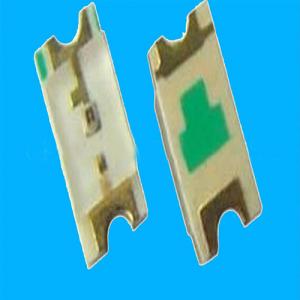

High Quality LED SMD 1204 Royal Blue Color 470Nm High Brightness

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Introduction

LED SMD 1204 Royal Blue Color 470Nm High Brightness

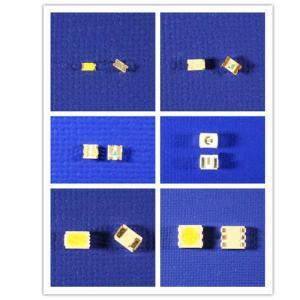

Specification

Part Number | Emitted Color | WD(nm)/ CCT | Lens Color | Vf(V) IF=@20mA | Iv(mcd) IF=@20mA | Viewing Angle | ||

Typ | Max | Min | Typ | |||||

S1204SDRC/50-19 | Deep Red | 640 |

Water Clear | 1.8 | 2.4 | 20 | 40 | 120 |

S1204SRC/50-19 | Red | 625 | 1.8 | 2.4 | 60 | 120 | 120 | |

S1204SOC/50-19 | Orange | 610 | 1.8 | 2.4 | 60 | 120 | 120 | |

S1204SYGC/50-19 | Yellow Green | 570 | 1.8 | 2.4 | 30 | 50 | 120 | |

S1204SYC/50-19 | Yellow | 589 | 1.8 | 2.4 | 60 | 120 | 120 | |

S1204SUGC/50-19 | Green | 525 | 2.8 | 3.6 | 300 | 600 | 120 | |

S1204UBC/50-19 | Blue | 470 | 2.8 | 3.6 | 60 | 120 | 120 | |

Features

Extremely wide viewing angle

Suitable for all SMT assembly and solder process

RoHs compliant

Package:3,000pcs/reel

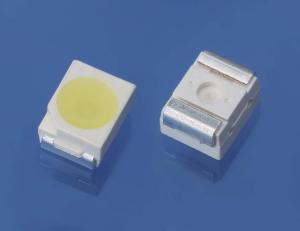

Applications

Indoor and out door commercial light

LED backlighting and SMD type indicator

LED midule and LED strip light

Decoration light

Auto lamp

Other More

Color: Red, Blue, Green, Yellow, White etc.

We also have driver, heat sink and lens for sale.

The more you buy, the cheaper it is!

- Q: Production of a number of substrates, the use of SMD LED lights, red lights and green lights are not bad, blue lights appear mass dark, do not know why? Is the LED blue light material easy to use dark?

- The pressure drop of the blue light is greater than that of the red light and the green light. If the series connection is the same as that of the green light and red light, the current limiting resistor will tend to dim

- Q: What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- Epoxy resins turn yellow during short wave irradiation or long periods of high temperature, so they are very short lived when applied to high power lighting. That's why the LED lighting market is dominated by silica gel.But because of the low price of epoxy resin (silica gel and not at a level), and storage, use and processing is superior to silica gel, so the low power LED and some optical components still use epoxy resin package.

- Q: LED patch lamp band, how to calculate how many watts a meter, such as 3528-60 beads is how much?

- 3528-60 is 60 meters per lamp, 3528 SMD lamp with no 5050 light, about 10 watts per meter. Copper wires have less resistance and may be less than 10 watts per meter.

- Q: How does the LED placement lamp distinguish the positive and negative poles? There is no sign on the light. Thank you

- You can also use the ohmmeter's ohmmeter. To dial multimeter, to "ohm X1" file, the light emitting diode when the red pen is connected to the positive terminal of SMD LED, the black probe is connected to the negative terminal of SMD LED.

- Q: What, in what way do I shunt the LED?

- LED lights are current driven, first of all, look at your LED's IF and VF values. How much power do you have?. Make sure the current is in line with the IF and the current limit can be achieved with resistors.

- Q: What is the difference between patch LED beads and LED beads: General

- A pin of the lamp, and outside a resin cap, because the reason LED beads can spotlight cap;There is no pin on the patch and there is no resin cap outside. Because of the lack of cap, the LED patch can not be concentrated.Patch is based on small power, the shape is relatively small (usually 0.5 and 0.5W products)It's called patch because some small ones need Mounter to machine.The ordinary LED lamp, solder joints than SMD beads, now is the largest artificial welding. Regular watts count from 1-300W

- Q: What are the storage requirements of SMT patch LED (LED)?

- Clean? use no designated chemical liquids to clean SMD LED. These chemicals may damage SMD LED.. When necessary, wipe LED at room temperature with alcohol and dry at room temperature for 15 minutes before use? the effect of ultrasonic cleaning on SMD LED is related to the ultrasonic power and the SMD LED assembly method, and shall be checked in advance to ensure that the ultrasonic cleaning process does not impair the SMD LED

- Q: What is patch LED?

- Patch LED refers to surface mount LED.The LED is separated from the PCB board in the form of inline and surface mount. Piranha, 3mm lights, and 5mm lights are all pins. While most high-power LED is surface mount, that is, patches. Small power LED also has the form of surface mount such as PLCC-2 and PLCC-4.

- Q: Notes on patch LED

- Clean, do not use an unknown chemical liquid to clean the patch LED: an unknown chemical liquid may damage the patch LED. When necessary, immerse the patch LED in alcohol, less than 1 minutes at normal room temperature, and dry naturally for 15 minutes before starting to use

- Q: Such as title, please have welding patch LED lamp experience expert guidance, do not search from the Internet to the theoretical knowledge, thank you!

- If the power of the lamp, because heat high power do very well, so not good welding, the temperature at the highest (300 degrees), the use of horseshoe iron head, not waiting to solder, because the heat is very powerful, quick action.

Send your message to us

High Quality LED SMD 1204 Royal Blue Color 470Nm High Brightness

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches