High Temperature Density Ceramic Fiber Bulk

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | HP (High Pure) | Application: | Refractory | Thickness: | 10/20/25/30/50mm |

| Width: | 610/1220mm | Length: | 7200/5800/3600/3000mm | Chemical Composition: | Al2O3 46%,Aluminium Silicate |

| Ultimate Strength (≥ MPa): | 0.08-0.12Mpa | Working Temperature: | 950°C-1350°C | Fiber Diameter: | 3-5μm |

| Shrinkage (1800 ℉, 3h): | ≤-3(24 hours) | Thermal Conductivity: | 0.09-0.16w/m.k(400-800C) | Density (kg/m³ ): | 128 |

| Model Number: | JQ | Brand Name: | Place of Origin: | (Mainland) | |

| Color: | Pure White | Density: | 96/128/160kg/cm3 | Certificate: | MSDS |

| Fe2O3 content(%): | 0.4% | Package: | Carton |

Packaging & Delivery

| Packaging Detail: | Package:Carton Carton size:460*460*620mm |

| Delivery Detail: | Within two weeks |

Specifications

1:JQ ceramic fiber blanket

2:Density :96/128/160kg/cm3

3:Working temperature :950-1350 degree

4:MSDS certificate

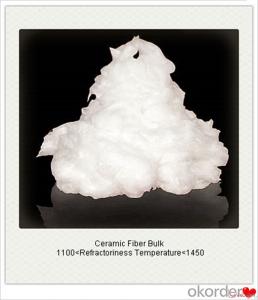

Ceramic Fiber Bulk

Production Technology

Blown-fiber blanket, made of common, high pure, high aluminium and zirconium alumina silicate fiber bulk produced by blowing fiber forming technology, has undergone several processes including needling, thermal forming, vertical and transverse slitting and rolling. In addition to the same excellent performance of corresponding bulk aluminum silicate fiber bulk, various kinds of needled blankets have solid tensile strength.

- Q: What are the main differences between an ordinary furnace and a ceramic fiber furnace?

- Service life: ordinary furnace quenching, sudden heat, easy to cause blasting chamber or cracking, shorten service life, ceramic fiber furnace without blasting chamber or crack possible.There are two common practices in ceramic fiber furnaces:The first is a larger furnace, which is fixed on the furnace wall with ceramic fiber modules;The second is a small furnace, the manufacture of abrasives, direct pouring, or with punch milling machine processing ceramic fiber board.

- Q: What is the density of ceramic fiber modules? The best insulation effect

- Ceramic fiber module density is only a standard in the world, is 220Kg/m fand, but in the actual application, according to the heat treatment furnace, furnace temperature, combustion medium, temperature rise requirement of ceramic fiber module density in 200-240Kg/m fand, ceramic fiber blanket, because the processing of ceramic fiber module uses double roller today advanced technology and technology of silk, fiber length of the ceramic fiber blanket which produced in 80-130 mm, so the maximum density of the ceramic fiber module is more than the density, 240Kg/m fand, a large amount of fiber fracture, the fracture rate is as high as 48%. So after the actual verification at home and abroad of tens of thousands of industrial furnaces, the best density of ceramic fiber module is fand 220Kg/m.

- Q: Should the ceramic fiber furnace be compacted?

- The simplest, the least durable method, uses ceramic fiber blankets for wrapping, which is often caused by the poor density of the ceramic fiber blanket and the lack of anchorage

- Q: What is the difference between the ceramic fiber cloth and the high silicon oxygen cloth?

- 1. Ceramic fibers are short fibers that need to be strengthened and toughened by other objects. They are generally toughened by glass fiber and stainless steel wire.2 and high silicon oxygen is long fiber, no need to toughen by other objects.3 short, high silicon oxygen resistance to high temperature, Suzhou Dexin ceramic high silica cloth of silica content is greater than or equal to 96% temperature up to 1700 DEG C.

- Q: Glass fiber cotton, aluminum silicate cotton, rock wool, what's the difference between these three?

- Three kinds of materials are heat insulation materials, applications and temperature resistance is different.Glass fiber cotton is a kind of excellent performance of inorganic non-metallic materials, variety, has the advantages of good insulation, strong heat resistance, good corrosion resistance, high mechanical strength, but the disadvantage is brittle, poor wear resistance, the maximum temperature of four less than Baidu.

- Q: Is the ceramic fiber cloth poisonous?

- With aluminum, zinc and other non-ferrous molten metal erosion capacity. Excellent high temperature strength. The bottom heat conductivity makes the product have good heat insulation performance. Excellent electrical insulation performance. Non-toxic, harmless, no adverse effects on the environment, excellent tensile properties.

- Q: What is the diameter of the ceramic fiber? How to mix?

- Fiber length: fiber rejection is longer, the rejection of silk fiber is generally 150-250mm, spinneret fiber is generally 100-200mm;

- Q: The difference between the ceramic fiber blanket and rock cotton blanket

- The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.

- Q: Aluminum silicate needle carpet and ceramic fiber insulation performance of the good

- Aluminosilicate ceramic fiber has two different production processes, respectively, the rejection process and the blowing process. The carpet produced by the spinning process has long fiber length, high tensile strength and wide range of use. The blanket produced by blowing process is short in length and easy to break, and the scope of application is relatively narrow.

- Q: Ceramic fiber material fire shutter door how many square?

- Now there are two kinds of rolling to use ceramic fiber: a called inorganic super fire shutter (commonly known as the double track curtain), the curtain surface is glass fiber cloth + ceramic fiber cloth + ceramic fiber blanket + aluminum foil cloth, one is WFJ (glass fiber cloth + ceramic fiber cloth + glass fiber cloth).

Send your message to us

High Temperature Density Ceramic Fiber Bulk

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords