Light Weight and High Quality of Whole Aluminum Formwork System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Whole Aluminum Formwork Description

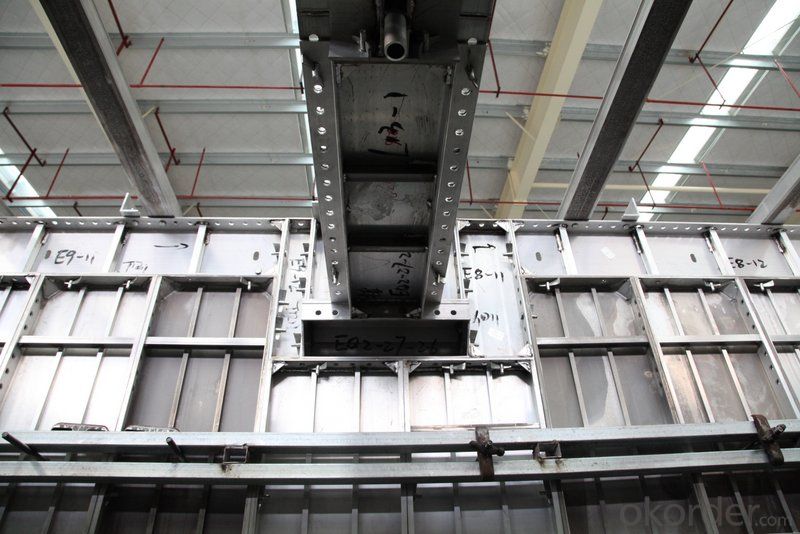

Whole Aluminium Formwork System is designed to reduce material quantity, erection and dismantling time as well as effort, subsequently increasing efficiency and reducing general construction time, materials and labour cost. All main components are manufactured from high grade aluminium alloy. This structural grade aluminium has exceptional properties being extremely light in weight but also heavy-duty and durable. When incorporating this into a design which utilizes standard components and allows several possible plan and elevation variables, it provides a lightweight solution for a large area slab formwork system.

2. Main Features of Whole Aluminum Formwork

-Light and easy assemble

-Simple structure.

-Competitive prices

3. Whole Aluminum Formwork Images

4.Whole Aluminum Formwork Specifications

1: MaximumColumn Size:900 x 900mm

(2’-11.5”x 2’-11.5”)

2: DesignConcrete Pressure: 1,800 psf (90 kN/m2)

3:StandardPanel Width 900mm, 750mm & 600mm

(2’-11.5”,2’-5.5” & 1’-11.5”)

4:StandardPanel Height: 3.0m, 2.4m, 1.2m

5.FAQ of Whole Aluminum Formwork

1) What can we do for you?

We can ensure the quality of the Whole Aluminum Formwork and avoid extra expenses for customers.

We can provide you the professional technical team.

We can provide professional building proposal for your projects.

Please feel free to customize.

2) What promises can be done by us?

If interested in this kind of formwork, please feel free to write us for any QUOTE.

If need any technical and building assistance, we could provide on-site professional staff for instruction.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale services?

Response will be carried out in 24hours after receiving any complain or request.

- Q: Where was the construction machinery conference held in 2015?

- Organizer: China Academy of machinery science and engineering machinery and military modified vehicle testing center, Shandong Bada International Engineering Machinery Company Limited, Shandong Bada Luqiao Construction Co. Ltd. and Shandong northern Luqiao Engineering Company Limited. Organizer: Shandong Bada international engineering machinery City, Lee brothers auction, Beijing Shengda Trade Center, Hing Beijing power machinery and equipment in the international science and Technology Co Ltd

- Q: What are the sectors of machine building and parts processing?

- 3., machinery manufacturing is also a kind of industry, many industries have parts manufacturing, processing links. Therefore, the processing of parts does not belong to a particular industry.

- Q: What are the world famous mechanical equipment exhibition?

- 2 、 Las Vegas Construction Machinery Exhibition (Conexpo-Con/Agg) sponsored by the American equipment manufacturers association, the American precast concrete association, the United States sand association. It is the world's second largest construction machinery exhibition after BAUMA. The exhibition, sponsored by the American Association of equipment manufacturers, has been held every three years for nearly a hundred years. The next exhibition will be held on March 2017 7-11. The exhibition is of great size and numerous merchants. It has focused on world famous brands such as Caterpillar, Komatsu, Liebherr and Volvo. It is an important platform for displaying the latest technology, equipment and products in the industry.

- Q: China mechanical net

- From Chinese GM parts, general machinery, hardware, tools, instruments, electrical appliances and related equipment, textile equipment, chemical equipment, agriculture, food equipment, construction equipment, environmental protection equipment, mining equipment, metallurgical equipment, financial equipment, commercial vehicles and accessories, machinery processing equipment, machinery processing industry machinery enterprises and mechanical products

- Q: Construction machinery production need to deal with what documents?

- The person in charge of the enterprise, the person in charge of the project, full-time safety management personnel in "safety assessment qualified" column content according to the "three persons" Safety Assessment Certificate (fill in the contents of enterprise work safety management staff should meet the enterprise production safety management, the safety management department staff with the qualification to the total contract for not less than 5, not less than 3 professional contracting labor subcontracting, not less than 1; the construction site should be equipped with full-time safety management personnel according to the project size can be determined, according to the construction area of less than 10 thousand M2 project has at least a part-time staff of more than 10 thousand M2; project 1 - 2 full-time staff; more than 50 thousand M2 large sites, according to different professional safety management group);

- Q: Where does Heilongjiang do the most construction machinery?

- All of the industry designated product range is roughly the same as that of China engineering machinery and other countries are also increased the railway engineering machinery, forklifts and industrial handling vehicles, decoration machinery, elevator, pneumatic tools and other industries.

- Q: Mechanical bearings, all types? Roughly

- Spherical roller bearings have two raceways in the inner and outer ring raceways between spherical assembly, a drum shaped roller bearings. The center of curvature of the raceway of the outer race is consistent with the center of the bearing, so it has the same self-aligning function as the self-aligning ball bearing. When the axle and shell are bent, the axial load in two directions can be automatically adjusted. Radial load capacity, suitable for heavy load and impact load. Inner diameter is tapered bore bearings can be installed directly. Or the use of tight sets, the demolition cylinder installed on the cylindrical shaft. The cage uses a steel plate holder, a polyamide forming cage and a copper alloy car holder.

- Q: Where are the hanging baskets for the building?

- It is forbidden to take a stool or put a ladder on a hanging basket to work higher; it is not allowed to work alone in a basket, and no electric machinery or equipment can be placed in the basket;

- Q: What are the sub projects of a construction project?

- Appendix B Construction Engineering Division (sub branch) engineering, sub project division, B.0.1 Construction Engineering Division (sub branch), engineering, sub projects can be divided into table B.0.1. Table B.0.1 division number of construction works, sub works and sub projects

- Q: What functions should be achieved in mechanical structure design?

- The main features of the mechanical structure design are: (1) it is a set of thinking, drawing and calculation (sometimes necessary experiments) in one of the design process, is involved in machinery design, the most specific, the largest volume of work, in the whole process of mechanical design, an average of about 80% of the time for the structure design plays an important role in the success of mechanical design. (2) the multi solution of mechanical structure design, that is, the mechanical structure that satisfies the same design requirement, is not the only one. (3) the mechanical structure design stage is a very active design link, often needs to cross repeatedly. Therefore, in the design of mechanical structure, it is necessary to understand the basic requirements of the mechanical structure from the whole of the machine

Send your message to us

Light Weight and High Quality of Whole Aluminum Formwork System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords