High Purity Alumina Ceramic Fiber Paper

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Fiber Paper

l Okorder ceramic fiber paper is manufactured with high purity refractory fiber. The advanced technology makes the distribution of fiber very even.

l Okorder ceramic fiber paper is made with minimum bond. The ceramic fiber paper will be completely burnt during the usage.

l Ceramic Fiber Paper has great flexibility, mechanical performance, and excellent refractory and high temperature insulating performance.

Feature of Ceramic Fiber Paper

Withstand high temperature

Low thermal conductivity

Less heat storage

Resistance to thermal shock

Stabilized to most chemical

Corrosion resistance

Not easily torn

Absorb sound

Even density and thickness

Easy to install

Application of Ceramic Fiber Paper

High temperature gasket

Boiler door seal

Refractory expansion joint

Furnace backup insulation

Lining for aluminum casting molds

Thermal and electrical insulation for heaters

Acoustic and thermal insulation for automobile mufflers

Heat insulation for exhaust tubes and pipes

Electrical switch box fire protection

Image of Ceramic Fiber Paper

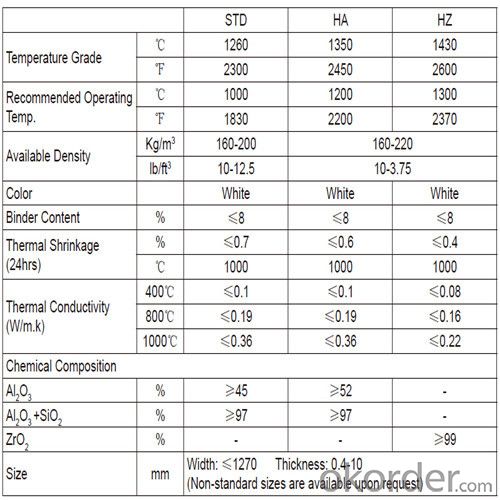

Technical Data of Ceramic Fiber Paper

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisors.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

- Q: The condition of ceramic glass fiber at high temperature

- Glass and ceramic fibers are inorganic non-metallic materials, they are silicate, can be used as structural materials that emphasize mechanical properties, but also can be used as functional materials that emphasize photoacoustic magnetic properties, but the 1. general glass is amorphous substance, the fibers are formed by melting under drawing while; ceramics is a crystal structure of the fiber by solution or melt into the crystal growth out of course, can also be formed by chemical synthesis or decomposition method;

- Q: Ceramic fiber spray and thrown silk floss, which is better?

- 1, fiber diameter: rejection fiber more coarse, rejection filament fiber is generally 3.0-5.0 mu m, spinneret fiber is generally 2.0-3.0 mu m;2, the length of fiber yarn: rejection fiber longer, the rejection of silk fiber is generally 150-250mm, spinneret fiber is generally 100-200mm;3, the coefficient of thermal conductivity: spray cotton fiber is lower than that of the thrown silk;4, the tensile and flexural strength: thrown silk because fiber thicker than that of spraying cotton;

- Q: Where is the best packing area for ceramic fibers?

- As the temperature continues to rise, the products will gradually become white, organic fiber has been completely carbonized products completely for the high temperature inorganic ceramic fiber resistant ceramic fiber (standard type) white maximum temperature ceramic fiber cloth content index color 1260 C fiber diameter 1-4 m thermal shrinkage (1232 C, 24h) 3.5% transmission rate (at 538 8pcf) three 0.130w/m.k two aluminum oxide content 45-48% 0.7-1.2% ferric oxide content of calcium oxide and sodium oxide content of 0.43% slag ball content <8.5% breakdown voltage 5 kv/mm resistance of 5 * 1010 ohm 3w.xxceramic content index white color thickness 1.5mm--6.0mm single 0.5 3kg/ square meters of organic fiber content <20% content <2% strengthening materials alkali glass fiber nichrome wire (1Cr18Ni9Ti)

- Q: What is ceramic fiber paper? What is ceramic fiber paper for?

- In order to understand what ceramic fiber paper can do, it is necessary to know what product characteristics it has. Only by knowing these advantages can we make accurate judgments about what we can do.The ceramic fiber paper is made of ceramic fiber, so the ceramic fiber paper itself contains no asbestos and can replace the carcinogenic asbestos products on the market.The raw material of the ceramic fiber paper is longer, low density, high strength, and has a certain elasticity, so it is easy to carry out stamping, cutting, winding and other construction operations. It is because of the ceramic fiber paper after high temperature firing process, so it has high temperature resistance, chemical corrosion, thermal shock, low thermal conductivity, good dielectric strength and high elastic modulus and high performance.

- Q: What is the essential difference between the standard of ceramic fiber and ordinary aluminium silicate?

- Ceramic fiber products (aluminum silicate fiber products) (1) ceramic fiber products (aluminum silicate fiber products) varieties and properties of ceramic fiber products (aluminum silicate fiber products) is the most important indicator of fiber diameter and thermal stability. Al2O3SiO2 fiber is commonly used in ceramic industry. It is divided into different application range according to the content of Al2O3, and Cr2O3 material is introduced into it to improve its refractory and oxidation resistance. Generally high alumina content, iron oxide and other impurities of low fiber products are pure white, the introduction of chromium oxide fiber is sold with milk yellow tone color. The average diameter of ceramic fiber products (aluminium silicate fiber products) is 22 - 33 microns.

- Q: What are the prospects for ceramic fiber paper and how much investment will be needed?.

- It's a good prospect. I have friends around here who specialize in this. Not much investment.

- Q: Do fiberglass or ceramic fiber paper have insulation effect?

- Second, in the case of temperature can be met, glass fiber cotton insulation better. The main advantage of ceramic fiber is to make gaskets and the like.

- Q: How to paste the ceramic fiber paper on the iron plate?

- Not used in high temperature industry, then with double-sided adhesive can be.

- Q: Why doesn't the insulation effect of ceramic fiber compound reflect the insulation board well?

- And although the ceramic fiber high temperature resistance, but in 1400 degrees when the use of life will be greatly reduced, and the thermal conductivity of the beginning as compound reflection insulation board, high temperature is higher than the compound reflection insulation board greatly.

- Q: How high is the temperature resistance of the ceramic fiber gasket?

- Ceramic fiber gasket to see what you are using material, usually refers to ceramic fiber paper made of high temperature gasket

Send your message to us

High Purity Alumina Ceramic Fiber Paper

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords