High Polymer Polyethylene Waterproofing Membranes Production Line 120kg Per Hour Capacity

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

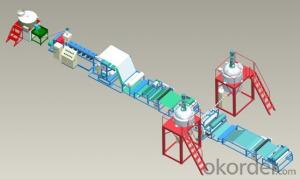

High Polymer Polyethylene Waterproofing Membrane Production Line

1.High Polymer Polyethylene Membrane Production Line Description

PE(polyethylene granules are extruded into membrane with the flat and straight extrusion die of the equipment, followed by polypropylene fiber or dacron affixed on the core membrane. This equipment can also produce self-adhesive waterproof membranes ,With the characteristics of stable performance and excellent durability, the product conforms to the national standards of GB18173.1-2006.High automatcity, low power consumption, low cost, high yield, less manual labor

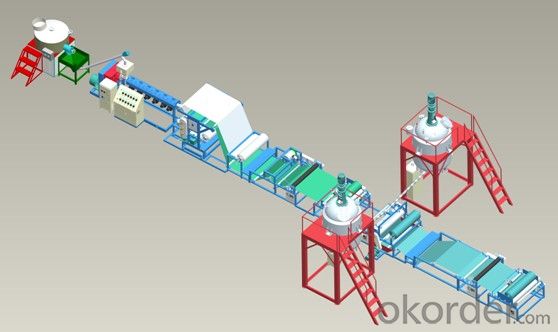

2.High Polymer Polyethylene Membrane Production Line Specification.

Model | Rated power (KW) | Output (kg/h) | Length×Width×Height | Specification | Production | |

Thickness (mm) | Width (mm) | |||||

SD-BL-100 | 130 | 120 | 19.8×7.8×4.8 |

0.5-1.5

|

1000-1200

| Polyethylene polypropylene, polyester waterproofing membrane and self-adhesive waterproof membranes. |

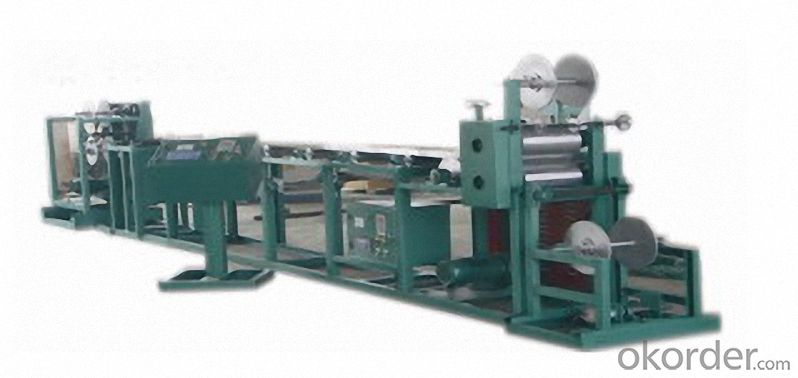

3.Technical Parameter

(1).Host adopt advanced trans-mission technology, saving electricity up to 30%.

(2).Automatic heating system had taken thick-circuit,saving electricity about 40%.

(3).Extruder SJ100 Reducer SJY250 Engine Power: 45 KW

(4).Extruder barrel can be used 38CYMOALA materials with nitriding treatment. Screw heating power is 30 KW

(5).Die can be with inner or outer heating system,power is 23KW.

(6).Three-Roller Device is horizontal or vertical style, surface of roller was with hard chrome treatment.Power is 1.1KW.

(7).Traction Device can be used wear-resistant rubber roller with torque traction. Power is 10N.M.

(8).Meters Model J250-001 Ratio is 1:3.3

(9).Winding Unit is with four-roller friction winders or Inflatable winding.Power is 0.75KW/10N.M.

(10). Self-adhesive coating system. Power:76KW

4.Products Description

High Polymer Polyethylene Polypropylene Waterproofing Membranes, High Polymer Polyethylene Polyester Waterproofing Membranes.

Polyethylene polypropylene, polyester waterproofing membrane and self-adhesive waterproof membranes.

This product is composed of extruded PE membrane with polypropylene fiber or dacron and self-adhesive covered on both sides of the core membrane as reinforced layer to make it big friction and easy to be stuck firmly to the concrete.

With characteristics of easy installation, no pollution and good durability.

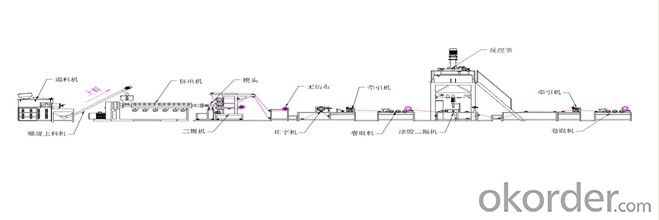

5. Flow diagram

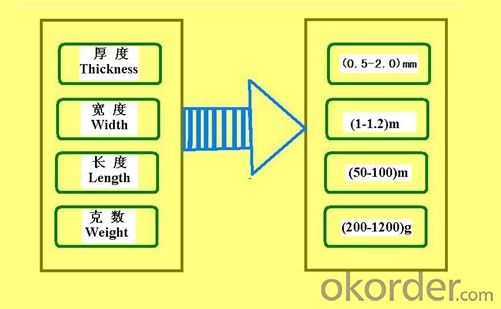

6.Products Specification

7.Application Range

Products mainly used in roofing,baseme,bathroom water, grain, bridge and other water projects.

8.Product Hall

- Q: Roofing waterproof construction machinery and equipment, how to fill out the form to inform?

- Roof construction machinery?We do ROOF MATE cool roof waterproof system, unlike traditional roofing.The plant usually in the cast-in-place board on the light directly after brushing or spraying. Don't do anything else. (without insulating layer, our product has the function of blocking the sunshine and heat, and the temperature of the roof is close to the atmospheric temperature.)With insulation (requiring insulation acceptance), we do it directly on the insulating layer. It's finished. No protective layer and so on. The input cost of the roof is about 30%, saving money, saving labor and saving the later stage maintenance.Angle grinder (uneven grinding, removal of rust, etc.)Bristles brush (butter grade)Medium and long hair rollers (for edges and corners)AgitatorAirless spraying machine

Send your message to us

High Polymer Polyethylene Waterproofing Membranes Production Line 120kg Per Hour Capacity

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords