Latest Style Composite Tank - No Toxic FRP Tanks and Vessels Machine Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

INSTRUCTION

FRP tanks and vessels can be largely used in many areas of the light industry, petroleum, chemical, food brewing, transportation and so on. Such product can resist the corrosion of various acids, alkalis and salts.

CHARACTERISTICS

• High mechanical strength

• High mechanical inertness

• Resistance to weathering

• Low thermal and electrical conductivity

• Long Life

• Non-toxicity

• No need for maintenance

• Light weight

DESIGN PHILOSOPHY

The correct structuring of any kind of G.R.P. tank consist of three distinct types of layers:

• Chemical Resistant Layer

• Mechanically Resistant Layer

• Outer Protective Layer

OTHER DESIGN CONDITIONS

• Working pressure, Vacuum

• Support span

• Working temperature

PRODUCTION RANGE

FRP small-scale storage tank: Diameter ≤ 4M

Large-scale jobsite winding vertical storage tank: Diameter 4200mm-25000mm

EXECUTIVE STANDARD

FRP small-scale storage tank

JC/T587-1995 (Glass fiber reinforced plastic storage tank)

Large-scale storage tank

HG/T3983-2007 Industry standards of Chemical Corrosion-resistant jobsite Winding FRP Large-scale storage tank

HG/T20696 Design Requirements of FRP Chemical Equipment

COMPANY INTRODUCTION

CNBM, China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies

.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products, professional service and complete solution to our customers. Strong delivery capacity, advanced technology

& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

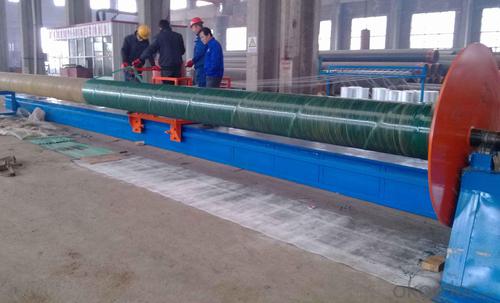

PICTURE S

FAQ:

1)Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world.

2)Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly

3) Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications.

4) Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit. If you check with okorder, you will see that we have never got any complaint from our customers.

- Q: How to make the glass fiber reinforced plastic sealing head?

- Resin glue mixed with curing agent, the time hardened by dry process is not long. After checking it well, it can be opened, because the model has a plastic film at the bottom, so it's very nice to remove it. Remove the excess burrs with a manual cutting machine and make them look like pictures.

- Q: What are the manufacturers of glass fibre reinforced plastic storage tanks in Guangdong?

- They have always adhered to the concept of technological innovation, service and caring, bringing the company to a whole new height. Their business philosophy has become an object of imitation for many companies.

- Q: What type of resin is used in FRP tanks for electroplating waste water?

- Glass fiber is made from glass, and the main component of glass fiber is silica. The glass fiber is the molten glass into uniform quality 0.5-30 microns in diameter of the filaments, with no burning, corrosion resistance, high tensile strength, good optical performance, low price and easy to get raw material, so it is excellent reinforcing material.

- Q: Does anyone know the wall thickness of 10m3 FRP tanks?

- Conventional tank 1 cubic is 7mm.10 cubic, is 8mm. The 50 cubic is 10mm. Tanks can be customized according to the thickness you need.

- Q: What are the points for attention in the process of making FRP tanks?

- More complicated, to moulding, demoulding, polishing, coating on artificial adhesive coating, cloth, dry film, trimming, grinding, etc.

- Q: How can we produce qualified FRP tanks?

- Glass fiber reinforced plastic storage tank should first consider what he is used to store, and then the winding process of glass fiber reinforced plastic storage tanks, now generally winding, the intensity will be much better than the long hand process!

- Q: How heavy is a 200 cubic winding GRP tank?

- Tank surface area * tank thickness * weight (GRP specific gravity 1.8) = tank weight

- Q: FRP tank what is impermeable layer?

- As a part of the tank wall, part from the function, lining layer, structure layer and the surface layer, the inner layer function is to solve the corrosion and leakage prevention role.

- Q: Can FRP tanks withstand industrial hydrochloric acid?

- Resistance, concentration of industrial hydrochloric acid is generally 30%, you can use the common resin.

- Q: Are there any design standards for FRP tanks?

- The glass fiber reinforced plastic storage tank produced by Yi Yuan glass fiber reinforced plastic carries out JC/T587 - 95 "fiber winding reinforced plastic storage tank", HG/T20696 - 1999 regulations for the design of FRP chemical equipment, and HG/T20640 - 1997 "plastic equipment" standard. Can be widely used in petroleum, chemical industry, light industry, food brewing and other fields, corrosion resistant to all kinds of acid, alkali, salt and organic solvent. By selecting different materials, which can be designed to make full use of material properties, according to the use of various different tank design, effectively play the strengths of various materials to achieve reasonable timber to meet customer requirements.

Send your message to us

Latest Style Composite Tank - No Toxic FRP Tanks and Vessels Machine Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords