High-Quality Magnesite Brick - Fused Magnesia Refractory Bricks

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

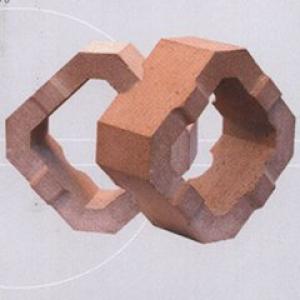

Magnesia checker brick for glass furnace

Product Description

Application:

As an excellent material ,can be used for magnesia bricks, unshaped refractory materials.

At same time can be used in metallurgy, building materials, chemical industry, national defense, scientific research, aerospace, medical equipment components and household appliances

products technical:

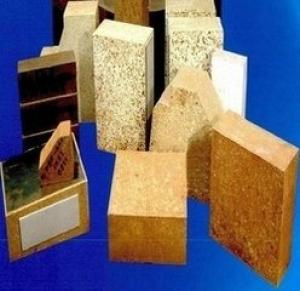

1.The products are fused magnesia as main raw material, after a reasonable size distribution, high pressure forming, high-temperature sintering. The product has strong resistance to slag corrosion ability and high temperature dimensional stability. Mainly used in glass furnace regenerator, the upper part.

2.The regular magnesia bricks are made from dense dead burned magnesia that makes the bricks in good refractoriness, corrosion-resistance, and widely used in checker chamber of glass tank, lime kiln, non-ferrous metallurgical furnaces, open heart furnace, iron mixer and EAF of steel-making, and also ferro-alloy furnace, etc.

The bricks with MgO 95% or more in content take the secondary-burning dead burned magnesia or electrofused magnesia as the raw material and bured under the condition of ultra high temperature. They have the features of highly directly bonded and corrosion-resistance and widely used in various kinds of high temperature kilns and furnaces

Magnesia Brick Features:

Excellent performance of basic slag resistance, high refractoriness, thermal stability, anti-erosion and anti-peeling

Excellent strength of pressure bending, abrasion proof

Excellent performance of high-temperature firing, high rates of associative property, anti-erosion ability

Excellent thermal shock resistance and spalling resistance

Excellent ability of high refractoriness, anti-erosion of alkaline residue;

High temperature load of refractoriness under load. High mechanical strength

High temperature resistance Excellent corrosion resistance

Resistance to spalling

Technical Index

Behaviors | |||||

Item | Fused Rebonding Magnesia Brick | ||||

DMZ-95 | DMZ-96 | DMZ-97 | DMZ-98 | ||

Chemical | MgO % | ≥95 | ≥96 | ≥97 | ≥97.5 |

composition | SiO2 % | ≤1.5 | ≤1.2 | ≤1.0 | ≤0.5 |

CaO % | ≤1.5 | ≤1.2 | ≤1.2 | ≤0.6 | |

Apparent Porosity % | ≤18 | ≤18 | ≤17 | ≤15 | |

Cold Crushing Strength Mpa | ≥55 | ≥60 | ≥60 | ≥60 | |

0.2Mpa Refractoriness Under Load T0.6 | ≥1650 | ≥1680 | ≥1700 | ≥1700 | |

Bulk Density g/cm3 | ≥2.95 | ≥3.0 | ≥3.05 | ≥3.05 | |

Thermal Stability 950°C Wind cycles | ≥15 | ≥20 | ≥20 | ≥20 | |

other products

- Q: What is the ratio of magnesia refractory bricks to brine? For example, what is the difference between the 97 and 95 with 92 brick brick brick material mixed with brine ratio?

- In addition to the brine binder burned magnesia brick and sulfite pulp waste liquid, Magnesium Sulfate solution binder is generally around 3%

- Q: The index of magnesia brick

- Room temperature compressive strength≥(MPa)(15-25-)24.5-24.5-24.5-24.5-40-40-40

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- The super high alumina brick in high alumina refractory brick has the highest refractoriness, and the corresponding production cost is higher.

- Q: With different capacitance magnesia brick brick

- Burnt magnesia brick is made of high quality sintered magnesia as main raw materials, paper pulp as binder. After mixing and high pressure molding, it is fired in a high temperature tunnel kiln over 1550 degrees celsius.

- Q: Magnesia brick

- Magnesia brick (magnesite brick) basic refractories Magnesium Oxide content of more than 90%, with the main crystalline phase of periclase. General can be divided into sintered magnesia brick (also called burnt magnesia brick) and chemically bonded magnesia brick (also known as the two major categories of not burned magnesia brick). Purity and high firing temperature of magnesia, due to the direct contact of periclase grains, known as direct bonded magnesite brick; made of fused magnesia bricks called electrically fused magnesite brick.

- Q: How to identify the fused magnesia brick and sintered magnesia brick

- Magnesia brick have high refractoriness, alkali slag good performance, high load softening temperature, but poor thermal shock resistance. The sintering magnesia brick brick magnesite as raw material, crushing, proportioning, mixing, forming, in 1550 ~ 1600 degrees firing, high purity products firing temperature is over 1750 DEG C. Don't add chemical bond magnesia brick is appropriate in magnesia, through mixing, molding and drying.

- Q: Process for producing magnesia chrome brick

- The oxide of iron reacts to produce a loose effect caused by the expansion of the spinel. Also, the magnesia chrome brick can be made from the synthetic common sintered material. In addition, there are non burned magnesia chrome bricks, for example, non burned magnesia chrome bricks combined with inorganic magnesium salt solutions. The unfired magnesia chrome brick has the advantages of simple production process, low cost and good thermal stability, but the strength of the high temperature is far less than that of the burnt brick. In the late 50s, a so-called "direct bonding" magnesia chrome brick was developed. The characteristics of this brick raw material is pure, high firing temperature, periclase and spinel phase with high temperature directly, silicate and other low melting point phase for island distribution, therefore, significantly improve the high temperature strength and slag resistance of brick.

- Q: How do you differentiate between the two clearly? Where is the key? Thank you

- Magnesia brick (magnesite brick) basic refractories Magnesium Oxide content of more than 90%, with the main crystalline phase of periclaseGeneral can be divided into sintered magnesia brick (also called burnt magnesia brick) and chemically bonded magnesia brick (also known as the two major categories of not burned magnesia brick). Purity and high firing temperature of magnesia, due to the direct contact of periclase grains, known as direct bonded magnesite brick; made of fused magnesia bricks called electrically fused magnesite brick.

- Q: Magnesite chrome brick, magnesia chrome brick indicators? What is the price?.

- If you want to know the indicators of chrome brick, magnesia chrome brick must know you are in what furnace above, there is in what position

- Q: Combined with the ordinary clay brick and magnesia brick as an example, the existence of impurities in minerals and refractories production main components of the formed liquid relative what affect the performance.

- The main varieties of common magnesia brick, magnesia brick, magnesia brick, magnesia brick high pure grade. Product main mineral phase is periclase, volume has high stability and anti erosion ability. Literature is widely used in steelmaking, non-ferrous metal smelting and other high-temperature industrial furnace.

Send your message to us

High-Quality Magnesite Brick - Fused Magnesia Refractory Bricks

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords