High Pure Ceramic Fiber Board Heat Insulation Anti-Fire Module 14STD

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

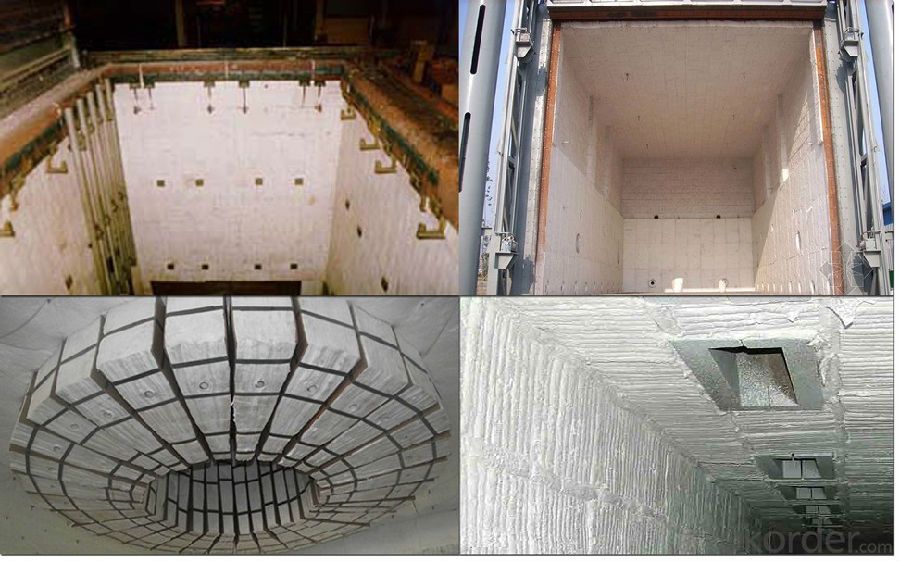

High Pure Heat Insulation Ceramic Fiber Anti-fire Module

Product Description

USAGE: 1. Open the bag to check if the coagulant agent is dampened or hardened, and then spread the coagulant agent uniformly into the bag;

Mix certain amount of the mass according to on-site assumption. When it mixes well, add room temperature water by a ratio of 6-7%, or adjust the ratio according to local climatic condition and water content of the mixture. Blend it till there is no raw ramming mass left or till that it will break into pieces instantly when it falls to the ground after one unlooses his grip of the mass from the height of 0.33 meters;

The construction site and bonder should be clean and without sundries. The leftover well-mixed mass should be covered with plastic sheet film or placed in shady and cool place. The mass that is not dry and hard can be used again; otherwise, it should be crushed and used together with other raw material or abandoned.

Mix with water to make the material likeslurry then press smooth by vibrating.

CONCRETING TIME: BEGINNING TIME: 0:15~2:00 HOURS

FINISHING TIME: 3:00~6:00 HOURS

HEATING TIME: AFTER 150:00 HOURS

THIS MATERIAL IS WITHOUT PHOSPHORUS,

AND DOES NOT POLLUTE THE ENVIROMENT.

High Pure Heat Insulation Ceramic Fiber Anti-fire Module

Product Description

USAGE: 1. Open the bag to check if the coagulant agent is dampened or hardened, and then spread the coagulant agent uniformly into the bag;

Mix certain amount of the mass according to on-site assumption. When it mixes well, add room temperature water by a ratio of 6-7%, or adjust the ratio according to local climatic condition and water content of the mixture. Blend it till there is no raw ramming mass left or till that it will break into pieces instantly when it falls to the ground after one unlooses his grip of the mass from the height of 0.33 meters;

The construction site and bonder should be clean and without sundries. The leftover well-mixed mass should be covered with plastic sheet film or placed in shady and cool place. The mass that is not dry and hard can be used again; otherwise, it should be crushed and used together with other raw material or abandoned.

Mix with water to make the material likeslurry then press smooth by vibrating.

CONCRETING TIME: BEGINNING TIME: 0:15~2:00 HOURS

FINISHING TIME: 3:00~6:00 HOURS

HEATING TIME: AFTER 150:00 HOURS

THIS MATERIAL IS WITHOUT PHOSPHORUS,

AND DOES NOT POLLUTE THE ENVIROMENT.

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- It is concluded that the test error of this method and device is about 2%. This filament ultra light aluminum silicate fiber product: the filament ultra light aluminum silicate product is by Shandong Zibo high quality burnt precious stone as raw material, passes through the smelting furnace, the rejection silk, blows the cotton, the auxiliary mold and so on to deliver the work procedure. Therefore, the thermal conductivity of fiberboard is chosen by heat flow meter method.

- Q: What are the standards for ceramic fiber boards?

- The existing ceramic fiber board has broken through the age of fear of water, and the newly developed hydrophobic ceramic fiber board has the characteristics of normal working under the water environment.

- Q: Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Sheng Yang series of ceramic fiber board is based on the traditional process of comprehensive upgrading of the excellent vacuum forming insulation materials, slag ball content of less than 3%, fiber distribution uniformity, internal and external strength consistent, size controllable.Ceramic fiber board is made by spraying superfine ceramic fiber through water washing, slag removal, fiber freezing and vacuum forming. The product has superior high temperature resistance, excellent rigidity and toughness.

- Q: What are the sound-absorbing fiber boards?

- The theory on the absorption coefficient is the best sound-absorbing board sound-absorbing effect 1 (all suck, no reflections), but in reality, this material does not exist (black holes in the universe are the sound absorption coefficient is 1, which is completely absorbed)

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The traditional ceramic fiber board has good heat insulation, high temperature resistance to certain characteristics, widely used in kiln products, but this tradition also has some shortages, low intensity, high temperature and high pressure, there are restrictions on the application of kiln stress.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board density in conventional 300-350Kg/m over 350Kg/m to fand, fand fireproof plate series.

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- Nano ceramic plate for ceramic fiber with insulating board (felt), it is a functional material with excellent properties of aerogel insulation material and has a heat shielding function, adaptation to adhesive and a variety of inorganic elements in high temperature ceramic fiber as reinforcing material, through a special process preparation.

- Q: What are the uses of ceramic fiber boards?

- Ceramic fiber board is the main use of heat insulation, fire protection, insulation to use, but also with sound absorption, noise reduction, thermal shock resistance and so on. Ceramic fiber board is mainly used in all kinds of furnace lining insulation, kiln wall lining insulation, metallurgical industry furnace fire, aluminum reduction tank, refractory brick backing.

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- Distinguishing.Ceramic silicon fiber board by long fiber silica, clay, talc, glaze etc. after 1150 degrees high temperature sintering, twenty-first Century revolutionary high-tech building materials. Characteristics: flexibility, high toughness, high strength, anti wind pressure; with homogeneous magnetized light ceramic surface, disposable, pores, anti pollution, is not easy to dust, mildew, antibacterial, deodorant, anti slip, no static, not fear of chemical erosion, such as acid, alkali, or even sulfate; fire, smoke, high temperature resistance, easy processing, cutting a hole.

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber board has the characteristics of tough, high compressive strength, excellent resistance to high temperature and excellent supporting force. The compressive strength of ceramic fiber board increases with the increase of density of ceramic fiber board.

Send your message to us

High Pure Ceramic Fiber Board Heat Insulation Anti-Fire Module 14STD

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords