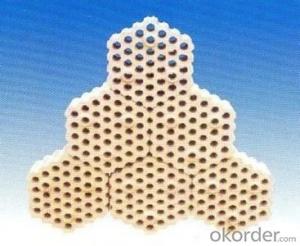

High-Quality Corundum Brick Castable Corundum CNBM Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

white corundum/alundum F46#:

1.High purity of 99%min

2.Manufacturer,not trading company

3.Experience-15years

Description:

white corundum/alundum abrasives, a kind of high-grade refractories, was made from the high quality alumina by melting above 2000 in the electric arc furnace and cooling. It is white with the main crystal phase

alpha-Al2O3. The white alumina produced in titling electric arc furnace has the advantage of high bulk density and low porosity and the volume stability and thermal shock resistance can be improved.

The chemical and physical analysis for white corumdum/alundum:

Chemical Analysis | Typical | Specification |

Al2O3 | 99.55 % | 99.50(min) |

SiO2 | 0.04 % | - |

Fe2O3 | 0.04 % | - |

CaO | 0.03 % | - |

MgO | 0.02 % | - |

Na2O | 0.22 % | - |

K2O | 0.01 % | - |

Physical properties | Tipycal | Specification |

Bulk density | 1.53-1.99g/cm3 | 1.75-1.95g/cm3 |

Bulk Density | 3.95g/cm3 | 3.90g/cm3 |

Morse hardness | 9 |

|

Micro hardness | 21600-22600kg/mm3 |

|

Mineralogy | Predominantly Alpha Alumina | |

- Q: How much is a thermal brick?

- Insulation brick prices also have a great relationship with the material and workmanship, such as clay brick price is much lower than high alumina brick, mullite and corundum brick prices will be higher.

- Q: How much is a refractory brick?

- This question is too general, refractory bricks according to the use of the environment and industry, there are a variety of materials, a variety of specifications, prices vary greatly.

- Q: What is the blast furnace ceramic cup called by the refractory factory?

- In fact, a kind of ceramic cup of blast furnace refractories, application in blast furnace bottom and hearth contact steel lining using a layer of non carbon refractory materials, such as Theron with corundum brick, corundum mullite and synthetic mullite bricks etc..

- Q: What equipment is used for producing diamond blanks? How much is the investment?

- You'll have to invest about about one million if you want an electric furnace. A power distribution room is easiest to approach one hundred thousand. Electric furnaces, power distribution cabinets and transformers must be around one hundred and ten thousand.

- Q: Which is good, glazed brick and whole cast glazed brick?

- These two tiles have their respective advantages and disadvantages, in fact, to say which kind of good, mainly depends on the decoration of personal preferences and the location of the shop. If it is only the shop wall, then design and pattern rich whole glazed tile is good, it can make the room impressive, improve decorative effect, make the decoration style to fit the characteristics of his personality. In addition, clean up is relatively easy, not easy to contaminated with oil stains and other pollutants. If you are laying tile, suggested the use of tiles, tiles of good antiskid effect, water absorption rate is relatively low, so the kitchen toilet bathroom and other wet places is not easy to water seepage, improve the convenience of life.

- Q: What is the hardness of corundum refractory bricks?

- Corundum refractory brick has good stability against acid and alkaline slag, metal and glass solution. It can be used in oxidizing atmosphere at high temperature or in a reductive atmosphere. The basic material of corundum refractory brick is fused alumina or sintered corundum.

- Q: What is the difference between corundum and high alumina?

- The main components of high alumina brick are high alumina bauxite, mullite and partial corundum sand.The difference between them lies in the content of alumina and the alumina refractory products with alumina content higher than 48%The content of Al2O3 is higher than 90%, which is called corundum brick.

- Q: High temperature refractory material?

- Acid refractory with silicon oxide (SiO2) as the main ingredient, commonly used are silica brick and clay brick is siliceous. Products containing more than 93% SiO2, the use of raw materials with silica, silica and other waste brick. Acid slag erosion ability is strong, but vulnerable to the erosion of basic slag, its softening temperature is very high that is close to the refractory, the volume does not shrink after repeated burning, or even a slight swelling, but the thermal shock stability. Silica is mainly used for thermal equipment of coke oven, glass furnace, furnace and other acidic silica brick, according to the physicochemical indexes and SiO2 content can be divided into several levels, mainly brick for glass furnaces and used for coke oven two kinds of brick clay brick. With refractory clay or bauxite clinker as main raw material, containing 30% to 46% of alumina, refractory degrees 1580 to 1770 DEG C, weak acid refractory material, heat shock resistance, resistance to acid slag, wide application Pan, clay brick with refractory clay as main raw material is called ordinary clay brick, made with bauxite clinker as main raw material, the porosity in the clay brick below 17% is called low porosity clay brick. Two kinds of clay brick and according to the physicochemical indexes which were divided into several grades, the price difference between ordinary clay brick and low porosity clay brick greatly.

- Q: What's the size of the fused zirconia corundum refractories for glass furnace? What are the main kilns? How much is the dosage?

- Fused zirconia corundum refractory material of glass fiber kiln quantity is little, generally used in the kiln feed arch furnace flue, where large amount of places are currently using dense zirconium Zr, dense chromium

- Q: What are the refractory materials?

- Acid refractory with silicon oxide as the main component, are commonly used in brick and clay brick. Silica is silica containing more than 93% silica products, raw materials used in silica, silica and other waste, the acid resistance of slag erosion ability, high load softening temperature, volume shrinkage after repeated burning, or even a slight expansion; but it is vulnerable to the erosion of basic slag, low thermal shock resistance. The brick is mainly used for thermal equipment of glass furnace, coke oven, acid furnace etc.. Clay brick with refractory clay as the main raw material, containing 30% to 46% of alumina, weak acid refractory material, heat shock resistance, resistance to acid slag, widely used.

Send your message to us

High-Quality Corundum Brick Castable Corundum CNBM Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches