High quality alcohol stainless fermentation tank

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Fermentation tank

Our factory supplies manufacturing various stainless steel tanks with orwithout jacket, agitation etc.

1.Specifications

1)Materials: SUS304, SUS316.

2) Design Tem: asper design

3)Design P: as perdesign

4)Capacity:as per design

5)Manufacture standard: ASME GB/T

6)Design service:provided

7)After-salesservice: provided

8)Service life:fifteen years

2. Our products contain 5 assortments :

1)chemicalsassortments(ethanol,methanol,furfuraldehyde,etc.)

2) food assortments,

3) dairy assortments,

4) pharmaceutical assortments,

5) beverage assortments.

3. Here is the main products of stainless steel tanks:

1) Water tank,

2)storage tank,

3)prcoess tank,

4)beer tank,

5)dairy tank,

6)reactor tank,

7)fermenting tank,

8)vacuum tank,

9)any style of tank made of stainless steel ,platform,worktable,goodsshelf,wheel car,tank car,whatever made of stainless steel products.

If you have any interested in our products please contact me feel free.

2.New Technology Description:

Five-Column Three-Effect Distillation Process

Our company designs and manufactures latestFive-Column Three-Effect Distillation equipment.This new process is promoted on the basis of traditional five-column differential-pressure column and mainly used for super-fine alcohol production.

The key of this process is the heating methods,the steam heats one column directly and transfers theheat to other 4 columnsto achieve three-effect thermal coupling and energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing of circulating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table Of Five-Column

Three-Effect Distillation Process for Super-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

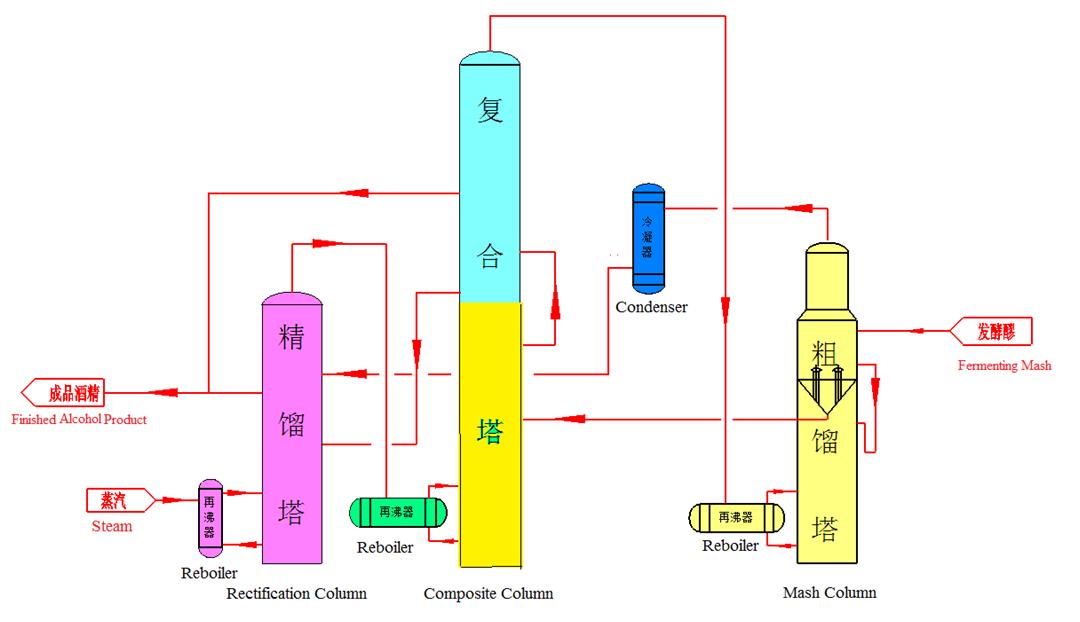

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production of general-grade alcohol& fuel ethanol, and it was awarded Chinese national patent, it is the onlysuccessfulapplicationof double mash column & three-effect in the world,which produces general-grade alcohol.

This process is composed by mash column, rectification column and composite column. The composite column functions as mash column and rectification column.

The key of this process is the heating methods: the steam heats one column directly and transfers the heat to other 2 columns to achieve three-effect thermal coupling and energy-saving effects.

The advantage of this process is energy-saving;it saves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s, designed and manufactured the first stainless steel distillation column in China.

2. Our company can produce 6 full sets of equipment (including crushing section, liquefying saccharification section, fermentation section, distillation section and DDGS section) in a month.

3. Among 16 production workshops,3 workshops are for mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshops are for assembling & welding.

4. We own advanced machining equipment and product testing equipment.

4. Designed capability

1). We own Design License of Special Equipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class; Design License of Special Equipment GC Class.

2).Our company achieves more than 20 patent certificates on distillation, DDGS, and other fields.

3). Our company owns ASME certification, ISO 9001 Quality System Certification, ISO 14001 Environmental Management System Certification & GB/T28001 Occupational Health and Safety Management System Certification

1).Our company can provide a sophisticated product after-sale service and can ensure the implementation, maintenance and commission of projects.

2). We can reach the project site after receiving the user’s notification.

6.Package & Transport

Our company can package the products according to enterprise export standard, and use container or bulk transport.

- Q: I'm going to make a liquid chlorine carburetor. The technical characteristics table is as follows: the tube working pressure MPa under the project.

- Pressure vessel is belong to GB150 tube, but should the rules don't return to dish tube, if the coil diameter dn < 150 mm, even if the product is greater than 2.5 MPa - P * V L, is zoned category is not only the inspection, but the coil diameter dn > 150 mm, nine times out of ten classes and inspection.

- Q: What is a hot sleeve pressure vessel

- A layer of packing is covered by a layer of thin sheet and welded. The cylinder, the cylinder, and the cylinder of the inner tube and the inner tube. Sheet can be used instead of single precious metal or composite steel pressure vessel, reduce the cost and improve the safety performance of the dual role, is applicable to from low to medium temperature, atmospheric pressure to high pressure, all kinds of working medium and diameter is not too great in the occasion of special requirements The inner lining pressure vessel is usually lined with stainless steel or non-ferrous metal plates, mainly to prevent corrosion of the cylinder body.

- Q: Pressure vessel pressure gauge due how to test

- To the bureau of quality and technical supervision verification. To make money, or your company sent someone to textual research.

- Q: Company into a tube and shell heat exchanger, working pressure is 3 kilograms, can according to the provisions of the customs formalities for tax exemption, but customs has a regulation: high pressure vessel cannot do duty-free, now I can provide the customs requirements 3 kilograms of pressure for high pressure of national standard, which is the national standard, please?

- TSG R0004-2009 type pressure vessel safety technology and supervision code Annex A The design of the pressure vessel pressure (p) is divided into low pressure, medium pressure, high pressure and ultrahigh pressure of four classes: (1) low pressure: L code, 0.1 MPa acuities were p < 1.6 MPa (2) the intermediate pressure: M code, 1.6 MPa acuities were p < 10.0 MPa (3) high pressure: code H, 10.0 MPa acuities were p < 100.0 MPa (4) the ultrahigh pressure: code U, p p 100.0 MPa Note: (1 kg pressure equal to 0.1 MPa) checked our design can know is that level

- Q: Does the pressure transmitter and pressure switch on the pressure vessel belong to mandatory inspection equipment

- All the pressure parts will be mandatory.

- Q: The burner (not the boiler) is the pressure vessel

- The definition of pressure vessels must be the vessel pressure, furnace, is actually the incinerator, do not belong to the scope of the pressure vessel has failed to achieve the most basic conditions, so not pressure vessels.

- Q: Must the pressure vessel be tested for safety?

- Hello, yes, but simple pressure containers don't.

- Q: Is the heat exchanger a pressure vessel

- A pressure vessel is an airtight device that is a gas or liquid that carries a certain amount of pressure. Storage containers, reaction containers, heat exchange containers and separating containers are pressure vessels. Not all of the pressure vessel to accept technical supervision departments of supervision and inspection, only in the related safety technical supervision regulations within the scope of the pressure vessel, such as the fixed rules ", "pan rules" and so on, to accept the supervision and inspection by technical supervision departments, and divided the corresponding category.

- Q: What pressure vessel is used for?

- Some more things, or atmospheric pressure cannot be saved.

- Q: What are the general pressure vessel parameters, sometimes design pressure, working pressure, the maximum allowable stress, etc., which is what meaning

- Above two has deviation! First of all, the friend, the first floor after the maximum allowable working pressure sometimes can be higher than the design pressure, the other is basically a correct answer. Friend, on the second floor of the maximum allowable working pressure has unified change to maximum allowable working pressure! Of article 4 of the "design pressure does not allow below the relief valve opening pressure". But when the maximum allowable working pressure vessel nameplate marked allows the relief valve opening pressure higher than the design pressure, higher than the maximum allowable working pressure are not allowed! That is good! Careful contrast should be able to find the right definition. Go!

Send your message to us

High quality alcohol stainless fermentation tank

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords