HSLJ High Speed Bag-on-roll Making Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We have a large-scale, independent research and development and sales of specialty plastic packaging machinery.

The company mainly produces bag making machine, glove machine, film blowing machines, printing presses, granulators and so full of plastic packaging machinery and equipment, products exported to South America, North America, Southeast Asia, Middle East, Africa, Scandinavia and other countries, much favored by the market and praised by users.

NO: 2014714112150

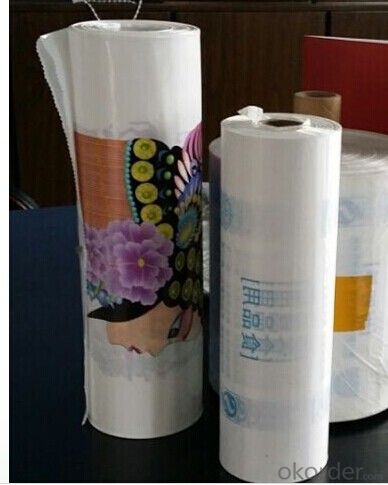

Name: HSLJ-450X2 Double-line High Speed Bag-on-roll Making Machine

1 this machine for the production (with printed or blank) rolling bag design, can produce octagonal bags, garbage bags, fruit and vegetable bags and tablecloths bags.

2 using two servo motors and four variable frequency motor synchronous operation, to ensure stable operation speed and bag. 4 PEC correction device to ensure smooth rewinding.

3 points off the seal in the same position, no tension design.

4 can handle 0.005-0.05mm thickness high density polyethylene (HDPE) and low density polyethylene (LDPE) material film.

NO: 201487163749

Name: T-shirt Bag on Roll Making Machine HSR-500/600700/800

Machine Data:

Model | HSR-500 | HSR-600 | HSR-700 | HSR-800 |

Max. Bag Width | 450mm | 550mm | 650mm | 750mm |

Max. Bag Length | 1200mm | 1200mm | 1200mm | 1200mm |

Film thickness | 0.008-0.10mm | 0.008-0.10mm | 0.008-0.10mm | 0.008-0.10mm |

Bag Making Speed | 40-120pcs/min | 40-120pcs/min | 40-120pcs/min | 40-120pcs/min |

Main Power | 1.1kw | 1.1kw | 1.5kw | 1.5kw |

Machine Dimension | 3.3*1.1*1.5m | 3.3*1.2*1.5m | 3.3*1.3*1.5m | 3.3*1.4*1.5m |

Machine Weight | 850kg | 900kg | 1000kg | 1800kg |

- Q: What are the main functions of packaging machinery?

- Eight main functions of packaging machinery and equipmentPacking is a necessary condition for products to enter the circulation field

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- Change a new one, in fact, the knife is very simple, and the ordinary knife is very cheap.If you don't understand, you can ask me

- Q: Color code positioning of packaging machinery

- The use of the printed color packaging materials, photoelectric switch (available on the color electric eye tracking and positioning), through the control system to drive the stepper motor rotation and color according to the distance between the automatic stop, to complete and accurate packaging products logo.

- Q: The role of packaging equipment in packaging equipment

- Packaging is the necessary condition for products to enter the circulation field, and the main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging equipment is playing a more and more important role in the field of packaging. The main functions of packaging equipment are as follows:

- Q: Working principle of packing machine

- In the first step, the wrapping paper is pulled down by a bag pulling motor, and then the paper part is supplied with paper according to the signal of the paper feeding sensor, and the wrapping paper is formed through the forming part of the shaper

- Q: How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- Ceramic wall and floor tile is a special term used in building ceramics industry. It refers to the ceramic tile used for paving internal walls, exterior walls and floors.It includes:Glazed tiles: white glazed tile, colored shaddock tile, embossed glazed tile, mottled glazed tile, patterned glazed tile, mural glazed tile.Floor tile: paving brick, red floor tile, ceramic mosaic tile (ceramic mosaic), ladder brick.The exterior wall tiles, glazed tiles, glazed tiles, imitation brick, brick from #.

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- If automated packaging, it depends on the factory situation, should not be from the user groups to start. If a small class of cosmetics do, then he will not say to buy a more than ten thousand or hundreds of thousands of automated equipment to pack ah. Automatic packing machine is certainly need a certain amount, a certain basis will be needed, or buy a mechanical automation a month the amount of packaging takes less than one hour, then buy this station automation machinery to do what? So, according to the automatic device, we can not start from the user groups, should be considered from the size of the factory.

- Q: What are the packaging machines that use temperature control watches?

- Direct heating sealing machine, blister packing machine, plastic sealing machine, heating pot, oven, toaster and so on

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- Ha ha, as you say, TV factories are closed down, every household has a TV, but every day there will be a lot of people buy tv.

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

HSLJ High Speed Bag-on-roll Making Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords