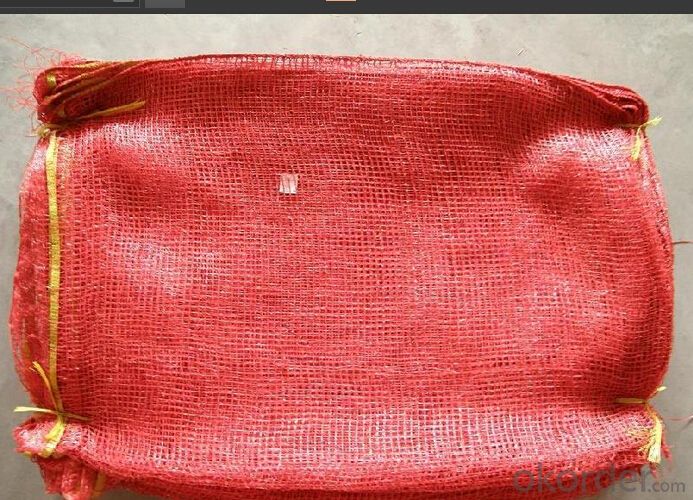

Hot Sale Woven Bag by Polypropylene or Polyester

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Specification of Woven Bag

Name:Woven Bag

Raw Material:100% pp or as the customers' requirement

Color:nature color or as the customers' requirement

Printing:On side or both sides in multi-colors

Width:From 260-750mm

Weave:10x10,12x12,can be customized

Denier: 700D to 1000D

Weight/m2:60gm to 105gm

Treat:UV treated or as the customers' requirement

Sealing:Single/double fold saw bottom

Liner:coated or with liner bag for moisture proof

2,Package of Woven Bag

500pcs/bundle(bale),1000pcs/bundle(bale) or as the customized

3, Application of Woven Bag

To load rice, flour, sugar, fertilizer, sand, cement and so on

4, Images of the Fiber

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of PP related product that used as the raw material of textile, automotive interior and constuction projects and finished product, such as PP woven bag etc. Have been in this field for many years, with rich experience.

2> What's the MOQ?

1x20'GP or1x40'HQ will be better as the price would be economical based on full container load.

3>How long can we receive the product after purchase?

It takes about 1 to 2 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: What is the density of polyester?

- Polyester fiber is an important variety of synthetic fiber, and it is the commodity name of polyester fiber in our country. It is a pure terephthalic acid (PTA) or terephthalic acid methyl ester two (DMT) and ethylene glycol (EG) as a fiber polymer, polyethylene terephthalate as raw materials by esterification or transesterification and polycondensation prepared (PET), the spinning and postprocessing fibers.

- Q: Can half water fiber white gypsum powder be used as plaster mould?

- Half water gypsum and water ratio of about 3 to 2, is to add cold water gypsum, stirring, and then the gypsum slurry into your mold, generally in 5 to 7 minutes to complete the preliminary setting, is formed, and then one day you can dry.

- Q: Is the shirt pure cotton or cotton mixed with polyester?

- Cotton and polyester blended shirt, indeed more crisp, easier to manage, but not easy to wrinkle, but personal comfort will be greatly inferior to cotton clothes. Especially for you, polyester fiber (polyester) is higher in content than cotton. If your skin is more sensitive, but it is next to wear a shirt (do not wear bottoming), it is recommended to buy cotton well.

- Q: Jade LeBron amplification check: what is the meaning of ah granular fiber structure

- Jade LeBron enlarge inspection usually has three kinds of test results: granular column fiber structure, granular and fiber structure, fiber weaving structure. The crystals of jadeite jade are the most granular, granular, fibrous and interwoven structures, which are the most important items for observing the physical composition of jadeite.

- Q: 100% does polyester fiber stretch?

- The strength and elasticity of polyester fiber polyester fiber has the advantages of high recovery capability, so the fastness and durability, anti crease. It's good lightfastness, other than acrylic difference, the light is more powerful than natural fiber fabric, especially in the glass behind the light ability is very good, almost be roughly the same with acrylic. In addition, polyester fabrics resistant to a variety of chemicals, good performance, acid and alkali damage to them are not large, while not afraid of mildew, but also not afraid of moth eaten.

- Q: The difference between polyester fabric and polyester fabric. That kind?

- Polyester fiber synthetic fiber polyester (polyester fibre) by organic acid and diol which is prepared by spinning the. A large number of industrially produced polyester fibers are made from polyethylene terephthalate, a Chinese product called polyester. It is the largest variety of synthetic fiber at present.Polyester is polyester fiber, translation is different

- Q: Is summer shorts good for polyester or pure cotton?

- Polyester fiber is not easy to deformation, pure cotton breathable comfortable, it depends on the type of shorts and your preferences, and everyday wear, then recommend pure cotton

- Q: What material is microfiber shoe?

- Superfine fiber is widely used: use it as a fabric, the sand washing, sanding and other advanced finishing surface to form a layer of similar peach skin hair appearance, and extremely loose and soft, smooth, made of this fabric, high-grade fashion jacket, T-shirt, underwear, and other cool and comfortable skirt sweat, stickless, full of youthful beauty; foreign made with microfiber senior suede, both like leather appearance, texture, style, and low price; the superfine fiber thin and soft, use it to make an excellent decontamination effect can wipe clean cloth, all kinds of glasses, video equipment, precision the instrument, on the mirror without damage; using superfine fiber can be made into a super high density fabric surface is very smooth, used for skiing, skating, swimming and other sports clothing can reduce the resistance, help the athletes to create a good performance; in addition Superfine fiber can also be used in many fields such as filtration, medical treatment, labor protection and so on.

- Q: What's the acid and alkaline difference between wool and cellulose fiber?

- Cellulose fiber is cotton, resistant to alkali, caustic soda, high concentration of mercerizing, PH to 14, nothing, but strength, crystallinity will increase some. But not acid, sulfuric acid will be carbonized

- Q: What is the designated outer fiber?

- The fiber especially in heat resistance and chemical resistance than that of spandex fiber, so you can consider developing spandex fiber due to physical reasons and is not involved in the application.The company uses DOW's new polymer based on its original original polymer and combines its own yarn making technology into production. The basic patent belongs to DOW corporation.

Send your message to us

Hot Sale Woven Bag by Polypropylene or Polyester

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches