Wholesale Composite Ppr Pipe - High Pressure Gre Pipe Maintenance Free

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

1.Pipe Introduction

It is the ideal product for the transportations of the chemicals, drinking water, waste water, waste gas and sewer.

2.Production Range

Any type and specification RPMP of diameter DN400-DN4000 and pressure PN0.25-PN2.5MPa can be produced. Also, we can provide the customized product according to user’s specific requirements.

3.Application

Due to its own advantages, the RPMP is used extensively in the city engineering water supply and drainage, the water supply and the drainage or the recycle water in the electric factory, the waste water treatment, the oil chemical industry and so on.

TECHNICAL DATA

Stiffness | SN3750 | SN5000 | SN10000 | ||||||

Pressure | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 |

400 | 6.1 | 6.1 | 5.9 | 6.7 | 6.7 | 6.4 | 8.1 | 8.1 | 7.87 |

500 | 7.2 | 7.2 | 7.1 | 8 | 8 | 7.7 | 11.4 | 9.6 | 9.4 |

600 | 8.7 | 8.3 | 8.3 | 9.6 | 9.6 | 9.2 | 12.1 | 11.7 | 11 |

700 | 9.7 | 9.7 | 9.4 | 11.2 | 11.2 | 10.4 | 13.8 | 13.2 | 12.5 |

800 | 11.6 | 11.3 | 10.6 | 12.8 | 12.5 | 11.7 | 15.5 | 15 | 14.2 |

900 | 13.4 | 12.5 | 11.7 | 14.8 | 13.8 | 12.9 | 19.3 | 16.4 | 15.8 |

1000 | 14.6 | 13.7 | 13 | 16.2 | 15.1 | 14.4 | 20.7 | 18 | 17.3 |

1100 | 16.1 | 14.9 | 14.2 | 17.9 | 16.5 | 15.6 | 23 | 19.8 | 18.9 |

1200 | 17.2 | 16.1 | 15.4 | 19.6 | 17.9 | 16.9 | 24.7 | 21.5 | 20.6 |

1400 | 20.4 | 18.4 | 17.7 | 22.7 | 20.5 | 19.5 | 29.2 | 24.8 | 23.8 |

1500 | 22 | 19.9 | 18.7 | 24.4 | 22.1 | 20.7 | 31.4 | 26.3 | 25.3 |

1600 | 23.6 | 21.2 | 20 | 26.2 | 23.4 | 22 | 33.7 | 28.2 | 26.9 |

1800 | 26.3 | 23.5 | 22.4 | 29.2 | 26.1 | 24.7 | 36.4 | 31.6 | 30.3 |

2000 | 27.4 | 25.4 | 23.4 | 35 | 32.4 | 29.6 | 44.7 | 37.3 | 36.1 |

2200 | 29.7 | 27.6 | 25.3 | 37.8 | 35.3 | 32.6 | 48.7 | 41.5 | 40.4 |

2400 | 32.6 | 30.3 | 28.4 | 41.8 | 38.8 | 34.6 | 53.4 | 44.6 | 42.8 |

2600 | 36.3 | 33.5 | 31.5 | 45.2 | 40.5 | 35.4 | 55.8 | 47.2 | 45.6 |

2800 | 39.6 | 36.0 | 34 | 49.4 | 45.1 | 42 | 62 | 53 | 51 |

3000 | 41.0 | 38.1 | 36.2 | 52 | 47 | 45.3 | 67 | 58.2 | 54 |

CHARACTERISTICS

1. High anti-corrosion capability, long designed service time of 20 years;

2. Good hydraulic property, smooth inner surface with absolute roughness of 0.01mm, which is far less than that of carbon steel pipe or cast iron pipe;

3. Lightweight and facility to install and transport;

4. High specific intensity and reliable mechanical performance;

5. Low thermo-conductivity and small thermo-stress, which are allowed to be used in various conditions: exposed buried or suspended, in ocean or in deserts, freezing or humid;

6. Less joints and rapid assembly design: According to concrete engineering conditions, there are a several ways of connection designed for clients to choose, which include Adhesive-bonded Plug Joint, Adhesive-bonded End-to-end Joint, Flange Joint, Plug Joint with O-ring Gasket(with key-lock) and Thread Joint etc.

7. Good electrical insulation

8. Not rust, rot or corrode, not permeate, and without consequent pollution;

9. Anti-furring and vermiculate resistance;

10.Flexible design: the pipe can be designed on the shape and function according to its conditions of usage.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

Q1.What's your sample policy?

A:We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost.

Q2.Can you produce according to the samples?

A: Yes, we can produce or modify the products according to your request.

Q3.How do you deliver the goods to my country?

A:We can provide international express, such as DHL, EMS, UPS, FedEx, etc. We select air freight and sea freight upon your requests. Quotations if without mentioning the shipping costs are shipping fee excluded.

Q4.How much does it cost to ship to my country?

A:When you goanna to place an order, please contact us, because different country has different freight.

Q5.How to get the catalogue?

A:please contact us and tell us what you are looking for.

We will try our best to meet customers' demands. Welcome you come here to visit us. We sincerely welcome partners around the world to establish business cooperation with us on the basis of mutual trust, benefit and development.

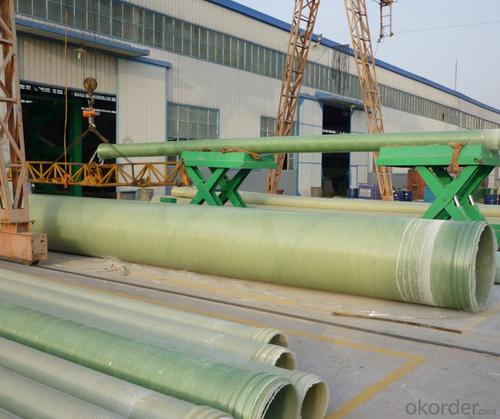

PICTURES

- Q: FRP pipe price

- The price range of raw material resin is about 10000/ tons to 60000/ tons.

- Q: The difference between FRP process tubes and GRP tubes

- Kashi Eisa's goal is to increase stiffness (large pipe defects) and reduce costs, and process tubes (mostly small tubes), these two aspects are no problems;

- Q: What kind of material does glass steel ship honeycomb board use?

- The product adopts composite honeycomb structure, prefabricated glass fiber reinforced plastic panel, high strength glass fiber grid cloth and aluminum honeycomb core material, and is compounded by hot pressing. Because of the high strength of the grid cloth, the impact resistance and flexural strength of the composite board are very high.

- Q: How to repair and repair the broken hole of GRE glass fiber reinforced plastic pipe?

- 1, clean up the broken hole around, clean; 2, find a piece of iron or glass steel film, slightly larger than the broken hole;

- Q: What is fiberglass communication tube?

- Glass fiber reinforced plastic communication tube is a kind of light, high strength, corrosion resistant and burr free metal pipe. It is mainly used for protecting cables and cables.

- Q: How is the glass reinforced septic tank and the cement drain pipe connected?

- The interface can be bonded with epoxy resin adhesive. The epoxy resin strongly adhere to the two materials, but the bonding surface must be clean.

- Q: What is the structure and function of glass fiber reinforced plastic lining?

- Repeat the process of brushing and sticking, forming three cloth, four glue or four cloth, five glue process, according to the corrosive strength of the medium, the thickness of the glass fiber reinforced plastic lining layer is different, and the price is different.FRP lining is slightly cheaper than rubber lining, but the price is only about 30% of the latter

- Q: What are the advantages of FRP pipes?

- As a result, aviation, rockets, aerospace vehicles, high pressure vessels, and other applications that need to reduce weight have excellent results. The tensile, flexural and compressive strengths of some epoxy FRP can reach over 400Mpa.

- Q: What is the thickness of all types of FRP pipes?

- The standard effective length of the tube is 6m and 12M, and the production methods include fixed length winding process, centrifugal casting process and continuous winding process of three kinds. Classification can be carried out according to the product process method, pressure grade PN and stiffness grade SN.

- Q: What kind of epoxy resin and formula do you need for making fiberglass pipe?

- By explaining the materials, tools, moulds, renovation and repair, process, structure and various products, the latest development direction, process technology and application of FRP products are described.

Send your message to us

Wholesale Composite Ppr Pipe - High Pressure Gre Pipe Maintenance Free

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords