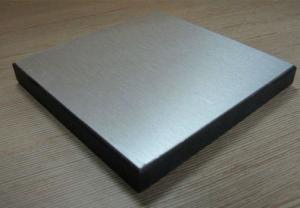

High Quality Laminated Wood Shelf Board - Raw & Melamine Chipboard for Furniture

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 21 Cubic Meter/Cubic Meters 1x20ft container m³

- Supply Capability:

- 150000 Piece/Pieces per Month m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of High Quality Raw Chipboard & Melamine Chipboard for Furniture

| Size | 1220*2440mm ,1830x2440mm,1830*3660mm |

| Thickness | 2.5-30mm |

| Gule | MR/ E1/E2/Melamine/WBP |

| Face/Back | Sanding or unsanding |

| Plain /veneer/melamine paper | |

| Usage | Kitchen,furniture,cabinet |

| Material | Poplar/combi |

| Moisture | Less than 8% |

| Density | 660-730kg/m3 |

| Certificate | ISO9001, ISO14001, CARB,CE |

| Main market | America, Canada, European, Middle-east, India.etc |

Features of High Quality Raw Chipboard & Melamine Chipboard for Furniture

1) High bending strength

2) little linear expansion con-efficient

3) Strong nail holding

4) Moisture proof and easy work

5) Tight construction and high strength

6) No ratten or decay

7) Low formaldehyde emission

Certificate---ISO 9001:2000, CE, CARB

Packing:

---Inter packing:0.20mm plastic bag

---Outer packing:pallets are covered with plywood/ carton and then steel tapes for strengh, or as requested

Quantity:

20'GP --- 8pallets / 21 m³

40'GP ---16pallets / 42 m³

40'HQ ---18pallets / 53 m³

Applications of Chipboard---furniture, construction, decoration, packing

Delivery-Within 15-30 days after receiving deposit.

Packing & Loading Pics

- Q: What is the main role of the core board

- while the buffer due to the uneven growth of the core board to the flatness of the board to bring the adverse effects, The top of the dough (thin veneer, generally not more than 1MM)

- Q: Blockboard surface rough, how to process

- due to the rough surface of the blockboard, so the carpentry field processing, the surface treatment is usually used when a large number of the use of glue or paint,

- Q: Tectonic characteristics of blockboard

- Since the blockboard is a special plywood, it is also necessary to follow the principle of symmetry in the production process to avoid warpage of the plate.

- Q: he blockboard spreads the wood odor to identify

- The width of the core can not exceed 2.5 times the thickness, or easy to deformation; core should be no decay, fracture, wormhole, knots and so on.

- Q: Some of the ecological board of the core board, is the blockboard to do

- In short, a word, no-paint board and the main difference between the main use to see where

- Q: How to identify the blockboard

- National wood-based panel quality supervision and inspection center director Lu Bin remind consumers: environmental protection, quality, service, is the choice of consumers when the plate

- Q: What are the characteristics of blockboards

- And the inner layer of single board known as the core plate or plate, with the worst quality single plate composition.

- Q: What is the difference between eco-board and blockboard?

- which has a serious impact on the human body, and the high cost of materials, labor costs have, there are a lot of time to pay, so it seems, free Paint board is more advantageous.

- Q: Blockboard generally have any specifications?

- ??Blockboard commonly known as large core board, is made of two pieces of plastic plate from the middle of the pressure from the wood.

- Q: Specification of the fine board:

- Commonly used blockboard thickness of 17mm, there are: 12mm, 15mm, 17mm, 20mm four, 15mm and 17mm is the more commonly used thickness, different thickness will lead to different prices

Send your message to us

High Quality Laminated Wood Shelf Board - Raw & Melamine Chipboard for Furniture

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 21 Cubic Meter/Cubic Meters 1x20ft container m³

- Supply Capability:

- 150000 Piece/Pieces per Month m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords