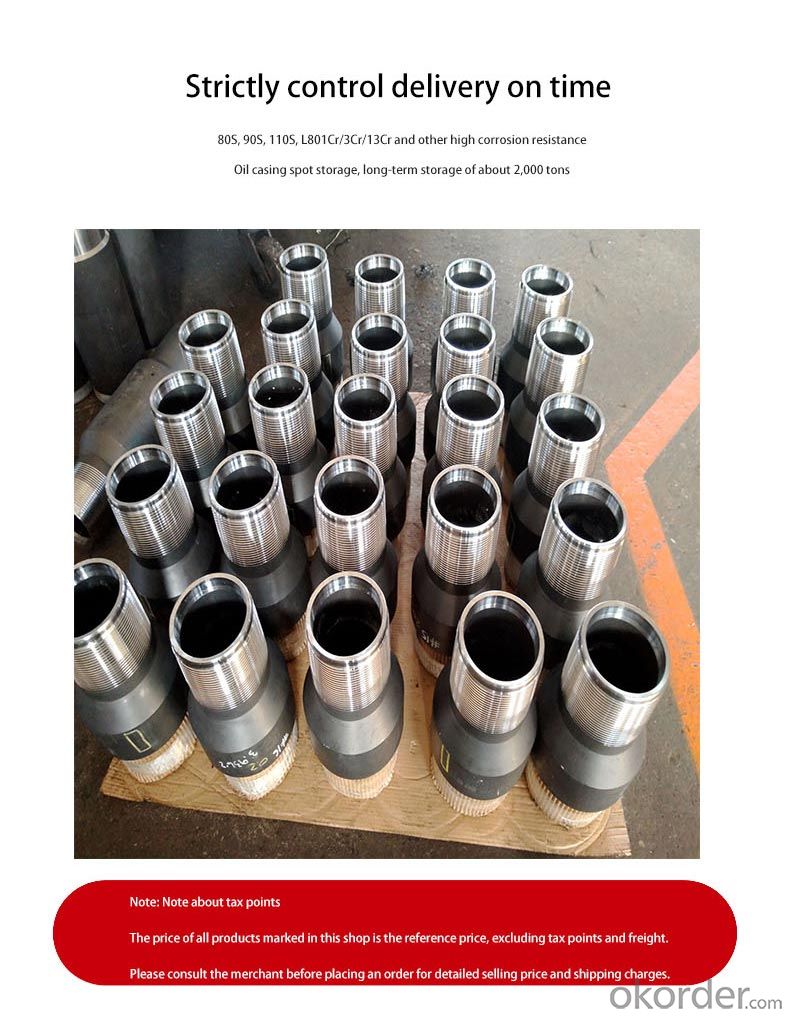

J55-P110 Grade Longkailai Couplings, Spot Supply, Strong Sealing, Affordable Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

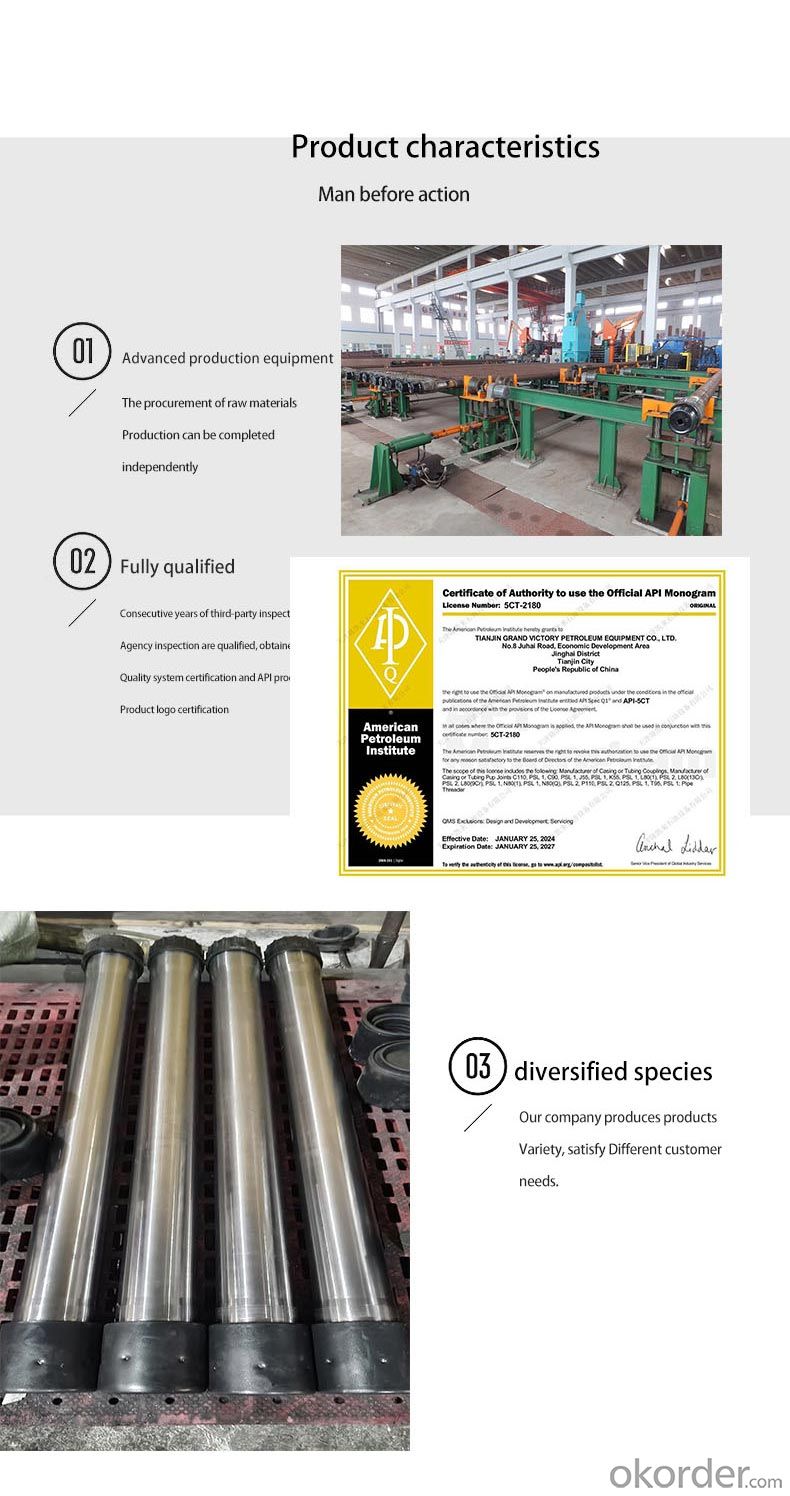

API 5CT J55/N80/P110 OCTG Casing & Tubing Manufacturer Direct

Comprehensive OCTG Solutions for Every Well Profile

As an API-licensed manufacturer, we eliminate intermediaries to deliver J55/N80/P110 casing and tubing with 15% cost savings. Our vertically integrated production process ensures full traceability from steel billet to finished product.

Technical Specifications

Material Science:

J55: 0.45% Mn, 0.25% C composition for shallow wells (≤8,000ft TVD)

N80: Quenched & tempered microstructure withstands 12,000psi collapse pressure

P110: 110ksi SMYS with Charpy V-notch impact ≥45J at -20°C

Threading Technology:

CNC-machined API LTC/BTC threads with ±0.003" pitch diameter tolerance

Optional VAM TOP connections for HPHT wells

Quality Assurance:

100% ultrasonic testing (UT) for laminations

Hydrostatic tested to 80% of yield strength

Applications

J55: Water injection wells, surface casing

N80: Intermediate casing in sour gas fields

P110: Production casing in 15,000psi reservoirs

Case Study

A Permian Basin operator reduced casing costs by 18% using our direct-shipment P110 casing for 35 horizontal wells, achieving 95% torque-turn compliance during running

- Q: What are the safety regulations for working with steel pipes?

- The safety regulations for working with steel pipes may vary depending on the specific circumstances and location, but some common safety measures include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots, ensuring proper handling techniques to prevent injuries, using proper lifting equipment to prevent strain or back injuries, implementing proper ventilation and respiratory protection when working in confined or poorly ventilated spaces, and following proper procedures for welding, cutting, or bending steel pipes to minimize the risk of fire or explosions. It is essential to consult and adhere to local safety regulations and guidelines to ensure a safe working environment when dealing with steel pipes.

- Q: How do steel pipes compare to other materials, such as PVC or copper?

- Steel pipes have several advantages over other materials such as PVC or copper. Firstly, steel pipes are incredibly durable and strong, making them suitable for heavy-duty applications and high-pressure environments. Additionally, steel pipes have a longer lifespan compared to PVC or copper, as they are less prone to cracking, corrosion, or degradation. Steel pipes also provide better fire resistance and are more resistant to extreme temperatures. However, steel pipes can be more expensive and require professional installation due to their weight and rigidity. PVC pipes, on the other hand, are lightweight, affordable, and easy to install, but they may not be as durable or suitable for certain applications. Copper pipes offer excellent corrosion resistance and are commonly used for water supply systems, but they can be more expensive and require skilled labor to install. Ultimately, the choice between steel, PVC, or copper pipes depends on the specific requirements of the project and the desired balance of cost, durability, and performance.

- Q: How are steel pipes used in the manufacturing sector?

- Steel pipes are widely used in the manufacturing sector for various purposes such as transporting fluids, gases, and solid materials, as well as providing structural support in buildings and machinery. They are commonly used in industries like oil and gas, construction, automotive, and manufacturing plants for their durability, strength, and resistance to corrosion. Steel pipes enable efficient and reliable transportation of materials, facilitating the manufacturing process and ensuring the smooth operation of industrial systems.

- Q: What are the different methods of transporting steel pipes?

- There are several methods of transporting steel pipes, including by truck, rail, ship, and pipeline. Each method has its advantages and is chosen based on factors such as distance, cost, and accessibility. Trucks are commonly used for shorter distances or when the delivery location is not easily accessible by other means. Rail transport is efficient for long distances and can handle large quantities of steel pipes. Shipping by sea is ideal for international shipments or when the destination is located near a port. Lastly, pipelines are used for transporting steel pipes for oil and gas industries, as they provide a direct and continuous flow.

- Q: Can steel pipes be used for geothermal energy systems?

- Yes, steel pipes can be used for geothermal energy systems. Steel pipes are commonly used in geothermal installations due to their durability, strength, and resistance to corrosion. They can efficiently transport geothermal fluids, such as hot water or steam, from the geothermal source to the surface for energy extraction or for heating and cooling applications.

- Q: What is the typical length of a steel pipe?

- The typical length of a steel pipe can vary depending on its purpose and application. However, standard lengths for steel pipes often range from 20 feet to 40 feet.

- Q: What is the average lead time for manufacturing steel pipes?

- The average lead time for manufacturing steel pipes can vary depending on various factors such as size, complexity, and quantity. However, a typical range for lead time is generally around 4 to 8 weeks.

- Q: What are the different types of steel pipe valves?

- Various industries and applications commonly utilize several types of steel pipe valves. Here, we present some of the most frequently used types: 1. Gate valves: These valves control fluid flow by raising or lowering a gate or wedge that obstructs the flow path. They ensure a tight seal when closed and are prevalent in applications requiring complete shut-off or full flow. 2. Globe valves: With a globe-shaped body and a movable plug or disc, these valves regulate fluid flow. They excel in throttling capabilities and find application in situations demanding precise flow control. 3. Ball valves: Fluid flow is managed by a rotating ball with a hole in these valves. Alignment of the hole with the pipe signifies full openness, while a perpendicular hole indicates closure. Ball valves are durable, reliable, and extensively used in swift and effortless shut-off applications. 4. Check valves: These valves allow fluid flow in only one direction, preventing backflow. They are instrumental in safeguarding pumps, compressors, and other equipment from reverse flow-induced damage. 5. Butterfly valves: Butterfly valves feature a rotating disc within the pipe to control fluid flow. They are lightweight, compact, and provide rapid shut-off. Butterfly valves are commonly employed in large-scale applications like water treatment and HVAC systems. 6. Plug valves: By utilizing a cylindrical or conical plug, plug valves regulate flow within the valve body. Their simple design, ease of operation, and dependable shut-off capabilities make them prevalent in applications requiring frequent operation and high pressure ratings. 7. Diaphragm valves: These valves employ a flexible diaphragm to manage fluid flow. Pressing the diaphragm against the valve seat blocks flow, while lifting it allows flow. Diaphragm valves are frequently used in environments requiring sterility or hygiene. These examples illustrate the variety of steel pipe valves available in the market. The choice of valve depends on specific requirements, including flow rate, pressure, temperature, and the nature of the transported fluid.

- Q: Can steel pipes be used for underground sewer lines?

- Yes, steel pipes can be used for underground sewer lines.

- Q: How seamless steel tube is formed?

- Hot drawing or cold drawing. The so-called cold is the billet from the thick wall tube is not heated, oil lubrication, with a steel sleeve inside, gradually elongated. Hot drawing is to make the billet tube red, do such work, generally thick wall applicable.

Send your message to us

J55-P110 Grade Longkailai Couplings, Spot Supply, Strong Sealing, Affordable Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords