High quality for Tricycle carriage board production equipment Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

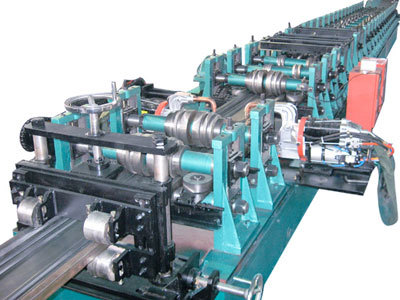

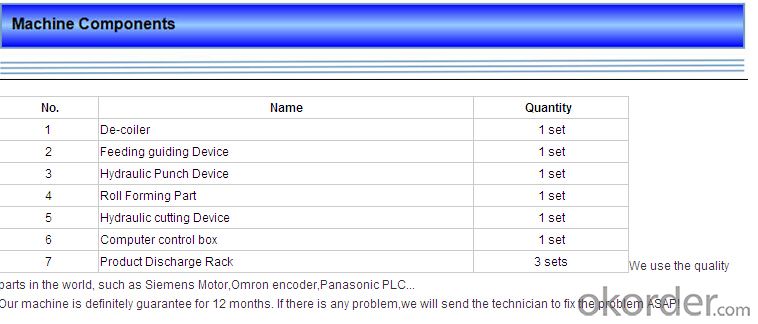

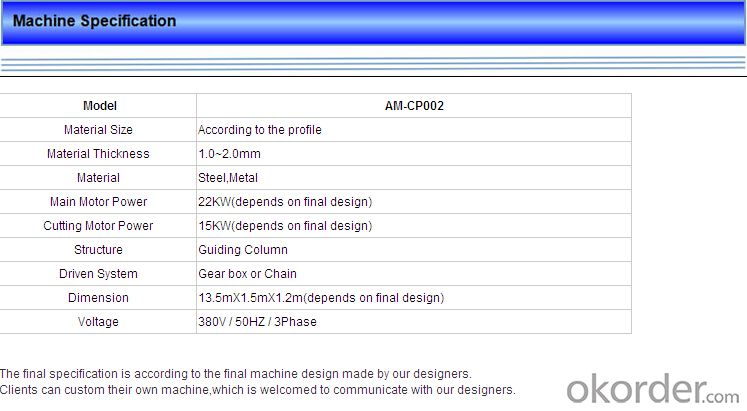

1,carriage board forming equipment

2,Full automatic

3,Customized design

4,Finland technology

5,CE

carriage board forming equipment

All the informations here including the specifications and the product pictures are based on the machine that we've export lately.

Please have a look for the reference.

| No. | Machine Name |

| 1 | Roll forming machine |

| 2 | Roll forming line |

| 3 | Roll former |

| 4 | Roll former line |

| 5 | Rolling machine |

| 6 | Rolling line |

| 7 | Cold roll forming machine |

| 8 | Cold roll forming line |

If you are tired of those Chinese bad machines, and want to buy high quality machines in China, Just stop searching!we are your best choice!We offer you quality machine with good price!

Our main products include roll forming machines, guardrail roll forming machines, steel deck forming machines, door & window frame roll forming equipment, steel metal door making lines, guide rail rollforming machines, upright post roll formers, pipe and tube roll formers, purlin cold roll forming machines, T-bar forming machines, grape trellis roll forming machines, roof tile forming machines, steel metal panel roll forming machines, stud and track forming machines, cable tray roll forming machines, shelf rack making machines, gutter roll forming machines, roller shutter manufacturing lines, car bumper forming machines, car door forming machines, distribution cabinet making machines, channel roll forming machines and so on.

- Q: A roll forming machine, rolling out of the length is always not up to a fixed size, not too small, that is, more than that, what is the cause?

- According to my experience, there should be a problem with the boot encoder (also known as the digital wheel). Thank you. I hope I can help you.

- Q: What is rolling forming processing?

- Rolling process is a kind of pressure finishing, which is a kind of cold plastic characteristic of metal under normal condition.

- Q: Improvement in rolling forming process

- The utility model has the advantages of short service life, easy damage and high comprehensive use cost.

- Q: Introduction of roll forming process

- Roll forming began around 1960s in europe. Because of roll forming, the working model has the advantages of high production efficiency, saving material and increasing product strength.

- Q: What kind of material and what heat treatment are used for pressing roller (molding, feeding, cutting force, heavy load, heavy load) of sheet steel rolling machine?

- Generally speaking, to consider the use of rollers in the requirements, including: 1., good wear resistance, 2. toughness, 3., high hardness, 4. hardened layer (easy to wear after repeated repair)

- Q: What is the surface rolling forming machine process?

- The rolling process using metal at room temperature, cold plastic characteristic, through the rolling tool is the rolling tool to put some pressure on the metal surface, so that the workpiece surface by plastic deformation, the height to the lower tissue slip, the surface roughness decreased.

- Q: Process mould for rolling forming process

- Press forming is an advanced processing technology, and its remarkable characteristics have been paid attention to by the automobile industry at home and abroad.

- Q: Material and equipment for roll forming process

- The most common type of roll forming is reciprocating flat wire twisting machine. Therefore, for the manufacturers of cold heading machines and screw rolling mills, the design of rolling dies is only a matter of design.

Send your message to us

High quality for Tricycle carriage board production equipment Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches