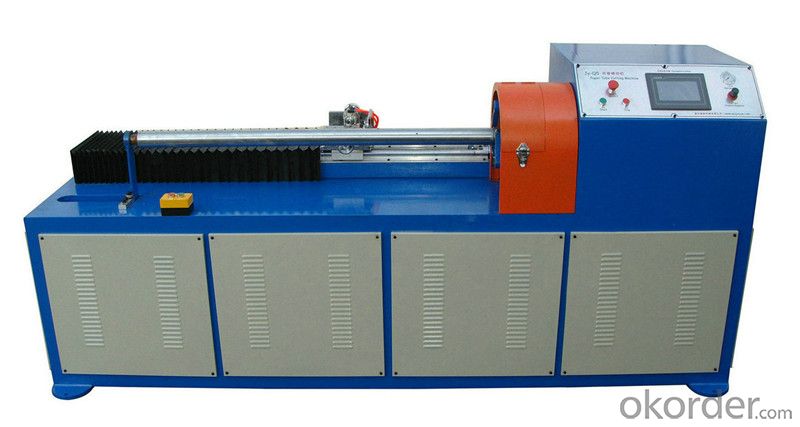

Large Quantity Paper Tube Cutting Machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Description

Large Quantity Paper Tube Cutting Machine

2.Main Features

1. Each cut need just 0.5s. (need to change for the different thickness );

2. Circuit adopt import plc programmable logic controller control, and color touch-screen operation;

3. With automatic off, automatic folder management, automatic shutdown;

4. Stable performance, fully automatic production ,system self-diagnostics and warning;

5. Positioning servo systems, precision ball screw drive, cutting the resolution up to 0.01mm

3. Images

4. Specifications

Large Quantity Paper Tube Cutting Machine technical parameter

Technical Parameter | |||

Tube length | 10-1500 mm | PLC controller | Delta |

Tube diameter | 50-200 mm | Touch screen | MCGS |

Tube wall-thickness | 1-20 mm | Executive part | CHINT |

Knife quantity | 1 | Signal part | Omron |

Cutting way | Tube rotate only | Pneumatic part | AIRTAC |

Load and unload | manual | Main motor | 2.2 KW |

Feeding way | Pneumatic | Mobile screw | Taiwan |

Operator | 1 person | Move track | Taiwan |

Speed control | Transducer | knife | 2 |

Mainframe size | 2800*750*1300 mm | Useful tool | 1 set |

Weight | 800 KG | ||

5. FAQ

- Do you offer after sale service? How long the service will last?

Sure, we offer one year after sale service for free if quality problem.

- Is your factory or trading company?

We are producer, a state- owned enterprise.

- Q: What are the main functions of packaging machinery?

- Eight main functions of packaging machinery and equipmentPacking is a necessary condition for products to enter the circulation field

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- A small object, small particle, powder, crystal, liquid, suitable for packing

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- Is it settled?. Not really! It is not recommended to use torque as parameter control here. This is a tricky amount of control. And easy to fluctuate, prone to misoperation

- Q: What kind of reducer is commonly used in packaging machinery?

- Generally speaking, gear reducer, planetary gear reducer, and the most common one, these equipment power is relatively small, and some need to take the brakes of the motor reducer

- Q: Working principle of packing machine

- In the first step, the wrapping paper is pulled down by a bag pulling motor, and then the paper part is supplied with paper according to the signal of the paper feeding sensor, and the wrapping paper is formed through the forming part of the shaper

- Q: What is the delay time of the packer's cross sealing?

- You can debug it yourself, set up a parameter, such as a delay of 1 second or a few seconds, look at the action of sealing, you know what time it is.

- Q: Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;But to use the hot pressing machine there is to do bakelite mold. Our company specializing in the production of blister, in addition to help customers hot packaging, directly to the finished products to customers

- Q: What's the fastest packing machine?

- 3 ideal speed of the package can reach 70 packs, that is, 70*3 = 210., and now there are 4 packages abroad. But the bags are small.

- Q: What are the packaging machines that use temperature control watches?

- A lot of heating machines have to use thermostat

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Molding: mainly used for thermosetting resins. There is a special molding machine. Molding pressure is much greater than the above. The mold structure is also more complex.

Send your message to us

Large Quantity Paper Tube Cutting Machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords