High Quality Plastic Threaded Pipe Fittings for New PPR Household Plastic Pipe Suppliers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

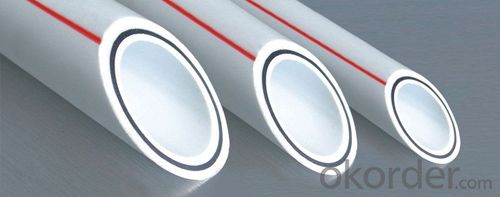

Introduction:

1.It is used in industrial fields, agriculture and garden irrigation

2. Beauty appearance.

3.Thermal insulation and energy saving.

4. Easy installation

5.excellent heat resistance and pressure resistance

6. affordable price

Quick Details:

| 1.Material: | PPR |

| 2Color: | White,Gray,Green,or as your required |

| 3.Size: | 20-110mm |

| 4.Logo: | CMAX or Customized |

| 5.MOQ: | 500pcs |

| 6.OEM Accepted: | Yes |

| 7.Certification available: | Yes |

| 8.Packing Details: | Weaving Bag |

| 9.Production Capacity: | 5,000,000pcs Per month |

Specifications:

1) Material:HYOSUNG R200P, Basell H5416

2) Size:20-160MM

3) Standard:DIN8077/8078

4) Pressure:PN10

PPR Pipes Advantages:

1. Sanitization & Non-poison: This product is green building material which is able to use for pure clean drinking water pipe system. No heavy metal additives would not be covered with dirt or contaminated by bacterium.

2. High Temperature Resistance: the maximum sustained working temperature is up to 70 Degrees Celsius, the maximum transient temperature is up to 95 Degrees Celsius.

3. Corrosion-Proof & Non-Fouling: Resist chemical matters or electron chemical corrosion. Able to avoid the pipe's fouling or blocking as well as the blemish, rust on basin and bath.

4. Heat Preservation & Energy-Saving: Excellent heat insulation features, minimal thermal conductivity which is only 0.5% of the conductivity of metal pipes.

5. Less Weight & High Strength: Its proportion is only 1/8th of metal pipe’s, with pressure-proof strength up to over 5MPa(50kg/sqcm),high tenacity and impact resistance.

FAQ

Q1. Can I have a sample order for valve?

A: Yes, we welcome sample order to test and check quality.Mixed samples are acceptable.

Q2. Do you have any MOQ limit for valve order?

A: Low MOQ, 1pc for sample checking is available

Q3. How do you ship the goods and how long does it take to arrive?

A: We usually ship by sea. It usually takes 30 days to arrive. Airline shipping also optional.

Q4. How to proceed an order for valve?

A: Firstly let us know your requirements or application. Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

- Q: Are plastic pipe fittings resistant to ozone?

- Yes, plastic pipe fittings are generally resistant to ozone.

- Q: Can plastic pipe fittings be used for geosynthetic clay liner systems?

- No, plastic pipe fittings cannot be used for geosynthetic clay liner systems. Geosynthetic clay liners require specialized fittings designed specifically for their installation to ensure proper functionality and performance.

- Q: Are plastic pipe fittings prone to leaks?

- Plastic pipe fittings are generally less prone to leaks compared to other materials such as metal or rubber fittings. However, just like any other fittings, the risk of leaks can still exist if they are not installed properly or used beyond their recommended limits. Regular inspection and maintenance are crucial to ensure a leak-free plumbing system.

- Q: Are plastic pipe fittings suitable for both residential and industrial applications?

- Yes, plastic pipe fittings are suitable for both residential and industrial applications. They offer various advantages such as durability, corrosion resistance, and ease of installation, making them suitable for a wide range of plumbing needs in both residential and industrial settings.

- Q: What types of plastic are commonly used for pipe fittings?

- Commonly used types of plastic for pipe fittings include PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride), and PEX (cross-linked polyethylene).

- Q: Are plastic pipe fittings prone to clogging?

- Plastic pipe fittings are generally not prone to clogging, as they have smooth interiors that allow for the smooth flow of water or other fluids. However, clogging can occur if foreign objects or debris enter the pipe system or if the fittings are improperly installed or damaged. Regular maintenance and proper installation can help prevent clogging issues in plastic pipe fittings.

- Q: Can plastic pipe fittings be used in wastewater treatment systems?

- Yes, plastic pipe fittings can be used in wastewater treatment systems. Plastic fittings are commonly used in these systems due to their corrosion resistance, durability, and cost-effectiveness. They are suitable for various applications, including the transport and distribution of wastewater, as they can withstand the harsh conditions and chemicals present in these systems.

- Q: Can plastic pipe fittings be used in areas with high water pressure?

- Yes, plastic pipe fittings can be used in areas with high water pressure. However, it is crucial to ensure that the plastic fittings are specifically designed and rated for high-pressure applications. Using fittings that are not suitable for high water pressure can result in leaks, bursts, and other plumbing issues. It is advisable to consult with a professional plumber or refer to the manufacturer's guidelines to determine the suitability of plastic pipe fittings for a particular high-pressure area.

- Q: Can plastic pipe fittings be used in culvert systems?

- Yes, plastic pipe fittings can be used in culvert systems. Plastic pipe fittings are commonly used in culvert systems due to their durability, corrosion resistance, and ease of installation. They are lightweight, cost-effective, and can withstand the pressures and environmental conditions typically found in culvert systems. Additionally, plastic pipe fittings offer a variety of options to accommodate different pipe sizes and configurations, making them suitable for various culvert applications.

- Q: Are plastic pipe fittings resistant to electromagnetic interference?

- No, plastic pipe fittings are not generally resistant to electromagnetic interference.

Send your message to us

High Quality Plastic Threaded Pipe Fittings for New PPR Household Plastic Pipe Suppliers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords