondary-burning dead burned magnesia or electrofused magnesia as the raw material and bured under the condition of ultra high temperature. They have the features of highly directly bonded and corrosion-resistance and widely used in various kinds of high temperature kilns and furnaces

- Q: Refractory bricks in cement kilns are dangerous wastes

- Magnesia chrome brick: Hang kiln, used for firing zone, the disadvantage is the poor thermal shock resistance, plus six Cr price is highly toxic, the production and use of the national magnesia chrome brick is gradually reduced, the brick production unit as soon as possible to find alternatives.

- Q: What are the refractory materials used in casting? Please more details

- The classification of commonly used refractory materials casting smelting process: refractory brick: Siliceous brick, high alumina brick, corundum brick, magnesia brick, magnesia brick, magnesia brick etc.

Send your message to us

High Quality Magnesite Alumina Magnesia Chrome Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords