JM-HF High Performance Grout Admixture

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

JM-HF High Performance Grout Admixture

DESCREPTION

JM-HF (Low-bleeding & Minor-expanding) High Performance Grout Admixture is a mineral-based composite incorporated with functional polymer. It has the multi-function of water reducing effect, strengthening effect, slump retention ability, minor-expansion and low-bleeding etc. The addition of JM-HF induces moderate expansion to compensate the shrinkage throughout the hydration course of the cement as well as increase the fluidity of the grout to a large extent at low water to cement ratio. Moreover, the addition of JM-HF effectively reduces the bleeding rate and resolves the contradiction between the fluidity and the segregation in the cement or concrete mixture system with multi-phase, different constitution and heterogenous character. It can be used for the construction of cement or concrete grout and is in particular adaptable to the grout of post-tensioned prestressed concrete structure.

MAIN TECHNICAL INDEXES AND PROPERTIES

High water reduction and strengthening effect

The water reduction of JM-HF is above 25%. The grout prepared with JM-HF has high fluidity with

Ma-cone flow time of 14-25s and is easy for pouring. The fresh paste can freely fill into and achieve

self-compaction even for very complex-structured part.

Low bleeding rate

The addition of JM-HF effectively lowers the bleeding rate of the grout. With the function of the polymer, the viscosity of the grout is moderately increased to avoid sedimentation and prevent defect due to transportation

of the water to the surface of the paste while the grout still retains high fluidity. The addition of 13% JM-HF can reduce the bleeding rate of the grout to 0.

Minor-expansion

The addition of JM-HF can induce moderate expansion at different stages of the hydration and hardening of the cement to compensate the plastic shrinkage, self-desiccation shrinkage as well as drying shrinkage of the grout. The grout with JM-HF has no shrinkage and expansion<1% at the early 28d autogenous shrinkage<2×10-4, which ensures the

volume stability of the grout.Moderate set retarding effect and good slump retention ability

In order to ensure the construction time of grouting, the retarder in JM-HF can be adjusted according to the change of the season to satisfy the requirement of the construction in different seasons.

Safety

Nontoxic, non- irritative and non-emissive, and no corrosive substance to the steel bar. The pH value of

JM-HF is 7.0 and chloride ion content is 0.03%.

METHODS OF USE AND ATTENTIONS

● The cement should be qualified and have no wetting and blocking. It is best to adopt Portland cement.

● The tentative tests should be conducted beforehand to achieve the best mix proportion. The normal addition rate of JM-HF is 10-20%(replacing cement by weight) and the advisable water to powder ratio is 0.35-0.37.

● Ensure accurate measurement and choose high-quality mixer. It is recommended to prolong the blending time a little to ensure well distribution.

● Pay attention to avoid wetting and direct sunshine. The shelf-life is one year.

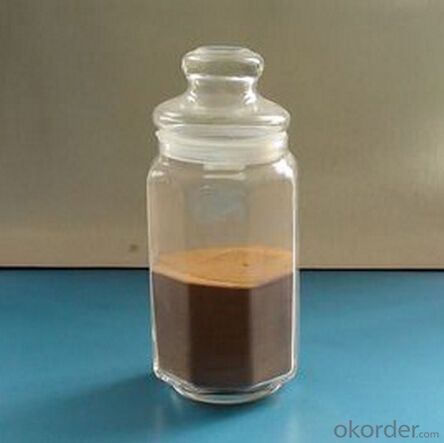

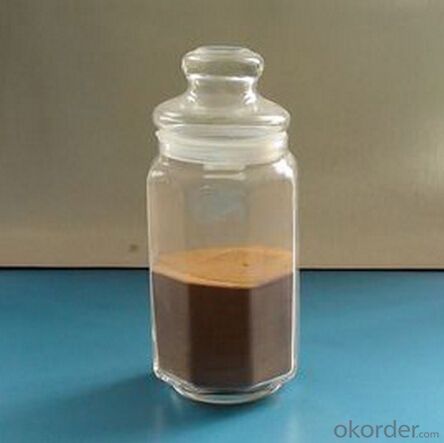

PACKING

JM-HF (Low-bleeding & minor-expanding) High Performance Grout Admixture is stored in anti-wetting double-layer plastic bag and has neat weight of 40kg per bag. It’s very easy for transportation.

AFTER-SALE SERVICES

To assist you in obtaining predicated performances, ensure high quality projects, and improve technical level, we offer technical consulting service, site mix proportion design or advising mix proportion. Our technical personnel would give free-charge site assistance service as well as construction technical guide. We conduct consistent services of sale of new products and spreading of new technology.

UNIFORMITY PARAMETERS

● Fineness: Residue on 0.315mm mesh sieve: ≤8.0%.

● Water content: ≤6.0%

● MgO content: ≤5.0%.

● Chloride ion content: ≤0.05%

● pH Value: 7±1.0

SCOPE OF APPLICATIONS

The product can be widely used for cement or concrete grout materials. It is in particularly adaptable to the grout of construction of post-tensioned prestressed concrete structures for large scale project such as high way, bridge and nuclear power plant.

Send your message to us

JM-HF High Performance Grout Admixture

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords