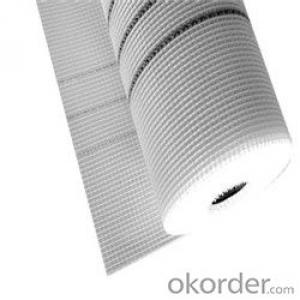

High Quality 135g 5x5 Fiberglass Mesh Cloth

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Concrete Fiberglass Mesh(Manufactory)

Weight:40~300g/m2.

Length: 30m,50m,90m, width:1m

Mesh:5*5MM 4*4M,8*8mm

stocks,as your instruction

Concrete Fiberglass Mesh(Manufactory)

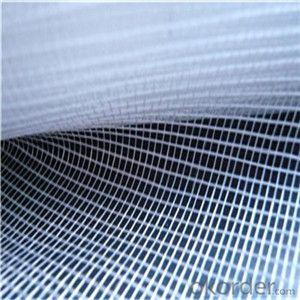

1. Wall reinforced material (such as fiberglass wall mesh, GRC wall panels, EPS insulation with the wall board, gypsum board, bitumen etc)

2. Reinforced cement products.

3. Used for Granite, mosaic, marble back mesh etc.

4.Waterproof membrane fabric, asphalt roofing.

5. Framework material for reinforced plastics, rubber products,.

6. Fire board.

7. Grinding wheel base fabric.

8. Road surface with geogrid

9. Construction caulking tape etc.

Main Specifications | Mesh size | Yarn density | Mass | |||

warp | weft | warp | weft | |||

1 | 4×4-75g/m2 | 4 | 4 | 48/2 | 200 | 75±3 |

2 | 4×4-90g/m2 | 4 | 4 | 67/2 | 200 | 90±3 |

3 | 4×4-145g/m2 | 4 | 4 | 134/2 | 240 | 145±5 |

4 | 4×4-160g/m2 | 4 | 4 | 134/2 | 300 | 160±5 |

5 | 4×5-110g/m2 | 4 | 5 | 100/2 | 360 | 110±5 |

6 | 4×5-125g/m2 | 4 | 5 | 100/2 | 280 | 125±5 |

7 | 4×5-145g/m2 | 4 | 5 | 134/2 | 300 | 145±5 |

8 | 4×5-160g/m2 | 4 | 5 | 134/2 | 360 | 160±5 |

9 | 5×5-90g/m2 | 5 | 5 | 67/2 | 240 | 90±3 |

10 | 5×5-125g/m2 | 5 | 5 | 100/2 | 340 | 125±5 |

11 | 5×5-145g/m2 | 5 | 5 | 134/2 | 360 | 145±5 |

12 | 5×5-160g/m2 | 5 | 5 | 134/2 | 430 | 160±5 |

13 | 10×10-90g/m2 | 10 | 10 | 200/2 | 300 | 90±3 |

14 | 10×10-110g/m2 | 10 | 10 | 250/2 | 450 | 110±5 |

、

- Q: How do you paste the mesh cloth on the back of the stone?

- Mesh cloth is used in home improvement projects for the grass-roots wall of the general name of anti cracking materials, mostly because of grid like name, also known as anti cracking cloth, anti cracking cloth mesh. The mesh cloth is usually made of glass fiber, and some people use cloth instead of anti cracking cloth in the actual construction. Wall cracking is a chronic disease of home improvement, so many people regard it as a magic weapon to prevent wall cracking. Different materials, new and old walls should be used.

- Q: What are the transverse and longitudinal tensile forces of alkali resistant glass fiber mesh cloth?

- The reason: the current domestic weaving factory method or pre roll beam weaving, and net fabric warp yarn and weft yarn is usually, roving, the intensity is greater than the warp weft. Secondly, to weave is usually weaving, woven to the continued strength of more than.

- Q: The difference between alkali resistant mesh fabric emulsion and urine glue 7.5

- Grid cloth stereotypes are used in the market, a wide range of species, can generally be divided into urine gel, latex twoThe grid cloth made of urine gum is hard, and the quality of latex is almost worse than that of latex

- Q: What kind of wall fabric is covered with fiberglass mesh? Do you apply the powder or the powder? Thank you

- The interior powder is usually used at the joint of the wall (there is a mesh fabric specially used for joint, called adhesive tape or joint tape)

- Q: The building is how to choose the external wall thermal insulation material of glass fiber mesh cloth?

- The building often causes the perineum to warm up and contract cold and cause cracks. Reduce the service life, glass fiber mesh cloth can be the maximum restraint to reduce such adverse effects. The glass fiber mesh cloth is insulated and used in the outer part of the main structure so as to save indoor space. It is effective enough for indoor use

- Q: Self-adhesive fiberglass mesh

- Self-adhesive mesh fabric is based on glass fiber mesh fabric as substrate, emulsion coating and self-adhesive coating. Therefore, it has good alkali resistance, softness and high tensile resistance at warp and weft direction. It can be widely used in EPS thermal insulation system.

- Q: Glass fiber mesh fabric stereotypes poor, general use of glue is acrylic emulsion, please add what accessories, you can finalize a better shape

- To increase the penetration of some surface active agent, increase the permeability of the emulsion, adding some phenolic thermosetting resin, melamine formaldehyde and improve sizing effect, to prevent the resurgence of soft, adding cationic film plasticized thermosetting resin while reducing fiber absorption and softening fiber

- Q: Self making method and formula of glass fiber mesh cloth shaping glue

- The inner wall heat preservation alkali resistant glass fiber net is made of alkali or alkali free glass fiber mesh cloth as base material, and then modified by coating acrylic ester copolymer liquid. It has the characteristics of light weight, high strength, temperature resistance, alkali resistance, waterproof, corrosion resistance, anti cracking and dimensional stability. It can effectively avoid the surface tension, shrinkage and cracking caused by external forces of the plastering layer, and the light mesh cloth is often used for wall renovation and internal wall insulation.

- Q: Can indoor glass fiber mesh cloth be stuck with wall tiles?

- Yes, glass fiber mesh is used for roofing, waterproofing and gypsum, marble, mosaic and other wall or plate reinforcement.

- Q: What is the use of alkali resistant fiberglass mesh cloth on the exterior wall?

- How to identify quality problems of alkali resistant glass fiber cloth, glass fiber cloth market price of 1. of the worst is usually around 1 yuan -1.60 yuan, his glass fiber is usually made of some kind of waste glass beer bottles, the production process for clay crucible drawing, production process is prohibited by the state, the surface coating is non alkali resistant emulsion. From the intuitive point of view: the work is relatively rough, generally sold in the market volume of the theory, often lack of length, grams of weight is not enough, two fold on the break, the contact is not firm, easy to shift, and easy to stab the skin. In the insulation layer in general in the two months after the loss of strength using the grid cloth, if the mortar off grid cloth out, just gently crushed, fiberglass yarn is made into powder.

Send your message to us

High Quality 135g 5x5 Fiberglass Mesh Cloth

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords